Automatic Pet Plastic Water Bottle Blow Molding Machine at 9000bph

Product advantages

The Automatic Pet Plastic Water Bottle Blow Molding Machine at 9000bph offers the convenience of rapidly producing up to 9000 bottles per hour, making it highly efficient for large-scale production. Its advanced technology ensures consistent quality and precision in every bottle produced, giving businesses a reliable and high-performance solution. With its user-friendly interface and robust construction, this machine is an essential tool for companies looking to streamline their production processes and meet market demands effectively.

We serve

At our core, we serve pet owners and manufacturers looking for efficiency and reliability in their production process. Our Automatic Pet Plastic Water Bottle Blow Molding Machine boasts a production capacity of 9000 bottles per hour, ensuring seamless operations and high output. We serve by providing cutting-edge technology and top-of-the-line equipment to meet the demands of the pet industry. Our dedication to quality and innovation sets us apart, as we aim to serve our customers with precision and excellence. Trust us to serve your needs and elevate your production capabilities with our advanced machinery.

Enterprise core strength

At our company, we serve by offering high-quality Automatic Pet Plastic Water Bottle Blow Molding Machines that operate at an impressive speed of 9000 bottles per hour. Our products are designed to meet the demands of the market, providing efficiency and reliability for your production needs. With a focus on innovation and advanced technology, we strive to deliver exceptional performance and results to our customers. We serve by providing top-notch customer service and support, ensuring a seamless experience from purchase to operation. Trust us to serve you with excellence in every aspect of your business.

The core competitiveness of a company is its capabilities in research and development.Zhongshan Vfine Machinery Co., Ltd, as a technology-driven enterprise, has been striving forward to enhance our R&D capabilities and successfully developed Pet Plastic Mineral Water Tank Bottle Stretch Blow Blower Blowing Molding Making Moulding Manufacturing Machine Machinery at 9000bph Fully Automatic. Blow Molding Machine has passed a series of international quality assurance system and product safety certification . Relying on our excellent products and sensible marketing strategy,Zhongshan Vfine Machinery Co., Ltd hold a firm belief that we will take a large market share in the future and benefit our stakeholders as well.

