bottle blowing machine

machine high light

1. Fully automatic, full-servo, high-speed, high quality bottle blow molding machine,

2. the production capacity is at least 8500bph

3. Smart mold design, can quickly change the mold within 30 minutes.

4. Intelligent design, pull rod equipment, heating parameter setting, blowing parameter and speed setting can all be completed on the operation screen.

5. Durable machine, low energy cost, Low maintenance cost

6. Application scope: PET bottle for water, Juice, soda, Ice tea, CSD, beer, wine, milk, consident, cooking oil, soy sauce, etc.

| Model | YF-6E |

| Max bottle volumn | 750ml |

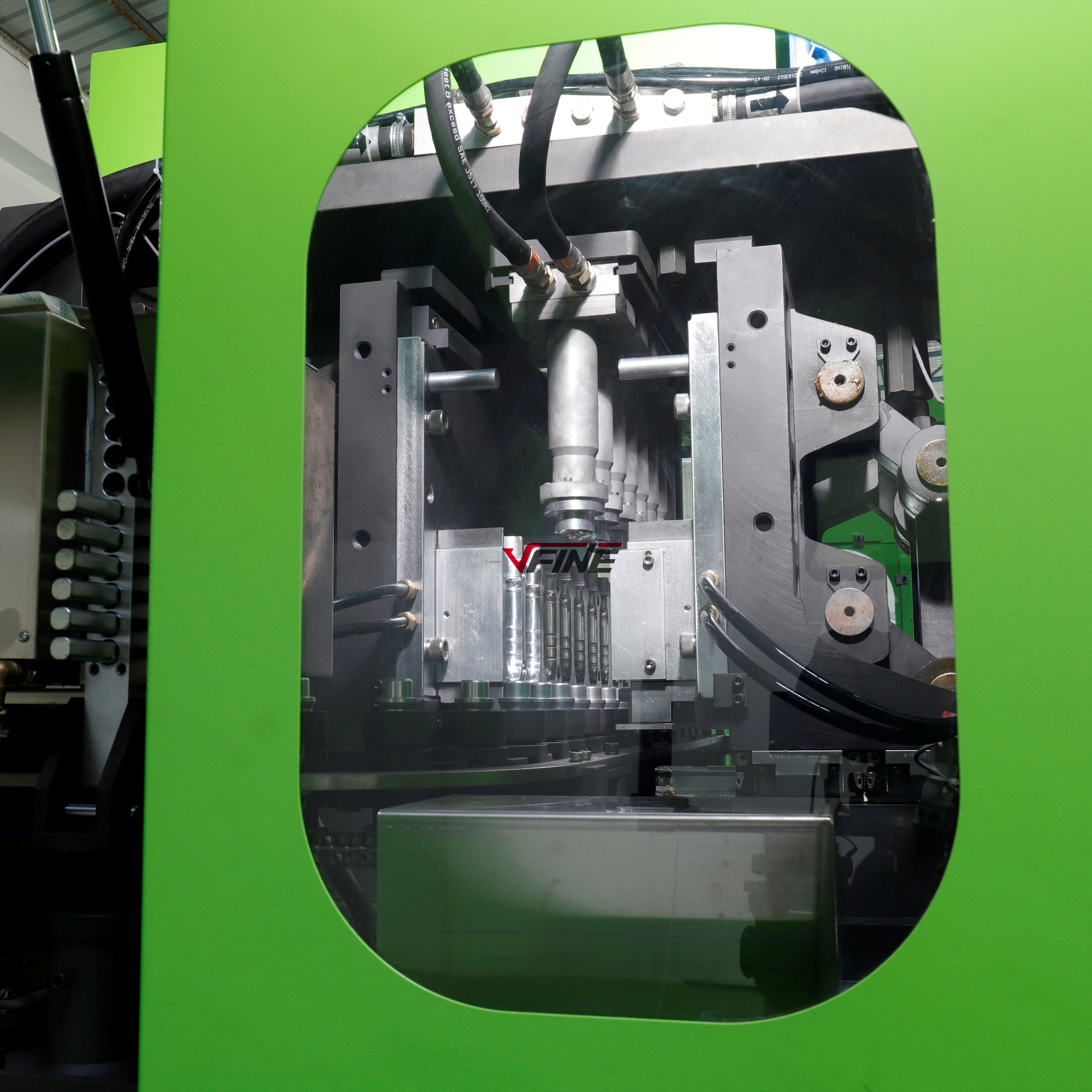

| Cavity number | 6 |

| Output | 8500-9000bph |

| Machine Size | 4000*2000*2500mm |

| Machine weight | 6500kg |

6-cavity, linear stretch blowing molding machine

Output: 8500-9000bph

Max. Volume: 0.75L

(2)application scope

Suitable for producing PET water bottle, carbonate bottle, middle temperature filling bottle etc.

|

|

|

|

|

Features of main blowing machine:

