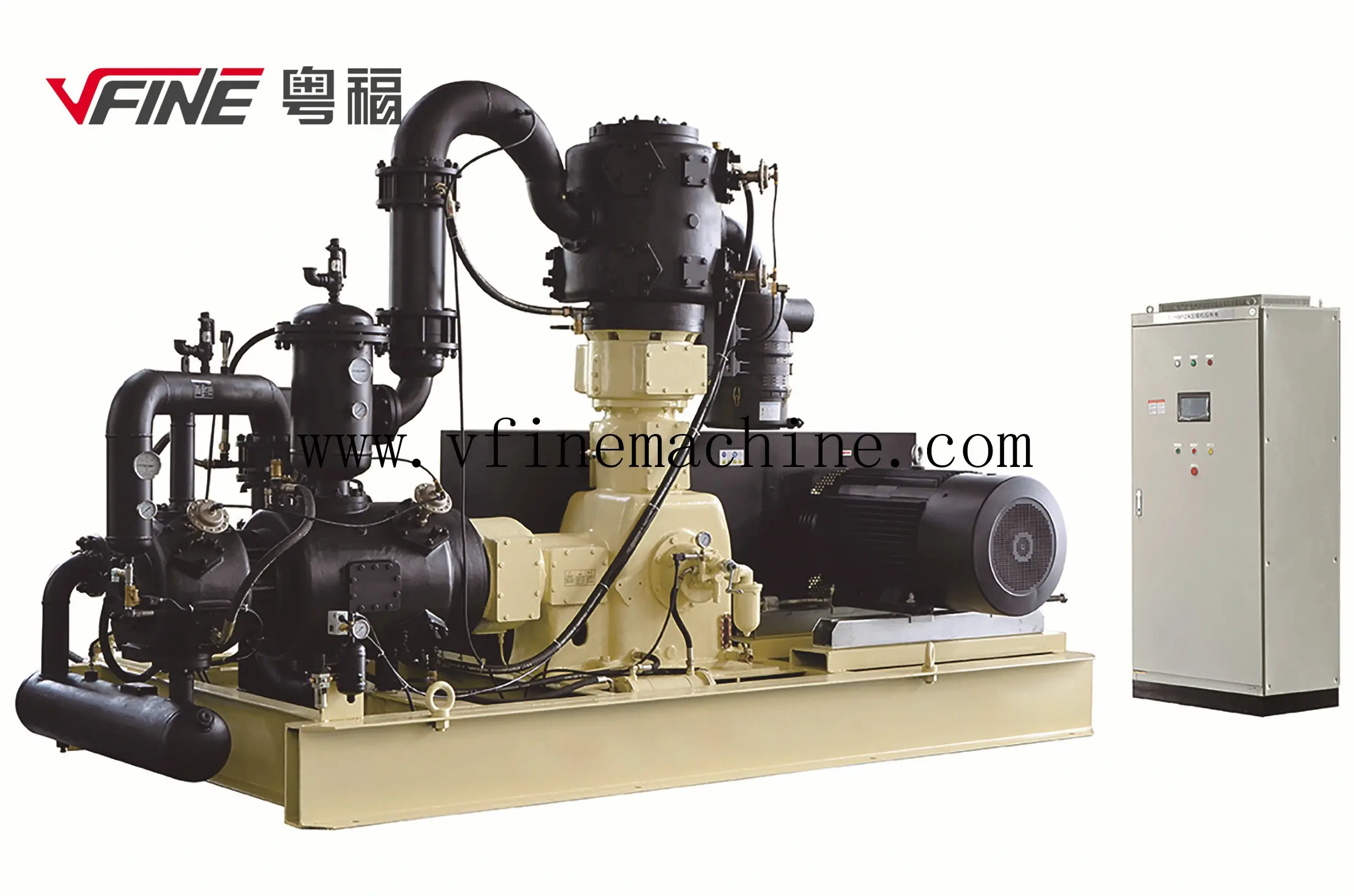

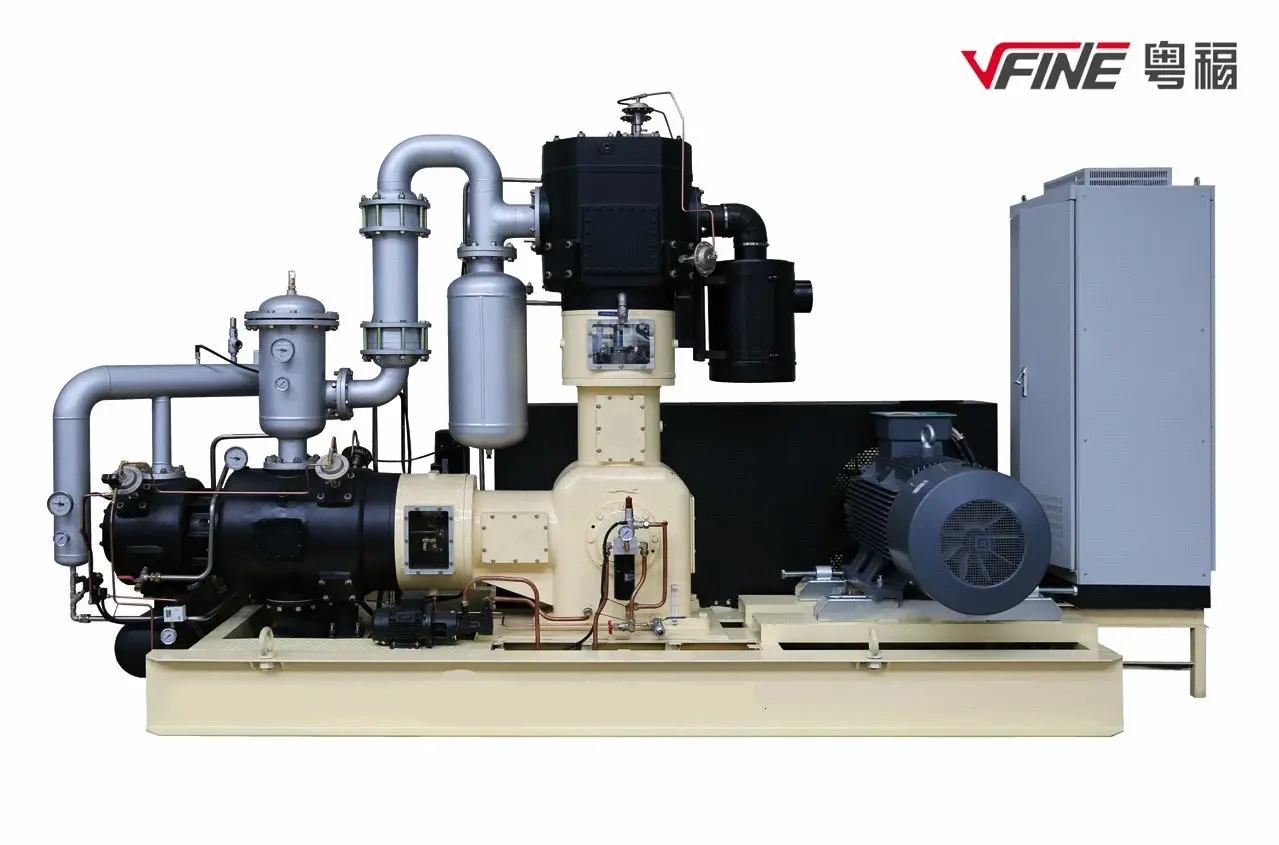

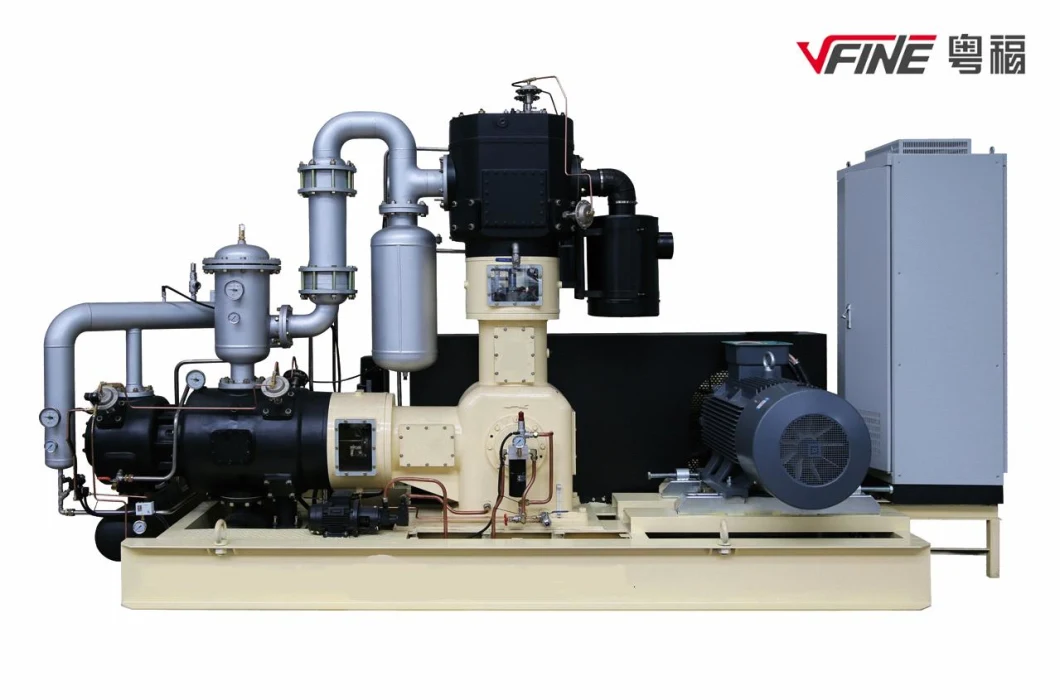

High Pressure Oil Free Air Compressor System - Energy Efficient & Low Maintenance

Product features

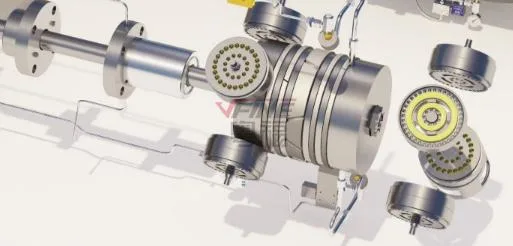

Our High Pressure Oil Free Air Compressor System is designed with energy efficiency and low maintenance in mind. With features like adjustable air capacity, low noise levels, and a water-cooling design, our compressor is perfect for various applications requiring high-quality compressed air. The stainless steel material used in the system ensures durability and protection for industries like food and beverage. Our system also includes easy installation and maintenance, making it a reliable choice for air compressor companies looking for top-notch performance.

Company profile

