Full Servo 8-Cavity Water Bottle Manufacturing Machine - 16000bph

Product advantages

The Full Servo 8-Cavity Water Bottle Manufacturing Machine - 16000bph boasts a high production capacity of 16,000 bottles per hour, making it ideal for large-scale manufacturing operations. Its full servo system ensures precise control and consistency in bottle production, resulting in top-quality bottles every time. The 8-cavity design allows for efficient and fast production, maximizing productivity and profitability for businesses.

Team strength

Team strength is at the heart of our Full Servo 8-Cavity Water Bottle Manufacturing Machine. Our team is comprised of experts in the fields of engineering, design, and manufacturing, ensuring that each machine is built to the highest quality standards. With a combined wealth of experience and a commitment to excellence, our team works collaboratively to deliver a product that is reliable, efficient, and innovative. From concept to completion, our team's strength lies in their dedication to pushing boundaries and exceeding expectations. When you choose our machine, you are not just investing in a product, but in a team that is dedicated to your success.

Enterprise core strength

Team strength is at the heart of our Full Servo 8-Cavity Water Bottle Manufacturing Machine, capable of producing an impressive 16000 bottles per hour. Our dedicated team of experienced engineers and technicians have worked tirelessly to perfect the design and functionality of this state-of-the-art machine, ensuring high efficiency and reliability in every production run. With a focus on innovation and problem-solving, our team is constantly striving to exceed customer expectations and push the boundaries of water bottle manufacturing technology. When you choose our machine, you are not just investing in cutting-edge equipment, but in a team that is committed to delivering excellence.

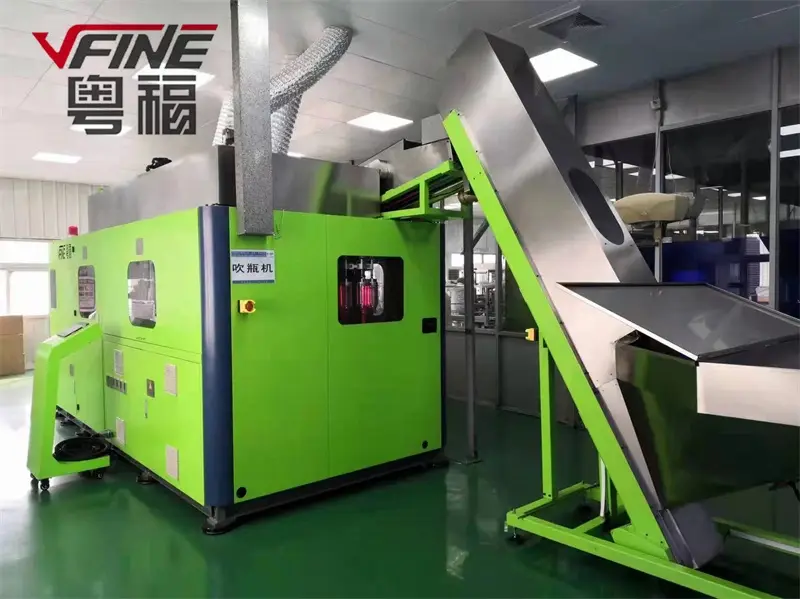

With years of development, VFINE occupies an important position in the Bottle Blowing Machine industry now. We are always in strict accordance with the international quality standards and quality management system, totally ensuring the product quality. The product is characterized by multiple advantages.Its application ranges have been expanded to the Bottle Blowing Machine. The design is the most striking aspect of VFINE. Its design comes from our designers who are sensitive to fashion and are know the commercial needs of the market very well. Also, blow molding machine made of well-selected raw materials.

