VFINE - Extrusion Bottle Blow Blowing Moulding Making Molding Machine Machines Manufacturers extrusion blow molding machine

To keep up with the industry development, all employees of Zhongshan Vfine Machinery Co., Ltd have been doing their utmost to develop new products for days. Extrusion Bottle Blow Blowing Moulding Making Molding Machine Machines Manufacturers provides not only excellent quality, but also very favorable price. Zhongshan Vfine Machinery Co., Ltd always stick to the market-oriented business philosophy and regard 'honesty & sincerity' as the enterprise tenet. We are trying to establish a sound distribution network and aim to provide customers all over the world with the best services.

| Model NO. | CF65-2-2 | Technics | Extrusion Blow Molding Machine |

| Product | Moulding Machine | Transport Package | Wooden Package |

| Specification | 5*2.2*2.5m(L*W*H) | Trademark | VFINE |

| Origin | China | HS Code | 8477109000 |

| Production Capacity | 100set/Year |

Product Description

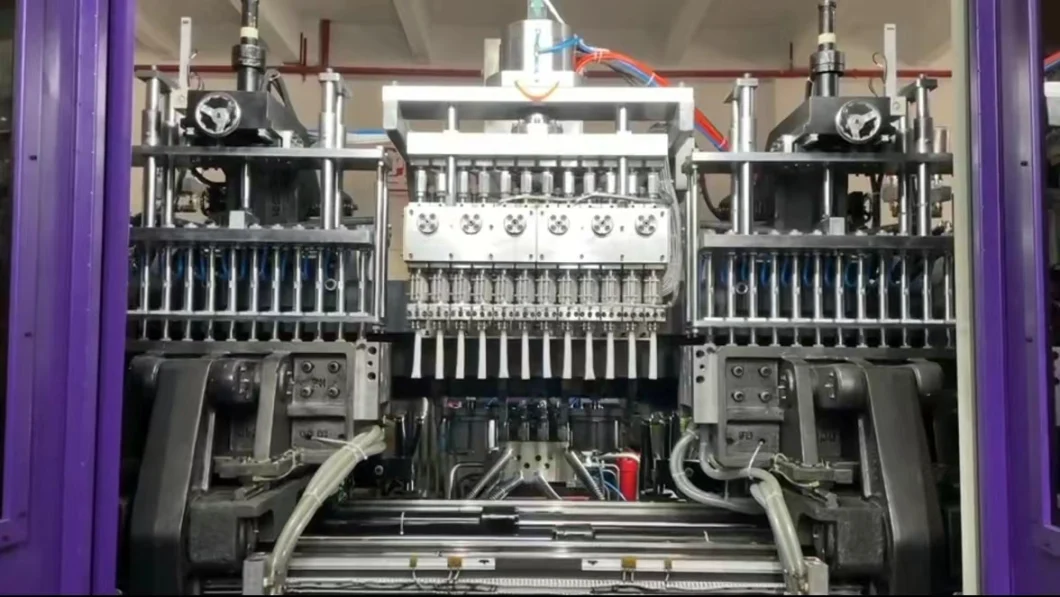

a. Extrusion system 90mm, single layer, double die-head, center distance 250mm,

double stations

b. Siemens PLC control with 7inch color touch screen, with temperature control module;