At our company, we are dedicated to providing high-quality, energy-efficient, and low-maintenance air compressor systems. Our focus on creating innovative solutions for our customers' needs drives us to constantly improve our products and adapt to changing industry trends. With a strong commitment to sustainability and reliability, our high-pressure oil-free air compressor systems are built to last, offering long-term value and efficiency for your business. Trust in our expertise and experience in the industry to provide you with the best solutions for your compressed air needs. Choose us for top-of-the-line products and unparalleled customer service.

Enterprise core strength

Our company has a long-standing reputation for providing high-quality, energy-efficient, and low maintenance high-pressure oil-free air compressor systems. With a focus on innovation and customer satisfaction, we strive to deliver top-of-the-line products designed to meet the demanding needs of various industries. Our commitment to excellence and reliability ensures that our customers receive a superior product that enhances productivity and efficiency. By choosing our high-pressure oil-free air compressor system, customers can rest assured that they are investing in a durable and cost-effective solution that will exceed their expectations. Trust our company to deliver cutting-edge technology and exceptional performance for all your compressed air needs.

We feature a broad range of hi-quality High Pressure Oil Free Air Compressor Unit System for Pet Water Tank Beverage Medicine Cosmetic Chemical Bottle Blowing Making Manufacturing for peolpe of all age group. Our professional engineers applied technology to product development.The product can be used in a wide range of applications like Compressor Unit requiring very high quality. For product inquiries, technical support, and other questions, you can reach us in any way stated on our 'Contact Us' page.