| Model NO. | YF-L8LE | After-sales Service | Life Time Service |

| Product | Blowing Machine | Machine Capacity | 14000bph |

| Machine Type | Full Servo | Raw Material | Pet |

| Making Method of Parison | Stretch Blow | Automation | Automatic |

| Computerized | Computerized | Certification | CE, ISO9001:2008, QS |

| Transport Package | Wooden | Specification | 7.2m*2m*2.5m(l*w*h) |

| Trademark | vfine | Origin | China |

| HS Code | 8477109000 | Production Capacity | 50-100set/Year |

| Package size per unit product | 720.00cm * 200.00cm * 250.00cm | Gross weight per unit product | 8500.000kg |

Product Description

Zhongshan Vfine Machinery co ltd

(1)Vfine blowing machine YF-L8LE

8-cavity, linear stretch blowing molding machine

Output: 16000bph

Max. Volume: 2L

8-cavity, linear stretch blowing molding machine

Output: 16000bph

Max. Volume: 2L

the machine is with full servo, intensively heating, it intergrate the advantage of PET linear blow molding machine and rotary blowing machine. high efficience, high quality, smart design for worker's operation, and durable.

(2)application scope

Suitable for producing PET water bottle, carbonate bottle, middle temperature filling bottle etc.

(3)advantage of L-series Vfine blowing machine

save energy :

Save space:

high efficiency:

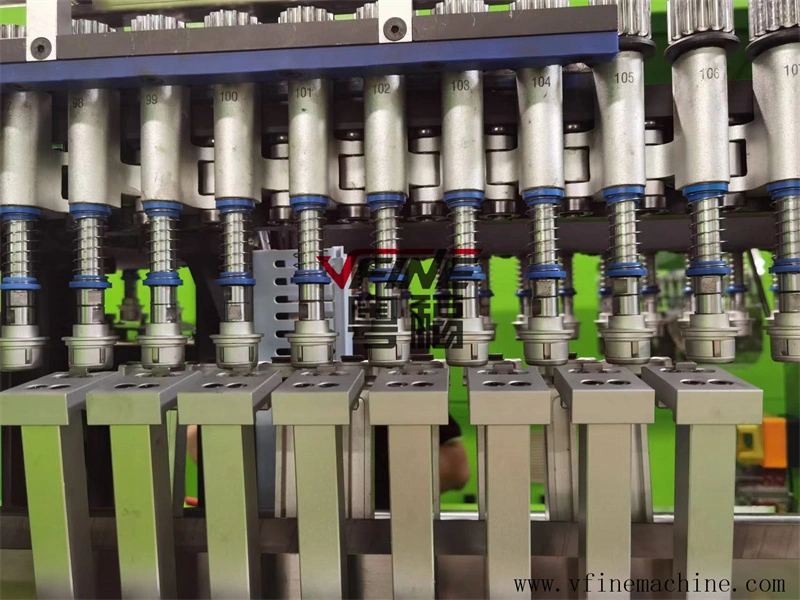

Infeeding system:

Heating system:

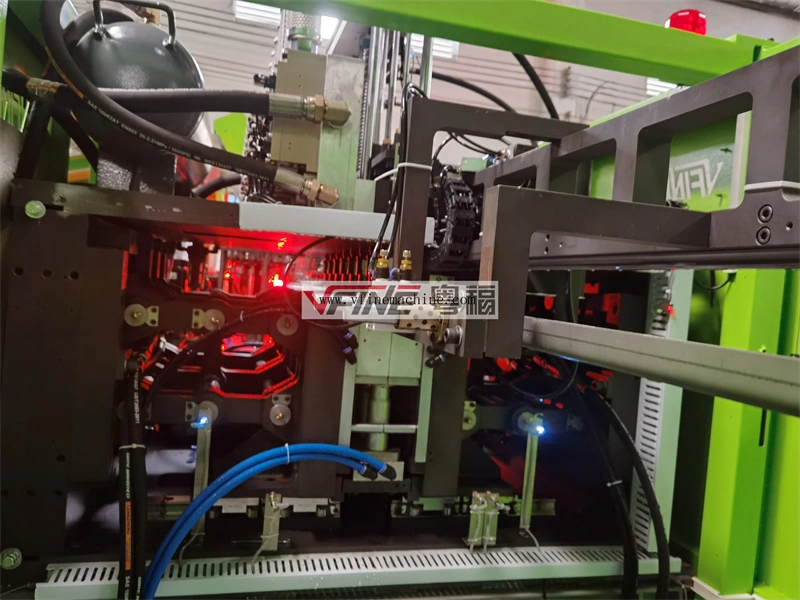

Transfer unit: The variable pitch device is controlled by servo for stable and accurate transferring.