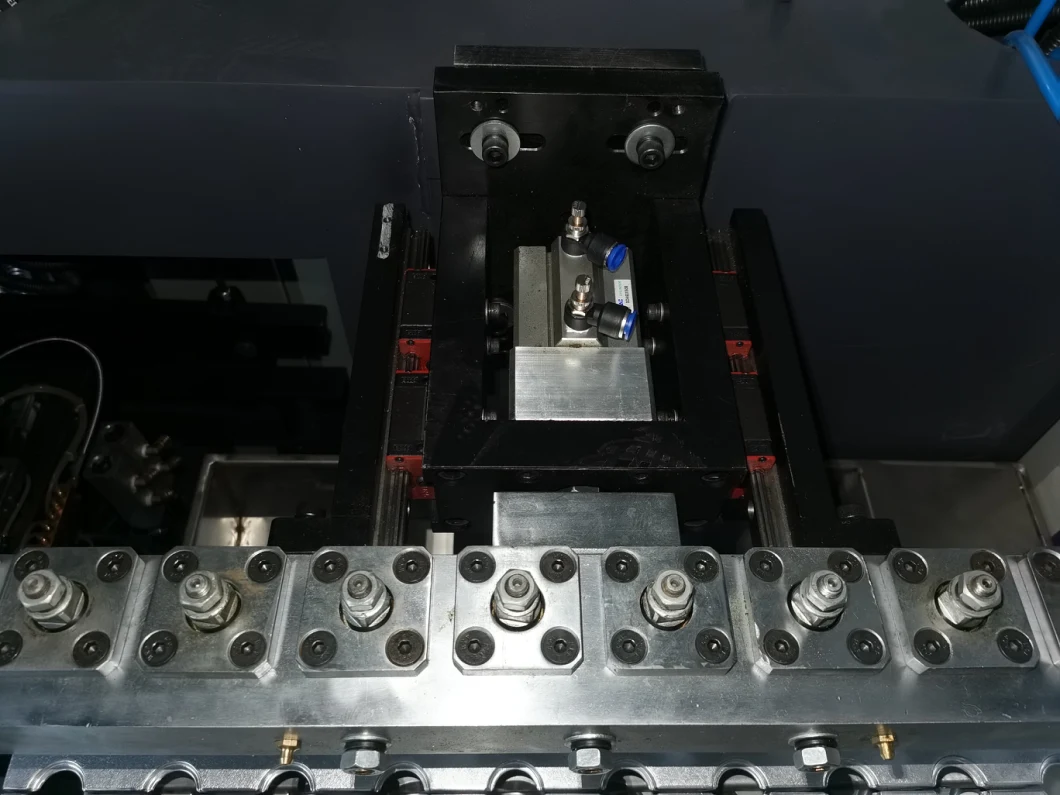

c. Platen size:H450xW600; closing stroke 230-580mm; carriage stroke:650mm

d. Clamping and carriage with full linear and toggle system

e. Taiwan Yuken oil value, manifolds electroplated.

f.Japan Sumitomo servo oil pump, INOVANCE servo motor;

g. With reducing value, clamping and carriage with full linear and toggle system

h.Japan Sumitomo servo oil pump, Inovance servo motor;

i. Auto deflasher program: including Pneumatic value and Electricity element

j. Manual platform adjustment and hydraulic die-head lifting, Whole-set machine frame design(

k. Independent 100points parison control, Yuken servo parison control value, England TR transducer;

l. Free six leveling plate for each machine

m. Lubricant oil level detect alarm system, can detect oil level reduce cause by oil leakage, and start the alarm, stop machine;

n.Machine internal maintenance light system and electric socket

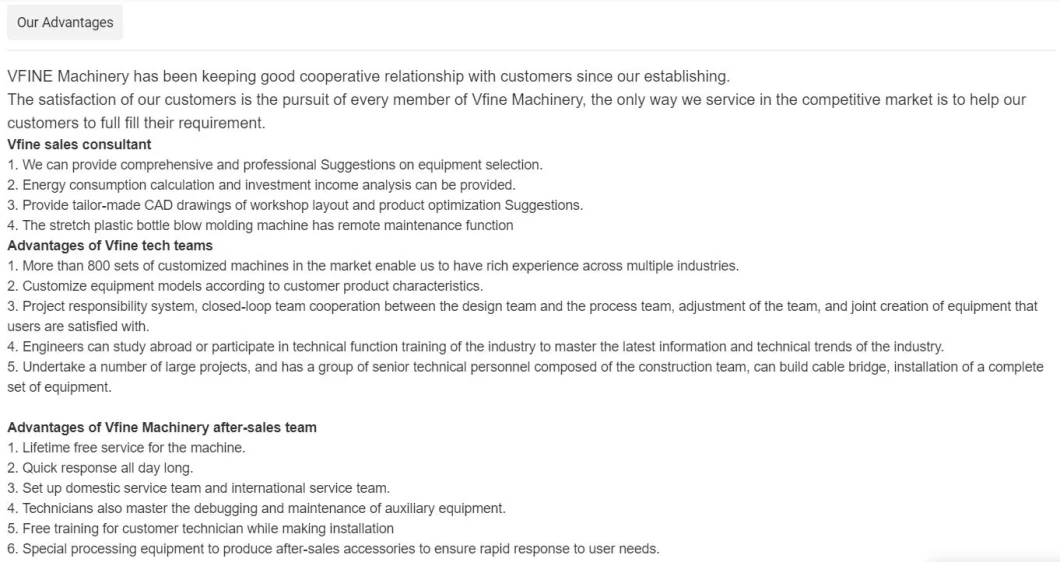

We have a professional after-sale service team, before the machine arrive, we will give consulting service about the machine's place, electricity, and water preparation works. after the machine arrives in the customer's factory, we also send the engineer for installation and make training for the customer's engineer, customer should take charge of the engineer's travel cost, board and lodging , and labor cost.

All the machines ship from vfine machinery, are well tested and with no less than 72hours continous running, and at least 1hour continous production test, which make sure that, all the equipments can be quickly make production in customer's factory.

we guarantee that, all the machine can finish installation and start production with 2days since our engineer commission, under the condition that the customer workshop meets the installation conditions.

During commission time, our engineer will make training for customer technician and workers, make sure that, the machine will be correct operated.

- Zhongshan chumful machinery co ltd is the one branch of Zhongshan Vfine machinery co ltd, which is a professional manufacturer of bottle blowing machines, that integrates the R&D, production, and sales. Since the development and design of the first generation linear automatic stretch blow molding machine, Vfine's technical team has focused in the PET market for 20 years. We've successfully supplied machines to many world-famous brands. Not only the bottle blowing machine,Vfine(CHUMFUL) also provide the turnkey plant service for all customers, we can offer from A to Z solution for all kind of plastic bottle production.

ZHONGSHAN VFINE MACHINERY CO LTD

ZHONGSHAN CHUMFUL MACHINERY CO LTD

Diana Ren