High Pressure Oil-Free Air Compressor System for PET Bottle Industrial Use

Product features

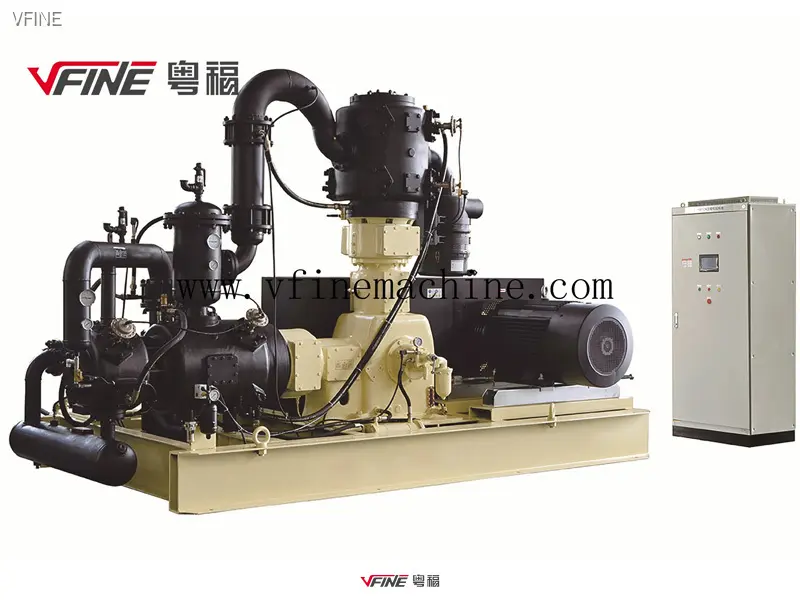

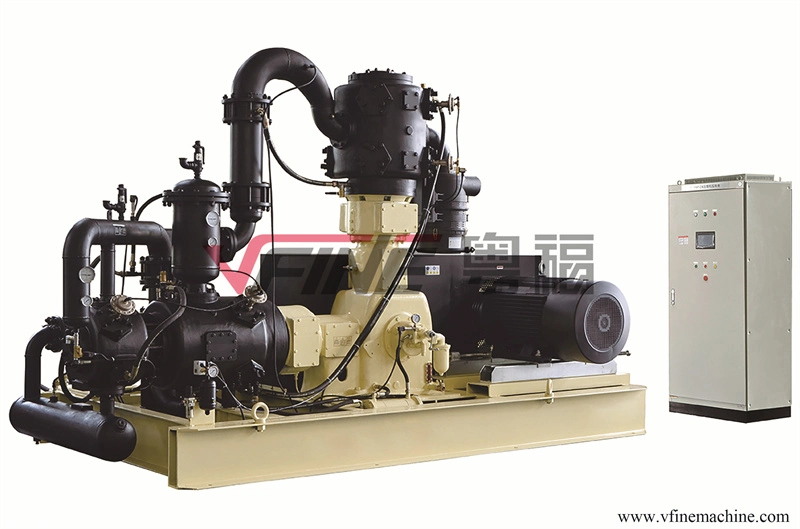

The High Pressure Oil-Free Air Compressor System for PET Bottle Industrial Use by Zhongshan Vfine Machinery Co., Ltd provides a reliable and efficient solution for blowing molding machines. This system includes air compressor, high pressure air tank, air dryer, pre-filter, post-filter, precise filter, and carbon filter, ensuring clean and high-quality compressed air for production lines. With professional installation instructions and a dedicated after-sales service team, customers can trust in the expertise and technology offered by Vfine Machinery Co., Ltd to optimize their industrial processes.

Company profile

At our company, we are committed to providing high-quality solutions for industrial use, such as our High Pressure Oil-Free Air Compressor System designed specifically for PET bottle manufacturing. With a focus on reliability and efficiency, our product delivers clean and high-pressure air, ensuring optimal performance in your production process. As a trusted supplier in the industry, we prioritize customer satisfaction and strive to meet the unique needs of our clients. With our innovative technology and dedication to excellence, you can trust us to provide the best solution for your industrial air compressor needs.

Why choose us

Our company specializes in providing high-quality and reliable High Pressure Oil-Free Air Compressor Systems for PET Bottle industrial use. With years of experience in the industry, we understand the importance of efficiency and precision in the production process. Our systems are designed to meet the specific needs of PET bottle manufacturers, delivering clean and dry compressed air that is crucial for maintaining the quality of the final product. Trust in our expertise and dedication to providing top-notch solutions for your industrial operations. Choose our company for your air compressor needs and experience the difference in performance and reliability.

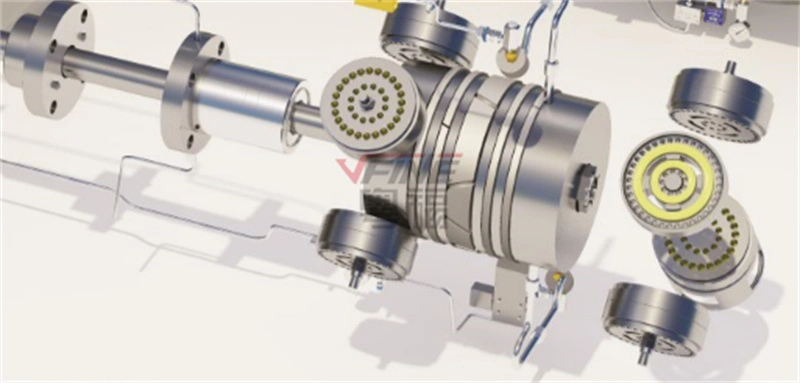

Zhongshan Vfine Machinery Co., Ltd is market-oriented, combined with pioneering and innovative technology research and development capabilities, coupled with elite talents who are familiar with market operation and management, have a keen market sense and rapid market response capabilities. The team uses the most advanced production equipment and independent research and development technology to minimize High Pressure HP Oil Free Oil-Free Air Compressor System for Pet Bottle Oil Less Screw Piston Booster Portable Laser Industrial development cycle and ensure the high quality and strong reliability of the product. Our expertise and technologies enable tailor-made solutions for every customer.

