High-Quality Mineral Water Filling Machine

Product features

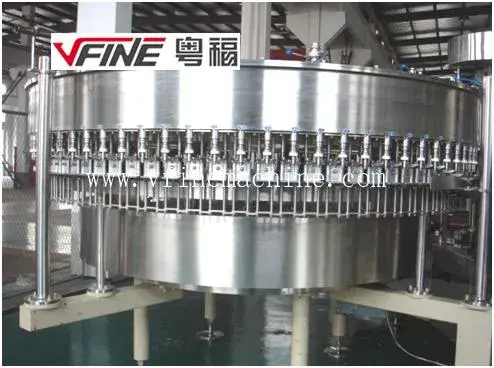

The high-quality mineral water filling machine from Zhongshan Vfine Machinery Co., Ltd features a state-of-the-art design based on advanced technology from Germany and Italy, ensuring precision and efficiency in beverage production, specifically for pure water and mineral water. The machine's innovative features include a unique overturning bottle clamp for hygienic bottle gripping and a high-efficiency atomizing spray nozzle for thorough bottle cleaning. With superior components like stainless steel rotary wheels and German-made filling valves, this machine offers high accuracy, speed, and durability for seamless bottling operations. The comprehensive design includes a rinsing system, filling system, capping system, driven system, feeding system, and electricity controlling system, making it a top choice for businesses in need of reliable and high-performance filling equipment.

We serve

At our company, we pride ourselves on our commitment to serving our customers with the highest-quality mineral water filling machine. Our cutting-edge technology ensures efficient and precise filling, while our durable materials guarantee long-lasting performance. We serve our clients by providing a reliable, user-friendly product that exceeds expectations in both functionality and durability. Additionally, our exceptional customer service team is always available to assist with any inquiries or concerns. Trust us to deliver a product that not only meets but surpasses your needs, making us your go-to choice for all your mineral water filling machine requirements.

Why choose us

At our company, we are dedicated to serving our customers with the highest quality mineral water filling machine. We prioritize efficiency, precision, and reliability in all aspects of our product design and manufacturing process. Our machine is equipped with state-of-the-art technology to ensure seamless operation and consistent production of high-quality mineral water. In addition to our commitment to excellence, we also serve our customers with exceptional customer service and support. We are always ready to address any questions or concerns, and strive to exceed expectations in every interaction. Choose our mineral water filling machine and experience the difference in quality and service.

Since our inception, Zhongshan Vfine Machinery Co., Ltd has been engaged in the R&D of products to keep us ahead of other competitors in the industry. The key to Automatic Capsule Filling Filler Bottling Pure Water Beverage Soda Soft Energy Drink Bottle Liquid Mineral Production Line Equipment Machine Machines Price competitiveness is innovation. In the future, the company will expand business further.

| Customized | Customized | Voltage | 380V |

| Composition | Filling Machine | Processing Material | Natural Ingredients |

| Process | Thermal Processing | Transport Package | Wooden Package |

| Specification | 3*3*2.3 | Trademark | vfine |

| Origin | China Guangzhou | HS Code | 8422301090 |

| Production Capacity | 100sets/Year | Package size per unit product | 420.00cm * 230.00cm * 230.00cm |

| Gross weight per unit product | 4000.000kg |

Product Description

General description

XGF Series is designed and manufactured based on the latest technology from Germany and Italy, for the demand of technical requirement of beverage production, as pure water and mineral water.

