4 Cavity Blow Molding Machine: High Speed, Energy Efficient, and Durable

product high light

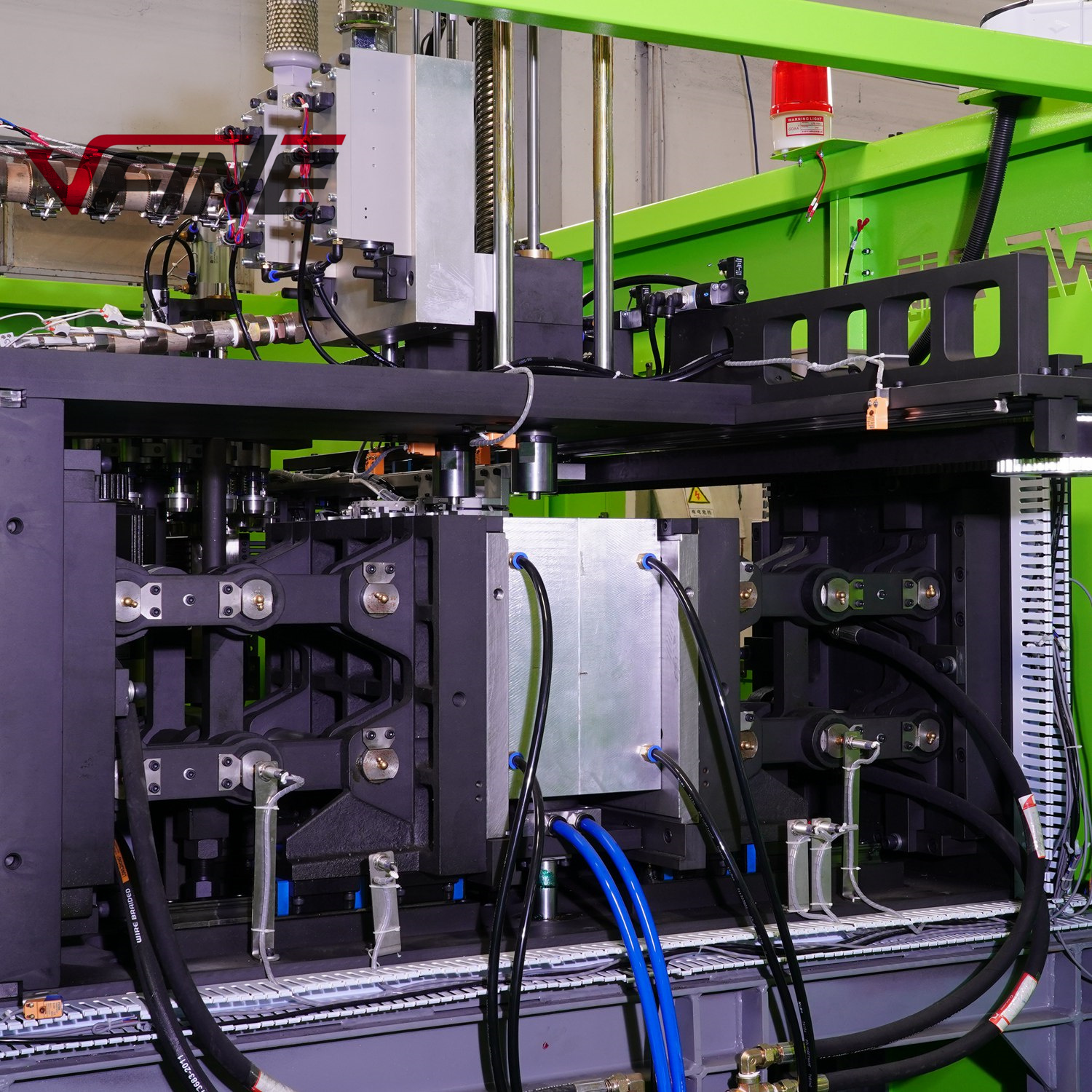

1. This is 4 cavity blow molding machine, applicated for water, milk, juice, ice tea, carbonate, medicine, shampoo bottle containers.

