Extrusion Blow Molding Machine: Trusted Quality Guaranteed

Product advantages

Our Extrusion Blow Molding Machine offers unmatched quality and reliability, ensuring superior performance and durability. With a focus on precision engineering and advanced technology, our machine guarantees consistent and high-quality production. Its user-friendly design and efficient operation make it the perfect choice for any manufacturing needs.

Company profile

Established in 2006, our company is a trusted manufacturer of extrusion blow molding machines, known for our commitment to quality and reliability. With a strong focus on innovation and cutting-edge technology, we provide industry-leading solutions to meet the needs of our global clientele. Our team of experienced engineers and technicians ensures that every machine we produce is built to the highest standards, guaranteeing optimal performance and longevity. With a dedication to customer satisfaction and a track record of excellence, we are proud to offer a range of high-quality products that are backed by our reputation for superior quality and service.

Enterprise core strength

With a proud history of manufacturing excellence and a commitment to providing top-quality machinery, our company specializes in producing highly reliable extrusion blow molding machines. Our team of experts is dedicated to ensuring that each machine meets the highest standards of quality and performance. From our innovative design and precision engineering to our exceptional customer service, we strive to deliver trusted quality guaranteed with every product we produce. With a focus on meeting the needs of our customers and exceeding their expectations, we are proud to be a leader in the industry, offering cutting-edge solutions for all your blow molding needs.

Vfine Machine is proud to provide consistent quality HDPE bottle making machine and dependable service for many years. The technology greatly improves product performance and accelerates the manufacturing process.It has a considerably expanded application range and is popular in the field(s) of Blow Molding Machine. We have an experienced team consisting of several industry experts. They have years of experience in manufacturing and designing extrusion blow molding machine. In the past time, they have been focusing on improving the practical use of the product, and finally they made it. Proudly speaking, our product enjoys a wide application range and can be very useful when applied in the field(s) of bottle blow molding machine.

| Model NO. | 85H+S3x2.10BM | Making Method of Parison | Extrusion-Blow Molding |

| Automation | Automatic | Computerized | Computerized |

| Certification | CE, ISO9001:2008 | After-sales Service | Life Time Service |

| Transport Package | Wooden Package | Specification | 5m*2m*2.5m(l*w*h) |

| Trademark | chumful | Origin | China |

| HS Code | 8477401000 | Production Capacity | 100set/Year |

| Package size per unit product | 500.00cm * 200.00cm * 250.00cm | Gross weight per unit product | 7000.000kg |

