HDPE Bottle Making Machine - Advanced Technology Manufacturing

Product advantages

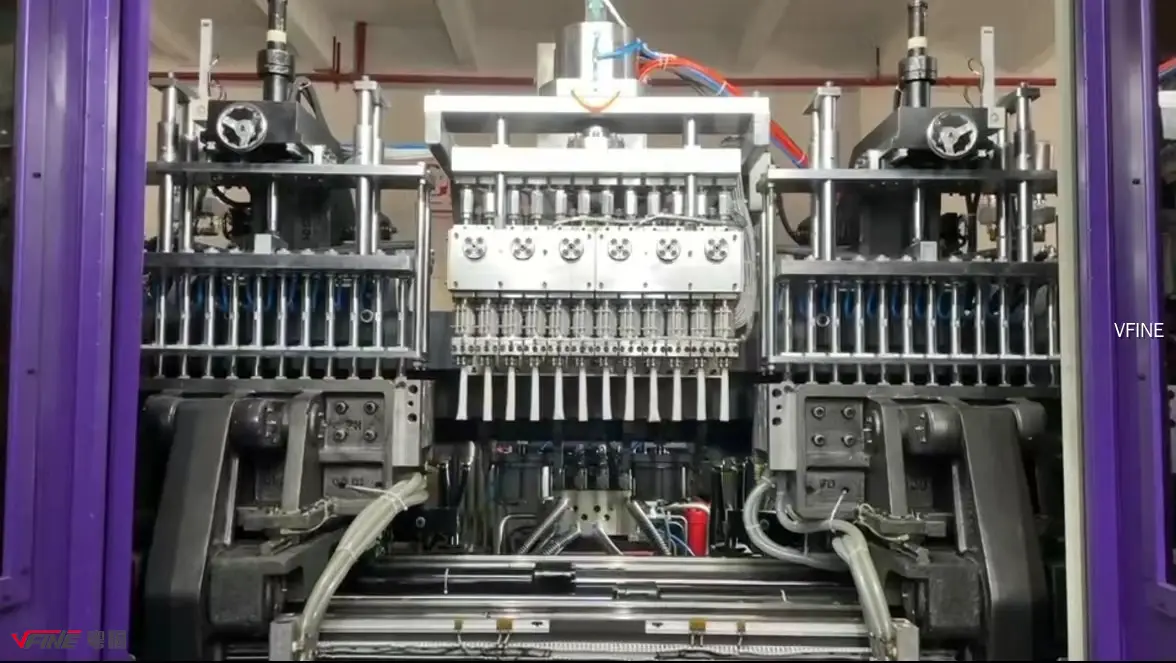

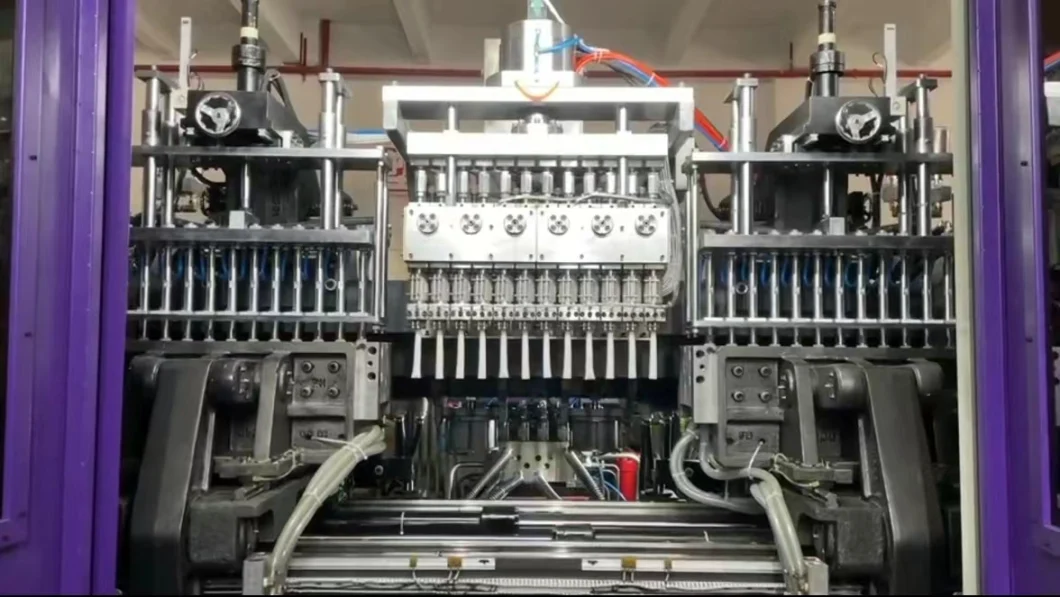

This HDPE Bottle Making Machine utilizes advanced technology in its manufacturing process, resulting in high efficiency and precision in creating bottles. Its state-of-the-art features allow for seamless production of a wide range of bottle designs and sizes, catering to various industry needs. The machine's durable construction and user-friendly interface make it a reliable and cost-effective solution for businesses looking to enhance their bottle production capabilities.

Company profile

Our company is a leading manufacturer of HDPE bottle making machines, utilizing advanced technology and the latest manufacturing processes. With a strong focus on innovation and quality, we strive to provide our clients with top-of-the-line machinery that meets their needs and exceeds their expectations. Our team of experts is dedicated to continuous improvement, ensuring that our products are always up-to-date and at the forefront of the industry. With a commitment to customer satisfaction and a reputation for excellence, we are proud to be a trusted partner for businesses looking to enhance their production capabilities with reliable and efficient HDPE bottle making machines.

Why choose us

With a strong emphasis on innovation and advanced technology manufacturing, our company specializes in producing high-quality HDPE bottle making machines. With a reputation for excellence in the industry, we are dedicated to providing efficient and reliable solutions for our customers. Our team of experts constantly seeks to improve and adapt our machines to meet the ever-changing demands of the market. We prioritize quality, performance, and customer satisfaction in everything we do. Trust in our company to deliver cutting-edge technology and top-notch service for all of your bottle-making needs.