| Model NO. | YF-6E | Making Method of Parison | Stretch Blow |

| Automation | Automatic | Computerized | Computerized |

| Certification | CE, ISO9001:2008, GMP | After-sales Service | Includes |

| Product | Plastic Machinery | Transport Package | Wooden Package |

| Specification | 5*2*2.5m(L*W*H) | Trademark | vfine |

| Origin | China | HS Code | 8477109000 |

| Production Capacity | 100set/Year |

Product Description

plastic machinery

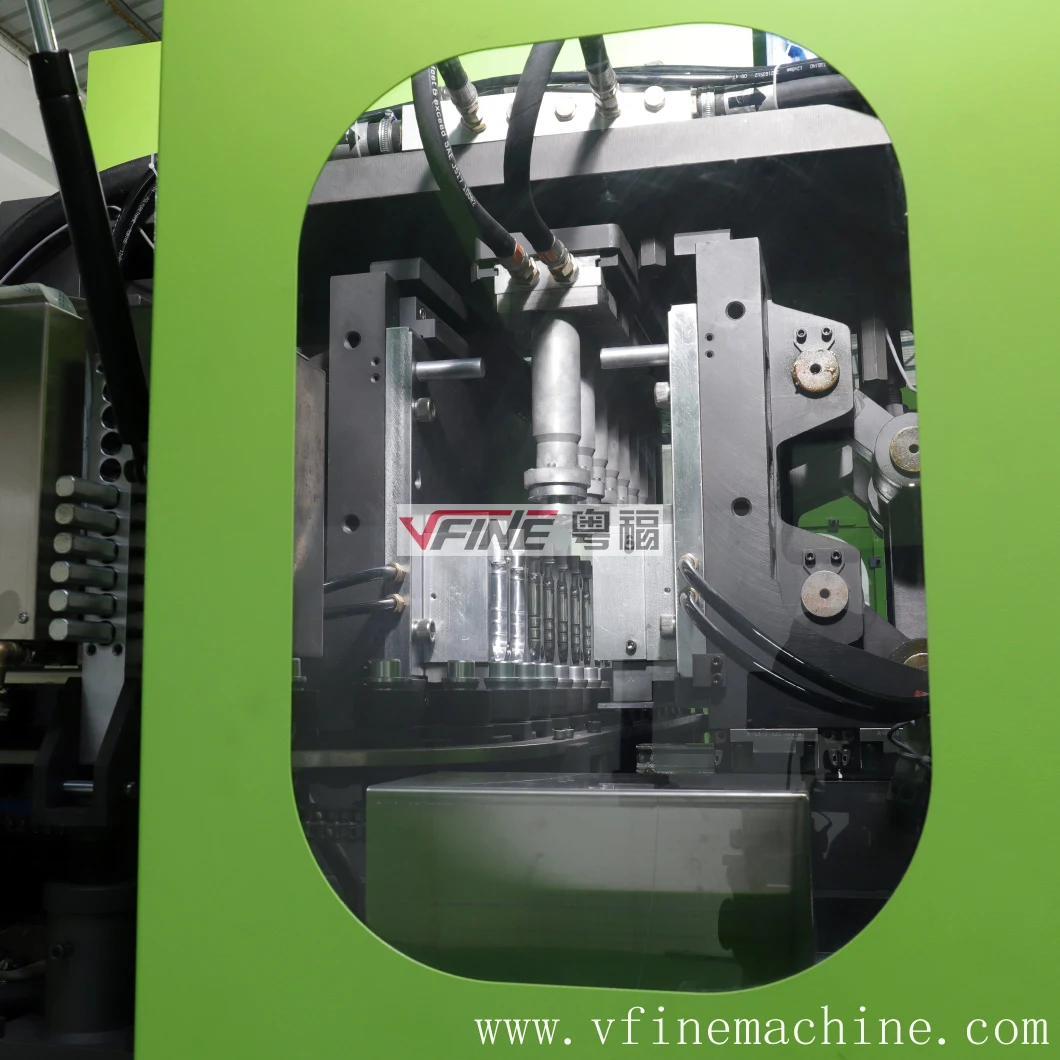

(1)Vfine blowing machine YF-6E

6-cavity, linear stretch blowing molding machine

Output: 8500-9000bph

Max. Volume: 0.6L

(2)application scope

Suitable for producing PET water bottle, carbonate bottle, middle temperature filling bottle etc.

(4) Vfine blowing machine YF-6E specifications

| MODEL | YF-6E |

| Max Bottle Volumn | 600ml |

| Cavity number | 6 |

| output | 8500-9000BPH |

| Machine size | 4000*2000*2500mm |

| Machine weight | 6500kg |

| MODEL | YF-4LE |

| Max Bottle Volumn | 2000ml |

| Cavity number | 4 |

| output | 5500-6000BPH |

| Machine size | 4000*2000*2500mm |

| Machine weight | 6500kg |

Advantages of Vfine Machinery after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment.

5. Free training for customer technician while making installation

6. Special processing equipment to produce after-sales accessories to ensure rapid response to user needs.

(3)advantage of full electrical Vfine blowing machine

Linear structure, modular design, easy maintenance;

Full servo system

Easy change mould

Save energy

High efficiency

The machine includes auto-lubricating system; ensure the machine running stable and efficiency.

Safety

The machine includes safety protecting device, ensure production security.

Vfine sales consultant

1. We can provide comprehensive and professional Suggestions on equipment selection.

2. Energy consumption calculation and investment income analysis can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product optimization Suggestions.

4. The stretch plastic bottle blow molding machine has remote maintenance function

Advantages of Vfine tech teams

1. More than 800 sets of customized machines in the market enable us to have rich experience across multiple industries.

2. Customize equipment models according to customer product characteristics.

3. Project responsibility system, closed-loop team cooperation between the design team and the process team, adjustment of the team, and joint creation of equipment that users are satisfied with.

4. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry.

5. Undertake a number of large projects, and has a group of senior technical personnel composed of the construction team, can build cable bridge, installation of a complete set of equipment.

Advantages of Vfine Machinery after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment.

5. Free training for customer technician while making installation

6. Special processing equipment to produce after-sales accessories to ensure rapid response to user needs.

Q: is the blowing machine suitable for CSD bottle

A: yes, the machine is available for water bottle, edible oil bottle, csd bottle, medicine bottle, wine bottle, etcQ: is the blowing machine full electrical

A: the machine is control by full servo for all units, no need prepare low pressure air for the blowing machine

Q: is the blowing machine available for different bottle mold

A: yes, the machine is designed with very easy bottle mold change unit, only need 30minutes to change a mold