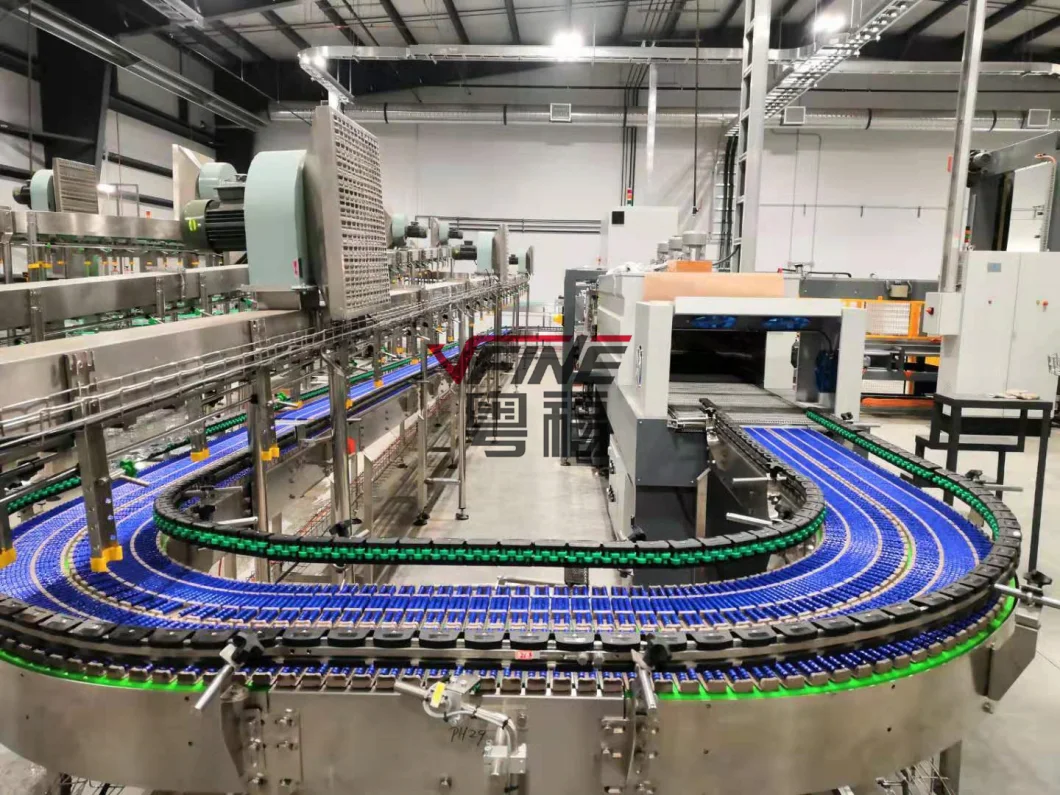

The filling mono-bloc works as follows: Bottles are fed from conveyor chain into the filling machine mono-bloc via star wheel. Bottle clamp installed on the rotary wheel of the rinse will grip bottle mouth and make a 180° turn along a guide track to face the bottle mouth downward. In designated section of the rinse, rinsing water will jet out from special nozzles to flush bottle inside wall. After rinsing and dripping, bottles gripped by bottle clamp will make another 180° turn along a guide track to resume bottle mouth facing up position. Clean bottles are discharged out of the rinse by a star wheel to feed the filler. After entering the filler, bottles are retained by neck supporting carrier plates, which are actuated by bottle carrier mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals. After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process. Bottle carrier mechanism is lowered by a cam to disengage filled bottles with filling valves. Then bottles are transferred into the capper by a neck handling star wheel. Anti-rotation blades on capping heads will seize the bottleneck to prevent it from rotation and hold it in a upright position. The twist-on capping head will make revolving and rotating movement along with the machine to finish the complete capping process of cap picking, placing, twisting, and disengaging under the control of a cam. A discharge star wheel discharges finished bottles onto discharge conveyor belt to be conveyed out of the filling mono-bloc.

1)Rinsing system :Rinsing gripper dial, separating water dial, water trough

2)Filling system :Liquid tank, filling valves, controlling rings, upgrading cylinder

3)Capping system :Screwing capper, cap sorter, falling cap guide

4)Driven system :gear-driven ,main- motor, gear wheel

5)Feeding system :Guide board, star wheel, conveying chains

6)Electricity controlling system:Adjusting speed with frequency conversion, PLC, touch-screen operation

Main features

. Bottle in feed

Bottle in feed by combination of in feed screw and in feed star wheel

Equipped with bottle jam protection device.

The rotary wheel is a fully SS304 stainless steel welded structure.