Product Description

PRODUCTION CAPACITY :1000 ML

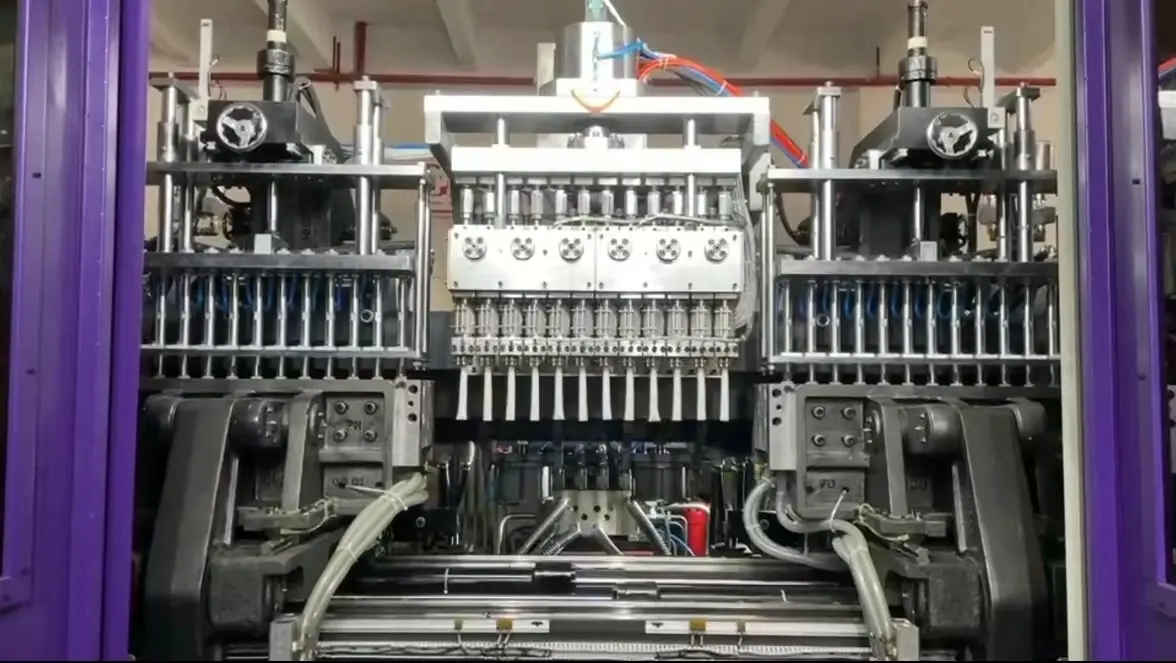

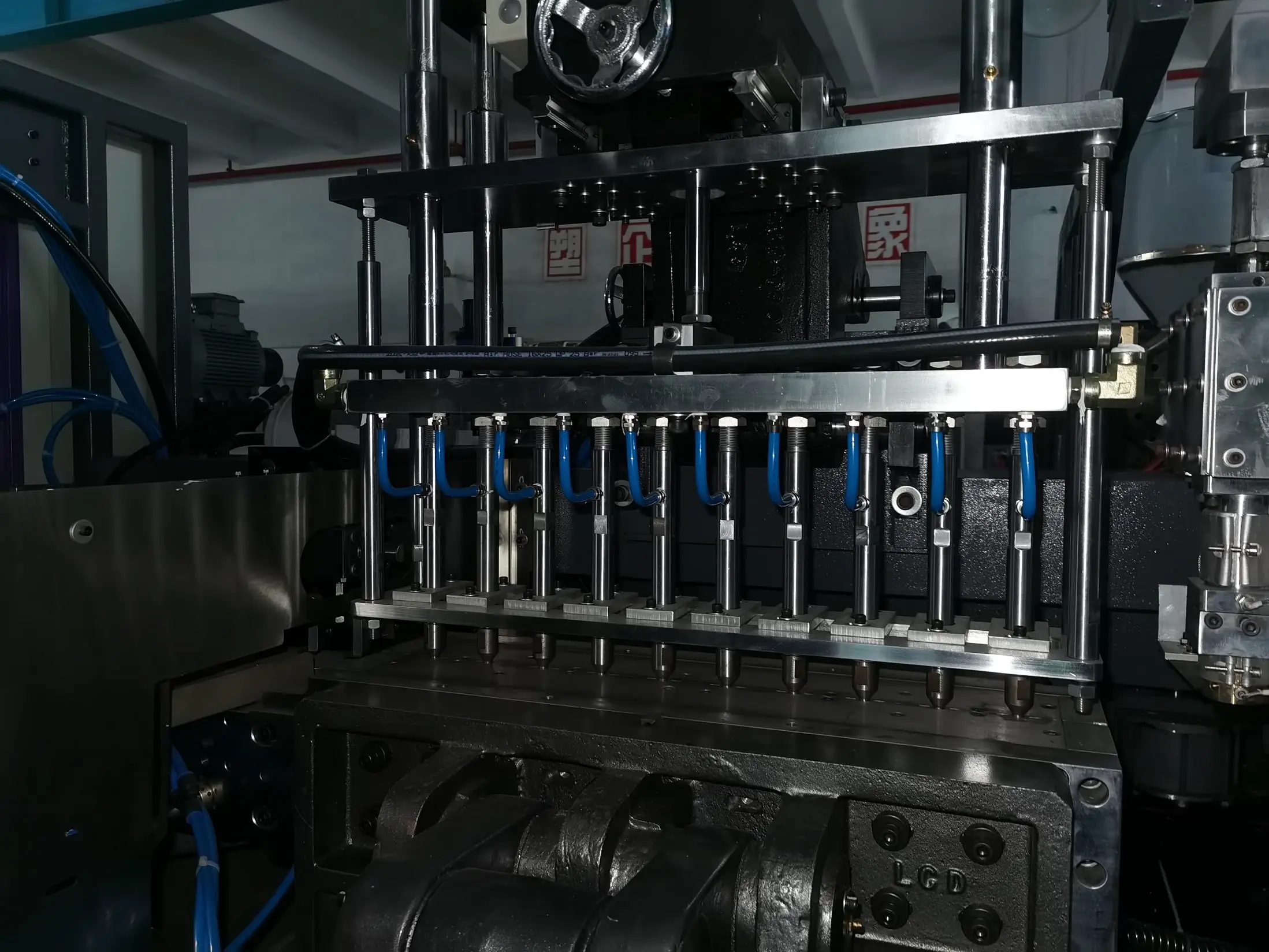

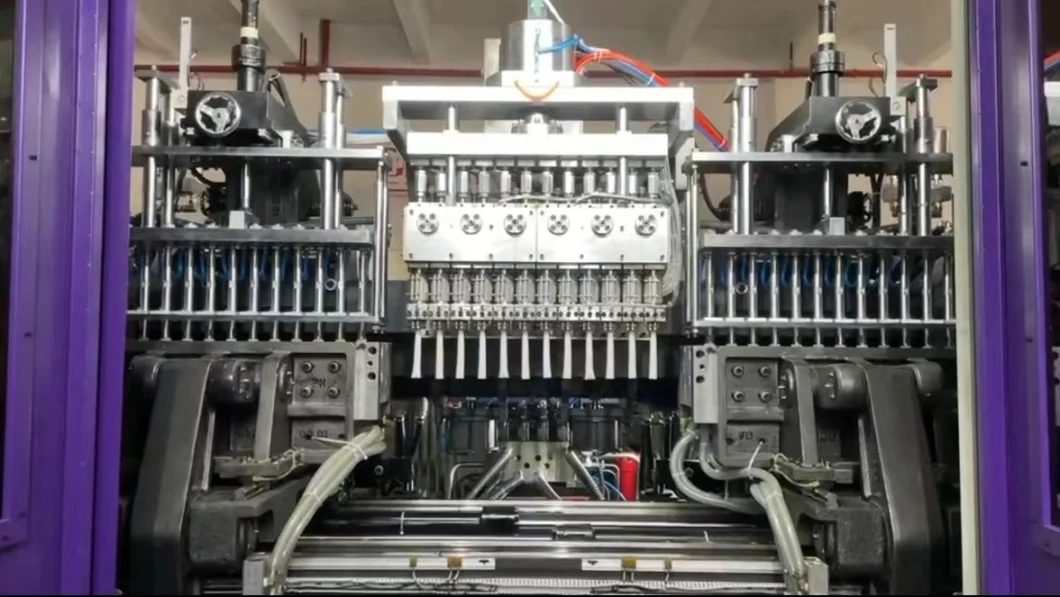

1.Extrusion system 85mm, single layer, triple die-head, center distance 150mm, double stations

2.Siemens PLC control with 7inch color touch screen, with temperature control module;