Vfine Machine has made immense progress in the development of bottle molding machine. Fully automatic HDPE blow molding machine is the product of our company made by the state-of-the-art technologies. The team uses the most advanced production equipment and independent research and development technology to minimize bottle moulding machine development cycle and ensure the high quality and strong reliability of the product. We will fully act on the important thought of the 'quality first and customer foremost' and keep pace with the times to promote the innovation capabilities of our company. We will forge valiantly ahead and achieve our goal of being the leading enterprise in the global water bottle making machine market.

| Model NO. | 75-25H+S1X2.10 | After-sales Service | Life Time Service |

| Transport Package | Wooden Package | Specification | 7.2m*2m*2.5m(l*w*h) |

| Trademark | chumful | Origin | China |

| HS Code | 8477401000 | Production Capacity | 100set/Year |

| Package size per unit product | 400.00cm * 220.00cm * 250.00cm | Gross weight per unit product | 8500.000kg |

Key Advantages:

Precision Control: Equipped with a 100-point thickness control system using Japanese YUKEN servo valves and British TR sensors, ensuring consistent bottle quality and reducing waste.

Full Automation: Fully servo-controlled operation simplifies the production process, making it user-friendly and efficient. All settings and processes can be managed through an intuitive interface.

Energy Efficiency: Designed for low power consumption, the HDPE blow molding machine is compact and durable, ensuring long-term reliability and minimal maintenance costs.

Versatility: Capable of producing a wide range of bottle shapes and sizes, suitable for various industries including food and beverage, pharmaceuticals, and cosmetics.

Quality Assurance: Comprehensive after-sales support, including installation, commissioning, and training, ensures customers can maximize the extrusion blow molding machine’s potential and maintain high production standards.