Clamping unit: The clamping unit is controlled by servo motor to ensure the synchronization, stable running and precise location.

High pressure air recycle system: The high pressure air recycle system save the high pressure to the tank, reduce the noise and save energy lost.

(4) Vfine blowing machine YF-L8LE specifications

| MODEL | YF-L8LE |

| Max Bottle Volumn | 2000ml |

| Cavity number | 8 |

| output | 16000BPH |

| Machine size | 7100*2000*2500 |

| Machine weight | 8500kg |

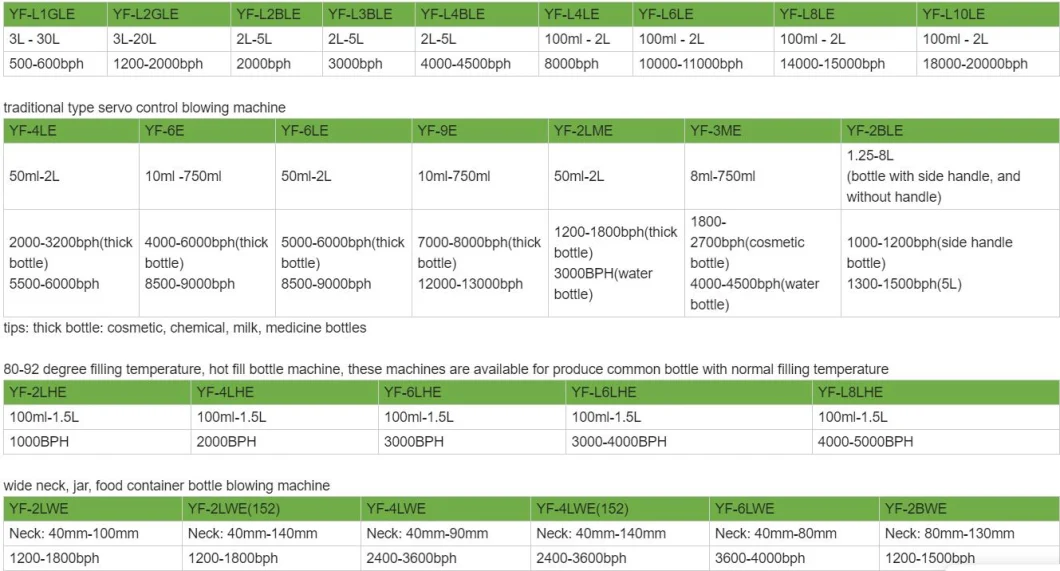

VFINE MACHINERY PRODUCT LIST SHORT VIEW

We have a professtional after-sale service team, before machine arrive, we will give consulting service about the machine place, eletricity, and water prepare works. after machine arrive in customer factory, we also send engineer for installation, and make training for customer's engineer, customer should take charge of the engineer travel cost, board and lodging and labor cost.

Not only blow machine, we also provide turnkey project service of pet bottle design, PET bottling equipment line, PET bottle filling, and packing.

A: yes, the machine is available for 3L-10L water bottle, edible oil bottle, etc

Q11: is the blowing machine full electrical

A: the machine is control by full servo for all units, no need prepare low pressure air for the blowing machine

Q12: is the blowing machine available for different bottle mold

A: yes, the machine is designed with very easy bottle mold change unit, only need 30minutes to change a mold

zhongshan vfine machinery co ltd

zhongshan Chumful machinery co ltd