2. Machine production output: 8000bph

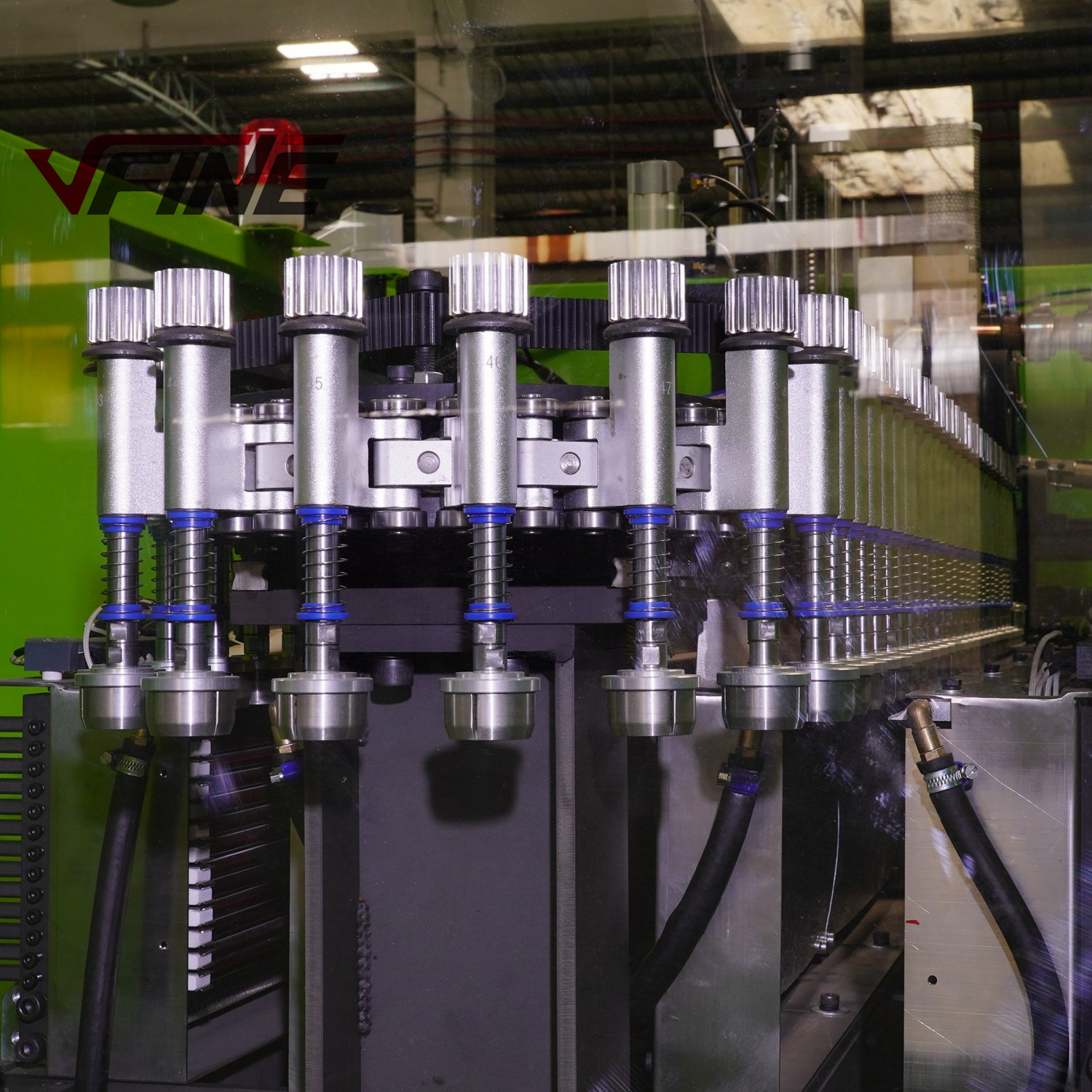

3. With full servo control, inteligent machine system, operators can finish all the operations and setting on the machine screen such as the preform heating setting, stretch rod height setting, timing setting, and shaping setting

4. The machine is very energy saving, and high efficient. It has very compact designed, occuped small space.

5. The most outstanding point is: stable running, durable, and low maintenance cost.

6. Bottle volume: 50ml-2L

Product advantages

The 4 Cavity Blow Molding Machine is designed with high speed capabilities, allowing for more efficient production cycles. Its energy-efficient design helps to minimize electricity costs, making it a cost-effective option for manufacturers. The durable construction ensures long-lasting performance and reliability, making it a valuable investment for businesses looking to improve their production processes.

Team strength

At the core of our 4 Cavity Blow Molding Machine lies a team of dedicated experts who have combined their skills and knowledge to create a high-speed, energy-efficient, and durable product. Our engineers have meticulously designed the machine to ensure optimal performance, while our customer service team is always ready to provide support and assistance. With a strong focus on teamwork and collaboration, we have been able to deliver a top-quality product that meets the needs of our customers. Trust in our team's strength to provide you with a reliable and efficient blow molding solution for your business.

Why choose us

The 4 Cavity Blow Molding Machine is a testament to team strength, combining high speed, energy efficiency, and durability in one powerful package. Designed and engineered by a skilled team of experts, this machine delivers exceptional performance and reliability for your manufacturing needs. The cohesive efforts of our team have resulted in a state-of-the-art product that sets new standards in the industry. With a focus on innovation and quality, our team has ensured that this machine is not only efficient and fast but also built to last. Choose team strength, choose the 4 Cavity Blow Molding Machine.

About VFINE

Product Introduction

The L series machine is full servo control and smart PET bottle making machine, it is avaiable for bottle from 50ml to 2L for water, milk, juice, ice tea, carbonate, medicine, shampoo containers. with single channel preform infeeding, and protect from preform get blocked, the production capacity of the equipment is not less than 2000 bottles/hour/per cavity; the equipment combines the advantages of the rotary machine and the linear machine, with a high energy utilization rate and simple and convenient operation

Product specifications

| items | High speed 4 cavity bottle blow molding machine |

| machine model | YF-L4LE |

| machine production capacity | 8000BPH |

| cavity number | 4 |

| bottle capacity | 50ml to 2L |

| actual running power | 15-20KW/H |

| machine weight | 6000kg |

| machine size | 420*190*250cm |