Product Description

PRODUCTION CAPACITY :1000 ML

75-25H+S1X2.10BM Blow Molding Machine

PRODUCTION CAPACITY :2000ML-5000ML

SPECIFICATIONS:1.1 HDPE bottle moulding machine extrusion screw diameter:75mm; vies-strip screw 25mm; single layer single diehead;doubel stations; weight:8.5ton(up);

1.2 Siemens plc with 7inch color touch screen adding temperature control & moitoring

1.3 China Taiwan yuken oil valve, manifolds electroplated;

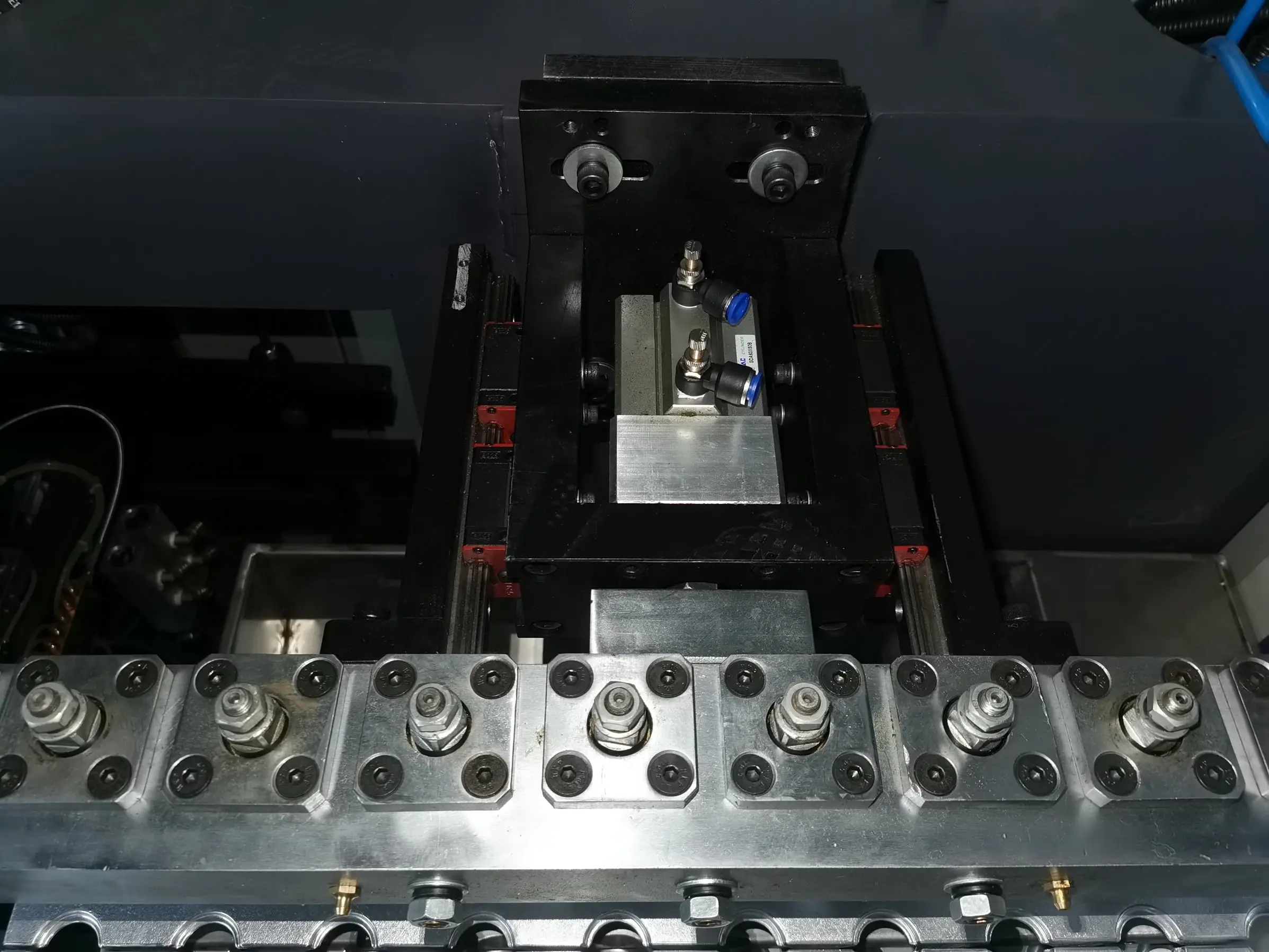

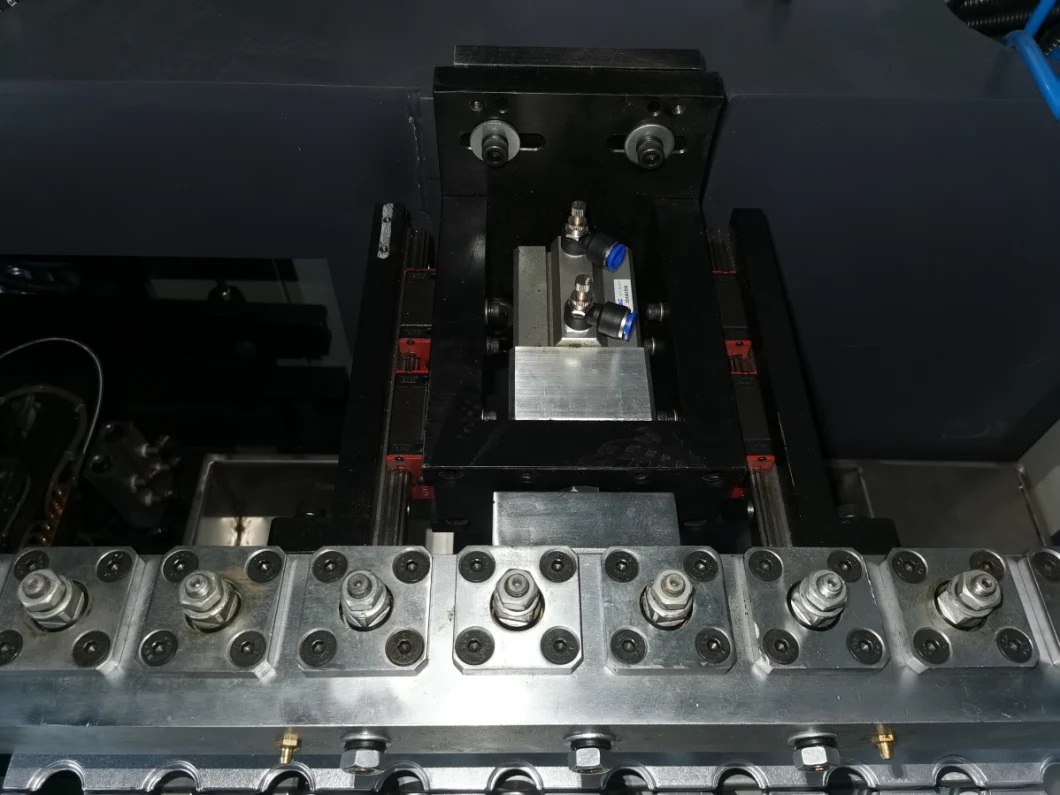

1.4 Independent 100 points thickness precision control system: Japanese yuken servo valve & english tr transducer.

Omron proximity switch

1.5 Japanese spp servo oil pump, eura servo motor; distance deceleration valve. Clamping locked and station moving adopting precition linnear guideway;

1.6 Auto deflasher: Cutting bottle neck and pushing bottom flash; fitting mould for 2 cavities.

1.7 Blow molding machine internal maintainance light system and eletric socket.

specifications

75-25H+S1X2.10BM Blow Moulding Machine

CAVITY DISTANCE:250mm;

PRODUCTION CAPACITY :2000ML-5000ML;

EXTRUCTION SCREW DIAMETER:75mm,

MAX EXTRUSION CAPACITY: 125KG (HDPE5502 CHINA)

VIEW-Strip:25mm;

We have a professtional after-sale service team, before machine arrive, we will give consulting service about the machine place, eletricity, and water prepare works. after machine arrive in customer factory, we also send engineer for installation, and make training for customer's engineer, customer should take charge of the engineer travel cost, board and lodging and labor cost.

Not only blow machine, we also provide turnkey project service of bottle design, bottling equipment line, bottle filling, and packing.

A: yes, the machine is available for 3L-10L water bottle, edible oil bottle, etc

Q11: is the blowing machine full electrical

A: the machine is control by full servo for all units, no need prepare low pressure air for the blowing machine

Q12: is the blowing machine available for different bottle mold

A: yes, the machine is designed with very easy bottle mold change unit, only need 30minutes to change a mold

zhongshan vfine machinery co ltd

zhongshan Chumful machinery co ltd