A. Stable performance with advanced PLC.

B. Conveying preforms automatically with conveyor.

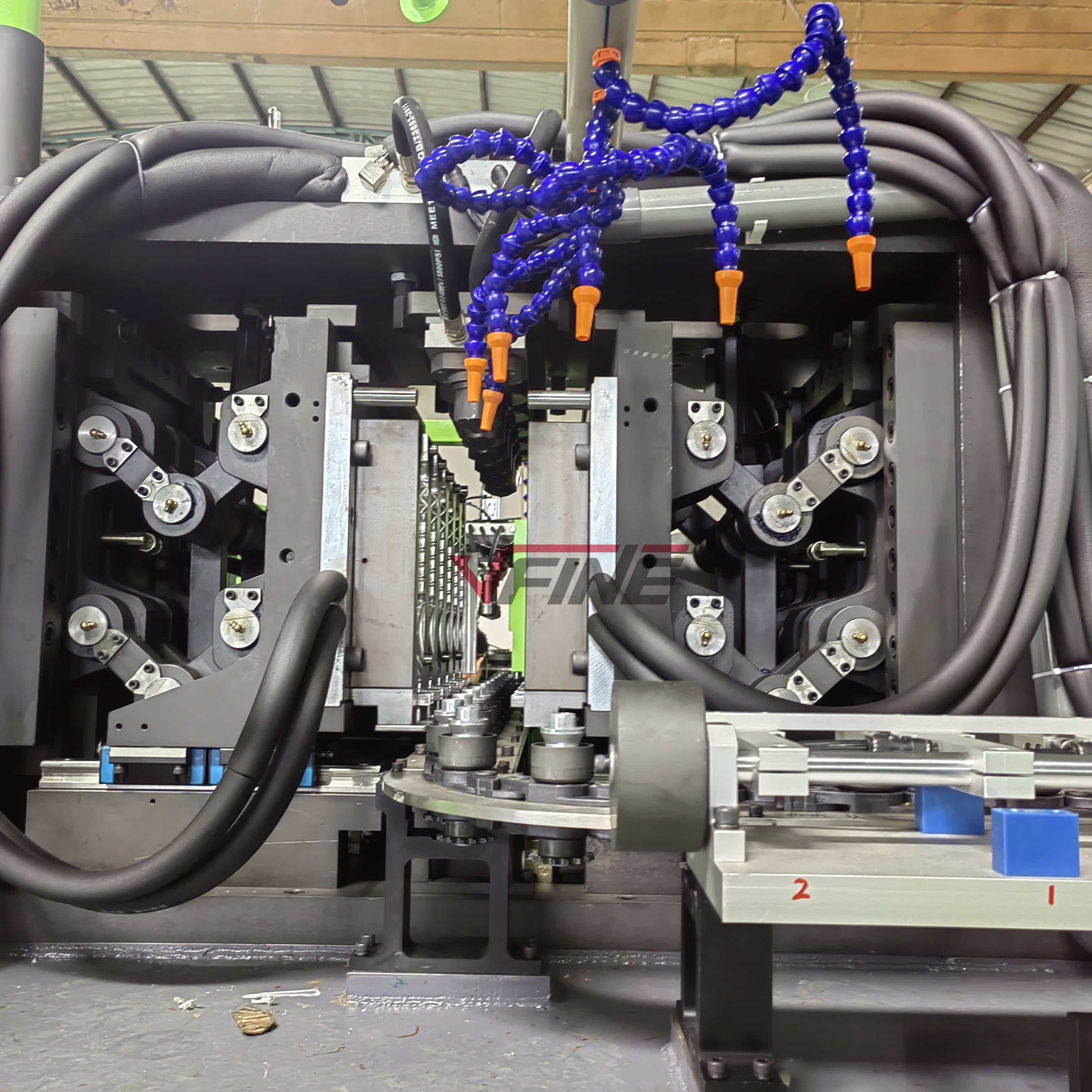

C. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheater.