| Model NO. | 25m3/min/40kg | Application | Intermediate Back Pressure Type |

| Performance | Low Noise, Variable Frequency | Mute | Mute |

| Lubrication Style | Oil-free | Drive Mode | Electric |

| Configuration | Portable | Power Source | AC Power |

| Material | Stainless Steel | Transport Package | Wooden Package |

| Trademark | vfine | Origin | China |

| HS Code | 8414809090 | Production Capacity | 15 |

Product Description

| ITEM | GOODS DESCRIPTION | QTY | TECHNICAL SPECIFICAITON AND DESCRIPTION |

| 1 | Oil free air compressor | 2 | L type oil free air compressor capacity:12M3/min, air pressure:4.0Mpa |

| 2 | Air tank C-2.0/40 | 1 | It is the storage of compressed air, buffering and temperature cooling(when the air stored in the air tank, the air temperature will cool down, it can also partly separate the air dirt and water) |

| 3 | Pre-filter | 1 | Protect of air dryer, capacity 24m3/min, pressure:4.0Mpa. |

| 4 | Air dryer | 1 | Clear all the water in air,capacity 24m3/min ,pressure: 4.0Mpa.meantime, the oil dirt would be partly separate alone with the water. |

| 5 | Post-filter | 1 | Post filter Capacity: 24m3/min,pressure:4.0Mpa. |

| 6 | Precise filter | 1 | Precise filter Capacity 24m3/min,pressure:4.0Mpa. |

| 7 | Caton filter | 1 | Caton filter Capacity 24m3/min,pressure:4.0Mpa. |

| 8 | Combine pallet for item 3-7 | 1 | Item 3-7 are combine in one pallet, installation is quite simple. This unit have automatic water drain valve. |

specifications

model:HLW-25/40

| item | description | |

| model | HLW-12/40 | |

| type | Water-cooling L type piston 3cylinder 3stage compressor | |

| Compress material | air | |

| capacity | m3/min | 12(input air Capacity) |

| pressure | Mpa | 0.1(A) |

| temperature | ºC | ≤40 |

| pressure | Mpa | 4.0 |

| Installation power | KW | 132 |

| noise | dB(A) | 75 |

| voltage | V/Ph/Hz | 380/3/50 |

| Cooling type | Water cooling | |

| Output Air temperature | ºC | ≤ 150(before cooling) ≤ 60(after cooling) |

| Lubricating oil temperature | ºC | ≤ 60 |

| Lubricating way | gear pump pressuring lubrication | |

| Motor protecting level | IP54 | |

| Impact level | mm | ≤28 |

| Crankshaft rotate speed | r/min | 580 |

| Output outlet diameter | 1.5" | |

| Cooling outlet diameter | 1.5" | |

| Inlet water temperature | ºC | 10-32 |

| Output water temperate | ºC | 15-37 |

| Cooling tower | T/h | 30 |

| Machine size | mm | 4050*1750*2380 |

| weight | kg | 6000 |

1,high pressure air tank

model:2.0m3/4.0Mpa

specifications

| capacity | M3/min | 2.0 | ||

| Max pressure | MPA | 4.0 | ||

| Max inlet air temperature | ºC | <100 | ||

| Max environment temperature | ºC | 38 | ||

| Safety valve,gauge,manual water drain. | TANK Certificate | |||

| SIZE | mm | Inner diameter 800*2319 height | ||

| Function of air tank | It is the storage of compressed air, buffering and temperature cooling(when the air stored in the air tank, the air temperature will cool down, it can also partly separate the air dirt and water) | |||