| Model NO. | 10cbm | Cooling System | Water Cooling |

| Power Source | AC Power | Cylinder Position | Horizontal |

| Structure Type | Closed Type | Installation Type | Stationary Type |

| Type | Twin-Screw Compressor | Transport Package | Wooden Box |

| Specification | 3package | Trademark | vfine |

| Origin | China | HS Code | 8414100090 |

| Production Capacity | 100sets/Year | Package size per unit product | 320.00cm * 100.00cm * 130.00cm |

| Gross weight per unit product | 3500.000kg |

Product Description

| item | Description and suggestion |

| Air compressor Air pressure:4.0Mpa | Produce the high pressure air |

| tank Air pressure:4.0Mpa | Storage of the high pressure air, also as the buffer to cool the hot air; the water and dirt would be left in tank, so that to reduce load of air treatment system. |

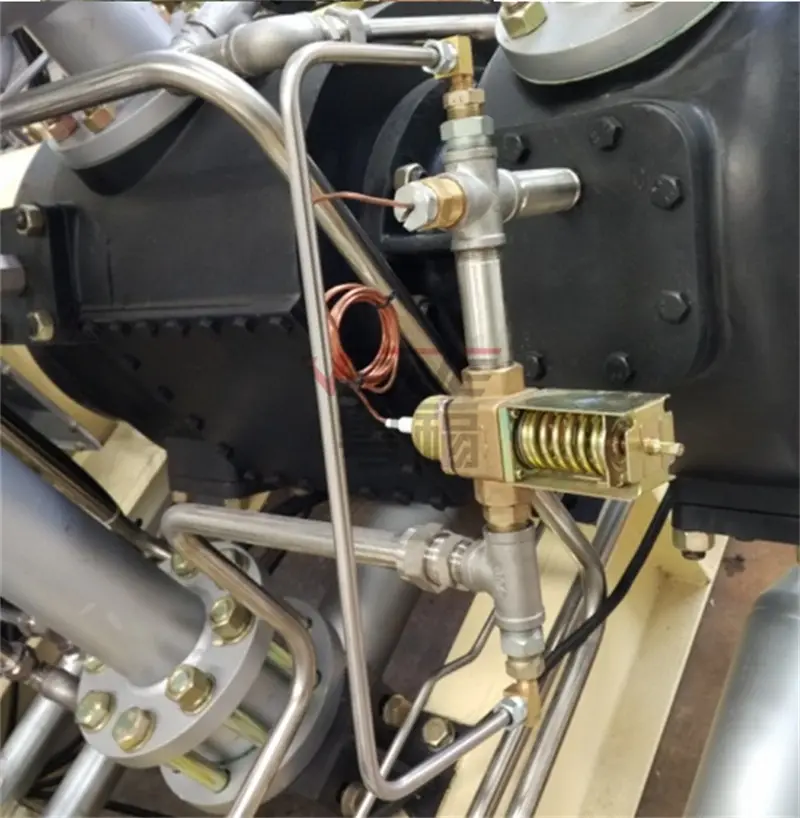

| High pressure air dryer Air pressure:4.0Mpa | The oil and water within the compress air would be cooled to liquid status, the solid dirt together with the cold liquid will be exhausted out from the automatic drain, then the clean air can be provide to the production line. |

| Pre-filter Air pressure:4.0Mpa solid≤3 um Oil left≤5ppm | Clean the big solid dirt in the compress air. |

| Post filter Air pressure:4.0Mpa solid≤1 um Oil left≤1ppm | Clean the medium size solid dirt in the compress air |

| Precise filter Air pressure:4.0Mpa solid≤0.01 um Oil left≤0.01ppm | Clean all the solid dirt in the compress air |

| Carton filter Air pressure:4.0Mpa solid≤0.01 um Oil left≤0.003ppm | Clean the smell and dirt in the compress air |

We have a professtional after-sale service team, before machine arrive, we will give consulting service about the machine place, eletricity, and water prepare works. after machine arrive in customer factory, we also send engineer for installation, and make training for customer's engineer, customer should take charge of the engineer travel cost, board and lodging and labor cost.

Not only blow machine, we also provide turnkey project service of pet bottle design, PET bottling equipment line, PET bottle filling, and packing.

A: yes, the machine is available for 3L-10L water bottle, edible oil bottle, etc

Q11: is the blowing machine full electrical

A: the machine is control by full servo for all units, no need prepare low pressure air for the blowing machine

Q12: is the blowing machine available for different bottle mold

A: yes, the machine is designed with very easy bottle mold change unit, only need 30minutes to change a mold

zhongshan vfine machinery co ltd

zhongshan Chumful machinery co ltd