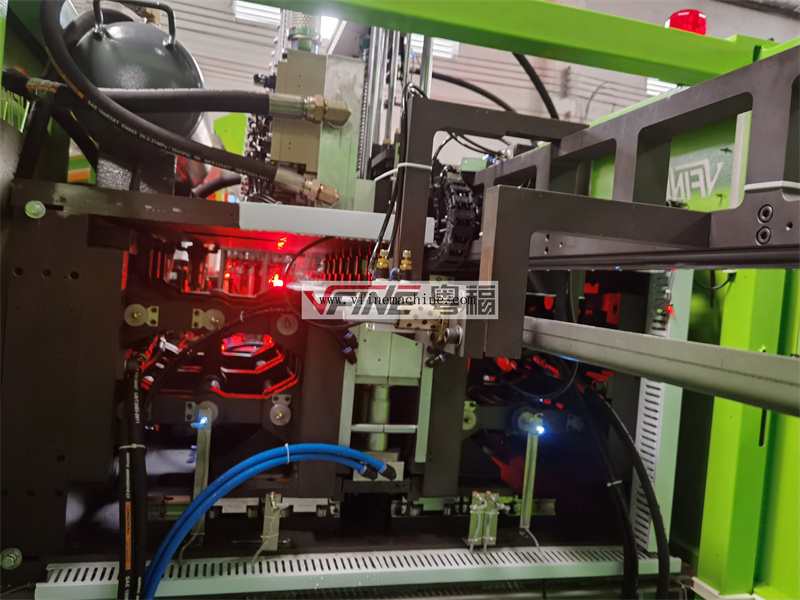

Automatic Bottle Making Machine - High Capacity, Fast Change, Energy Efficient

Product advantages

Our automatic bottle making machine offers high capacity production, allowing for increased efficiency and output. With fast change capabilities, the machine can seamlessly switch between bottle sizes and shapes, minimizing downtime. Additionally, our energy-efficient design helps reduce production costs and environmental impact.

Company profile

Our company is a leading manufacturer of automatic bottle making machines with a focus on high capacity, fast changeovers, and energy efficiency. We pride ourselves on providing innovative solutions that help businesses increase their production output while reducing operating costs. Our machines are designed to be user-friendly, allowing for easy customization and efficient operation. With a strong commitment to quality and customer satisfaction, we strive to continuously improve and refine our products to meet the evolving needs of the industry. Trust us for reliable, high-performance bottle making machines that will propel your business forward.

Enterprise core strength

Company Profile: Our company is a leading manufacturer of automatic bottle making machines with a focus on high capacity, fast changeovers, and energy efficiency. We strive to provide cutting-edge technology and innovative solutions to meet the needs of our customers in the beverage industry. With a commitment to quality and reliability, our machines are designed to increase production efficiency and reduce downtime. Our team of experienced engineers and technicians are dedicated to delivering superior performance and outstanding customer service. Trust us to bring you the best in bottle making technology for your business needs.

Vfine is a professional, experienced Source manufacturer for Bottle blow molding machine, the machines are available for all of PET bottle, with bottle capacity range from 8ml to 30L.

the machine output range from 1000BPH to 20000bph.

The 8 cavity fully automatic bottle blow molding machine specifications

- YF-L8LE

- 8CAVITY

- 50ml-2L

- 16000bph

- 380V/50HZ/3phase

91kw

- 76KW

- 30kw

- 9500kg

- 6,700*1,950*2,500 mm

Ø Energy efficient, flexible

The single chamber production capacity of the equipment is not less than 2000 bottles/hour, and the efficiency is high; the equipment combines the advantages of the rotary machine and the linear machine, with a high energy utilization rate and simple and convenient operation

Ø Fast mold change

Drawer-type mold locking structure, easy and quick mold change, no more than 30 minutes to change the mold

Ø Intelligent control system, which can complete all parameter settings, equipment operation, and troubleshooting on the touch screen.

Ø Stable equipment performance and low maintenance cost

Ø Oil-free preform transfer system, there is no risk of preform getting polluted

Ø The equipment structure design is compact, occupying a small space

Ø Powerful temperature control system can ensure constant heating output and ensure the stability of preform heating

Ø The whole machine frame and clamping plates are annealed, and the plane and hole processing are completed at one time in the CNC machining center to ensure that the machine frame and template are accurate, non-deformed, and durable.

Ø Powerful cooling system to ensure that the thin-walled preform neck bottles and light-weight bottles are not deformed.

- Are you a trading company or a manufacturer?Vfine(CHUMFUL) is a professional manufacturer for PET bottmachinesine, we also provide turnkey plant consultiservicesice for PET bottle production line, pet bottled water, and beverages production line for customers.

- What's your guarantee or the warranty of the quality if we buy your machines?All of Vfine machines are guaranteed at least one year, and we provide whole lifetime service for all customers, within the quality guarantee time, free offer wearing parts, and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to the seller's demand, and debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still cannot solve, we will arrange technician to your factory to solve the problems. The cost of technician arrangement you could see the cost treatment method of technician. After guarantee time, we offer technical support and after-sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, and debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still cannot solve, we will arrange technician to your factory to solve the problems

- When can I get my machine after I paid?We will deliver the machines on time according to the date we agreed on both sides.

- How can I install my machine when it arrives?before machine shipments, we have all marks for the future machine installation, take vdos for reference. For almost all of our old customers, can manage to install the machine under the vdo guide and on-line service. For all new customers and those who cannot handle the installation, we send engineers to the customer's factory to make the installation. Meanwhile, we will make training for customer technician and machine operators.

- What's the delivery time?45-90 days after receipt of the deposit.

- Where is your factory located?Vfine locates in Zhongshan city, which is 1 hour away from Guangzhou airport and 2 hours away from Shenzhen airport.

- How is your machine quality?Our R&D engineer started to design and develop the PET blowing machine since 2001 for the first generation automatic linear PET bottle blowing machine, who have plenty of experience in the PET Bottle market, we keep improving the machine detail design and machine quality, till now we have successful cooperation with many world-famous brand, which also make us keep moving on for machine performance and let us take very serious control for our machine quality.

- Can you make the bottle design?Vfine(CHUMFUL) technical team not only make design of our machine, we also provide bottle design and bottle function testing for all customers.

- What is the language of the PLC and touch panel?we provide English, Spanish, Russian and Chinese version in the screen.

- What is the standard of package?Export standard package or special package according to customer requirement.

- Do you accept OEM business?Yes, we are OEM supplier.

- which kind of certificate do you have?We have ISO9001, CE Certificate

For more information, You may contact us at any time.

- Company NameZhongshan Vfine Machinery Co., Ltd