repressure air treatment system

| capacity | 25Nm3/min | |

| Work specifications | Max input air pressure | 4.0Mpa |

| Input air temperature | ≤80ºC | |

| Pressure dew point | 10-15ºC | |

| Working environment temperature | <46ºC | |

| refrigerant | R22 | |

| power | 4.8kw | |

| Cooling way | Air cooling | |

| Compressor | japan | panisonic |

| Power | voltage | 3phase/380V/50Hz |

| Piping | Inlet diameter | DN80 |

2, filter

Pre-filter

| capacity | 25 m3/min |

| Max air pressure | 4.0Mpa |

| Input air temperature | ≤60ºC |

| Dirt rate | normal |

| Oil rate | normal |

| Work temperature | ≤45ºC |

| structure | Filter element |

| Inlet and outlet diameter | DN80 |

| installataion | Inside room |

(2)post filter

| capacity | 25 m3/min |

| Max air pressure | 4.0Mpa |

| Input air temperature | ≤60ºC |

| Dirt rate | normal |

| Oil rate | normal |

| Work temperature | ≤45ºC |

| structure | Filter element |

| Inlet and outlet diameter | DN80 |

| installataion | Inside room |

(3)precise filter

| capacity | 25 m3/min |

| Max air pressure | 4.0Mpa |

| Input air temperature | ≤60ºC |

| Dirt rate | normal |

| Oil rate | normal |

| Work temperature | ≤45ºC |

| structure | Filter element |

| Inlet and outlet diameter | DN80 |

| installataion | Inside room |

(4)carton filter

| capacity | 25 m3/min |

| Max air pressure | 4.0Mpa |

| Input air temperature | ≤60ºC |

| Dirt rate | normal |

| Oil rate | normal |

| Work temperature | ≤45ºC |

| structure | Filter element |

| Inlet and outlet diameter | DN80 |

| installataion | Inside room |

We have a professional after-sale service team, before the machine arrive, we will give consulting service about the machine's place, electricity, and water preparation works. after the machine arrives in the customer's factory, we also send the engineer for installation and make training for the customer's engineer, customer should take charge of the engineer's travel cost, board and lodging , and labor cost.

| item | description |

| Save energy | The water-cooling type oil free air compressor is the most functional, energy-saving compressor, the compressor air capacity can auto-adjust range from 1/4 to full loading. Eg: the 12m3/min is adjusted from 3-12m3, the starting current is 15A, it can save 80%-90% energy. After start, the half- frequency idle, can save 50% energy. When the air reachesl the setting air pressure, the machine is in half- frequency idle model, if the machine is in long time idle model, the machine will stop automatic, save 100% energy. |

| Low rotating speed | The rotating speed is only 390-580, ensure the run stale with very small vibration, low abrasion, low noise, It can keep the life of piston ring and valve longer. |

Simplify the structure, and make the maintenance easier | In the first stage, the operation is drop from up to down by free fall, this can save the energy cost, normally the first stage would consume 45% energy of the complete machine, free fall design can reduce the abrasion of the piston ring, lengthen the spare part life time. |

| The machine is design in L structure, the third stage is without piston filler, it is very helpful for high pressure air sea, and very convenient for maintenance | |

| The system equipment is combined in one pallet, simplify the installation, no need special foundation. | |

| The air compressor is in three stages compress, ensure stable running, easy maintenance and low down the maintenance cost. | |

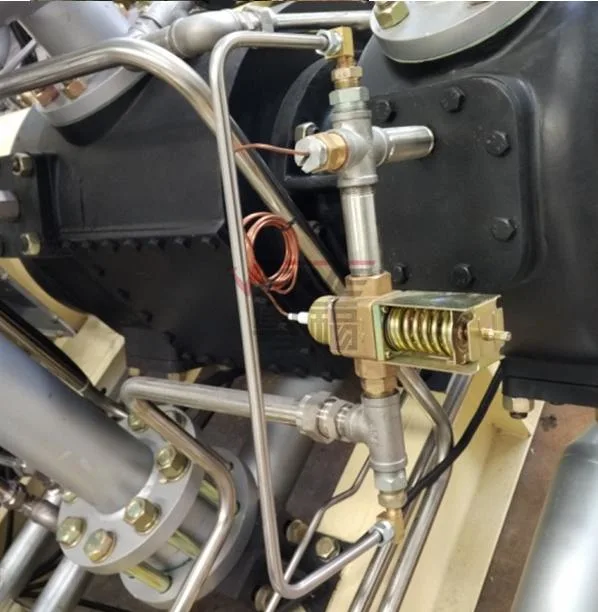

| material | The whole piping inside the compressor system is with stainless steel in S304.No rust powder inside the whole system, that is great protect for the food and beverage industry. |

| Temperature control | The first stage compress air in cool temperature, it is cooled by 3-4kg cool water. We need to stable the second stage cylinder temperature, to make sure the cylinder temperature is same with the air, to protect the forming of condensate. The third stage temperature is with oil cooling, so lengthen the piston life time. |

After checking, within the quality guarantee time, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

After quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems

Training: customers can send technician to vfine factory for 7-10 days training by buyers own charge. Vfine(Chumful) engineer will also make training for customer techinician during installation time.

Zhongshan Vfine MACHINERY CO LTD

Zhongshan CHUMFUL MACHINERY CO LTD