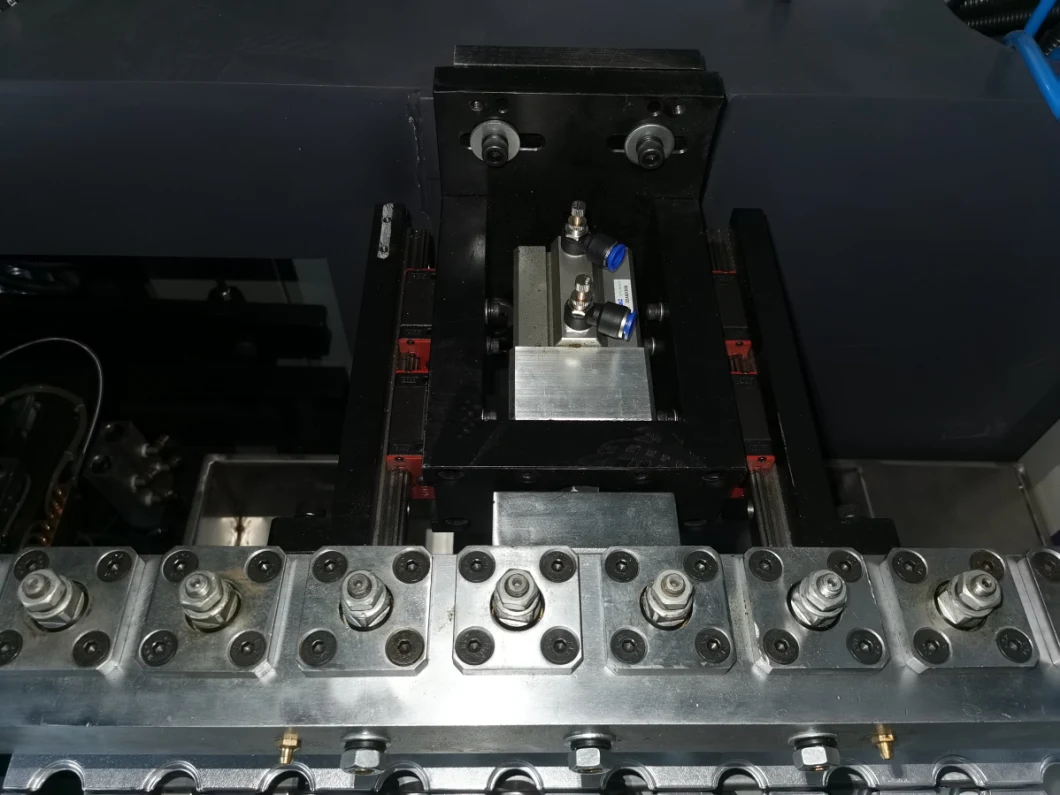

3.Platen size:H450xW400; closing stroke 230-580mm; carriage stroke:650mm

4.Clamping and carriage with full linear and toggle system

5.Taiwan Yuken oil value, manifolds electroplated.

6.Japan Sumitomo servo oil pump, INOVANCE servo motor;

7.With reducing value, clamping, and carriage with full linear and toggle system

8.Auto deflasher device: cutting knife with Japan import steel

9.Manual platform adjustment and hydraulic die-head lifting, Whole-set machine frame design

10.Independent 100points parison control, Yuken servo parison control value, England TR transducer;

11.Free six leveling plates for each machine

12.Lubricant oil level detect alarm system, can detect oil level reduce caused by oil leakage, and start the alarm, stop machine;

13.Machine internal maintenance light system and electric socket

Application:

The Vfine Machine /PP/PC/HDPE blow moulding machine is widely applied in manufacturing various plastic containers. It efficiently produces jerry cans, bottles, and containers for industries like chemicals, cosmetics, food, and pharmaceuticals. The machine handles HDPE, PP, and PC materials, ensuring durability and chemical resistance. It’s suitable for different capacities, from small bottles to large jerry cans, with precise design for leak-proof structures. Ideal for mass production, it combines high efficiency and reliability.

We have a professtional after-sale service team, before machine arrive, we will give consulting service about the machine place, eletricity, and water prepare works. after machine arrive in customer factory, we also send engineer for installation, and make training for customer's engineer, customer should take charge of the engineer travel cost, board and lodging and labor cost.

Not only blow machine, we also provide turnkey project service of pet bottle design, PET bottling equipment line, PET bottle filling, and packing.

A: yes, the machine is available for 3L-10L water bottle, edible oil bottle, etc

Q11: is the blowing machine full electrical

A: the machine is control by full servo for all units, no need prepare low pressure air for the blowing machine

Q12: is the blowing machine available for different bottle mold

A: yes, the machine is designed with very easy bottle mold change unit, only need 30minutes to change a mold

zhongshan vfine machinery co ltd

zhongshan Chumful machinery co ltd