D. High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

E. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

F. No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

G. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

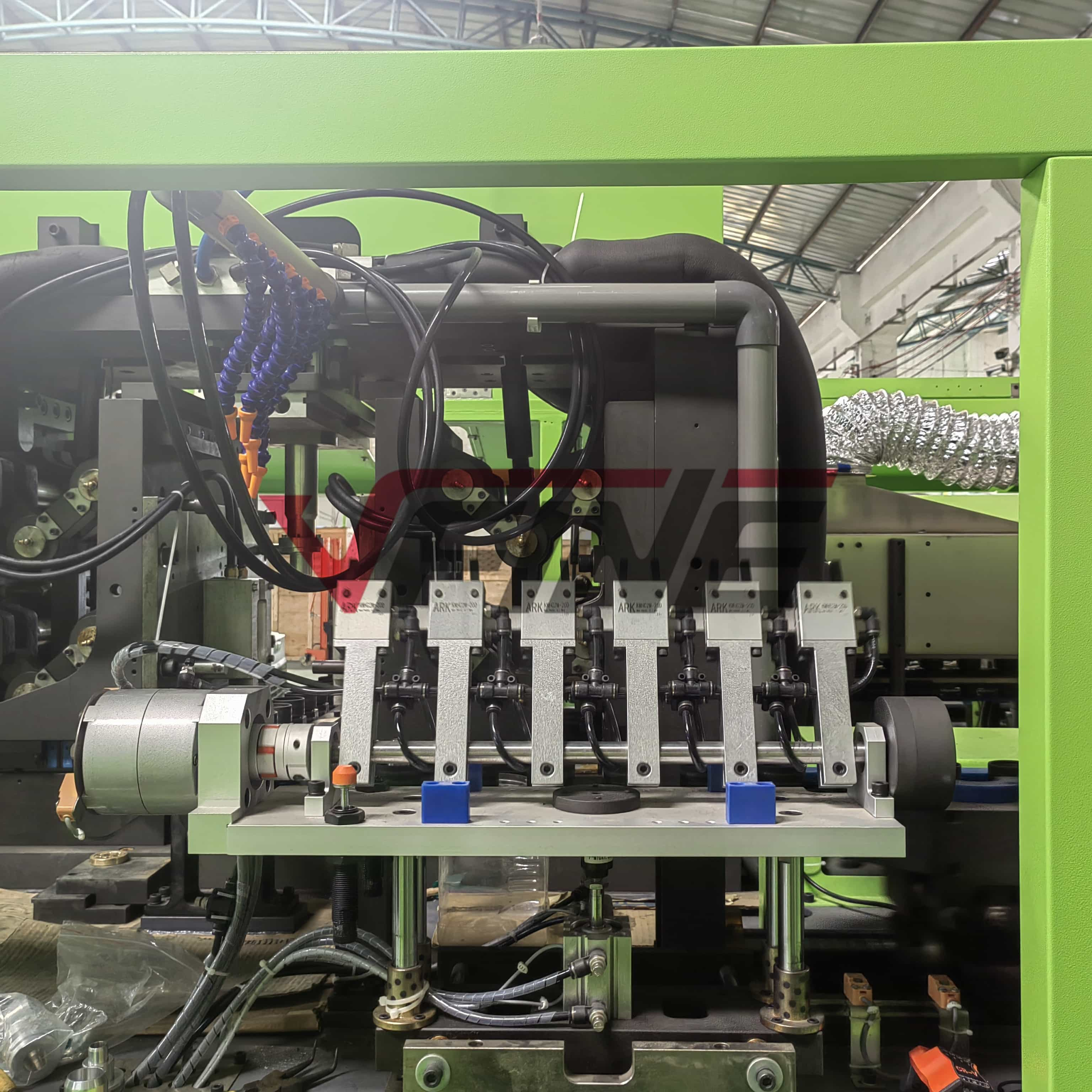

H. Strong clamping force with high pressure and double crank links to lock the mold.

I. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

J. Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

K. Contamination is avoided for the bottle body.

L. Ideal effect of the chilling with the chilling system.

M. Easy installation and starting

|

|

|

Factory Pictures

Zhongshan chumful machinery co ltd is the one branch of Zhongshan Vfine machinery co ltd, which is a professional manufacturer of PET bottle blowing machines, that integrates the R&D, production, and sales. Since the development and design of the first generation linear automatic stretch blow molding machine, Vfine's technical team has focused in the PET market for 20 years. We've successfully supplied machines to many world-famous brands. Not only the bottle blowing machine,Vfine(CHUMFUL) also provide the turnkey plant service for all customers, we can offer from A to Z solution for all kind of PET bottle production, PET bottle water, and pet bottle beverage.

Company Advantages

Communication:

Good communication with our customers to know the target product details, output demands, confirm the most suitable machine models and provide whole project quotations.

Mould design:

After confirmed the product, our engineers will provide the professional 3D drawing as per your samples, and we can also help you design the bottles as per your own idea or based on our own samples.

Drawing confirmation:

After finalizing the drawings, we will send to you for approval, only after your approval & signature, we will officially start the mould & all project.

Machine&mould production:

After customer confirm and sign the drawing, we will start the production process, from sheet-metal process, CNC fine machining, machine assembly painting, to electrical installing machine & mould testing, product testing.

Testing:

We provide sufficient raw materials foreach customer's project, to makeenough testing in our factory for bothmachine and mouldsIt will 100% guarantee that there is noany problem before delivery tocustomer's factory.

Product inspection:

After mould tested, we will do inspections to dimensions appearance, cap sealing, thickness filling lever, drop testing, leakage testing, screw testing... so on, to ensure the finishing is 100% as per original sample.

Installation and training:

We will send the engineers to customer's factory to test run the machine until it is running in normal state. Customer will bear the round-trip air tickets, accommodation, hotel and technology fee. We will also help customer training their operator how to operation and maintenance machines, make sure they can operate our machine independently.

Packaging&Shipping

Machine are packed with plastic film, auxiliary machines and spare parts are packed with wooden boxes. The loading to containers is done according to weight balance, every package's position is fixed in containers to avoid moving. The photos of whole delivery will be sent to our customers for reference.

|  |  |

|  |  |