The machine applies unique overturning bottle clamp, which is an innovation of our company. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp. Made of SS304 stainless steel, this bottle clamp is hygienic and durable.

The high efficiency atomizing spray nozzle installed on bottle clamp incorporating technology from Spaying Systems Co. Ltd., is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

The rinse is driven by driving system positioned inside machine frame via gear transmission.

Made of stainless steel of superior quality.

Equipped with bottle jam protection device.

The filler is designed and manufactured with application of Italy technology, providing hardware guarantee for securing product quality and reducing loss.

Rotary wheel are fully made of stainless steel SS304.

Filling valves are designed and manufactured with German technology, made of SS304, featuring high filling accuracy and high filling speed.

Bottles are raised and lowered by cam controlled lifting cylinder. Valve opening mechanism is actuated by air cylinder.

Hydraulic pump is float-ball controlled.

The filler is driven by driving system positioned inside machine frame via gear transmission.

1) The capper is most precise part in 3 in 1 filling machine, because the quality of machine is important to running credibility and product quality. The sealing machine in our company has strongpoint as follows:

2) The cover track has the device to prevent the reversal cover from passing and pick out the reversal cover. Meanwhile the photoelectric switch can stop the machine automatically when there is no cover on the track, by which it can avoid bottle without cover effectively.

3) It also has the bottle check-up switch. Together with cylinder on the joint of the cover track and cover lift, they can control the cover flow and stop it in case no bottle to reduce the quantity of cover.

4) Highly effective acentric way for cap sorting to reduce the abrasion.

5) It has the check-up device to control the cover lift.

Specification:

| MODEL | XGF24-24-6 |

| LOCATION NUMBER | WASHING 24,FILLING 24,CAPPING 6 |

| Rated capacity | 12000B/H(500ml/PET BOTTLE) |

| Filling method | Gravity |

| Applicable bottle | Diameterφ50-φ108mm,Bottle height 165-335mm |

| Compressed air source | 0.7 MPa |

| Compressed air consumption | 0.8M3/min |

| Washing bottle pressure | 0.2-0.25 MPa |

| Washing bottle water consumption | 1.8ton/hr |

| Rated voltage | 380V |

| Main bottle power | 2.2Kw |

| Machine total power | 5.35Kw |

| Size of the machine | 3700×2150×2450 (L×W×H) |

| Weight | 5000Kg |

We have a professtional after-sale service team, before machine arrive, we will give consulting service about the machine place, eletricity, and water prepare works. after machine arrive in customer factory, we also send engineer for installation, and make training for customer's engineer, customer should take charge of the engineer travel cost, board and lodging and labor cost.

Zhongshan chumful machinery co ltd is the one branch of Zhongshan Vfine machinery co ltd, which is a professional manufacturer of PET bottle blowing machines, that integrates the R&D, production, and sales. We also provide turkey project service of water bottle complete line.Since the development and design of the first generation linear automatic stretch blow molding machine, Vfine's technical team has focused in the PET market for 20 years. We've successfully supplied machines to many world-famous brands.

![Automatic Capsule Filling Filler Bottling Pure Water Beverage Soda Soft Energy Drink Bottle Liquid Mineral Production Line Equipment Machine Machines Price]()

![Automatic Capsule Filling Filler Bottling Pure Water Beverage Soda Soft Energy Drink Bottle Liquid Mineral Production Line Equipment Machine Machines Price]()

Vfine sales consultant

1. We can provide comprehensive and professional Suggestions on equipment selection.

2. Energy consumption calculation and investment income analysis can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product optimization Suggestions.

4. The stretch plastic bottle blow molding machine has remote maintenance function

Advantages of Vfine tech teams

1. Many sets of customized machines in the market enable us to have rich experience across multiple industries.

2. Customize equipment models according to customer product characteristics.

3. Project responsibility system, closed-loop team cooperation between the design team and the process team, adjustment of the team, and joint creation of equipment that users are satisfied with.

4. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry.

5. Undertake a number of large projects, and has a group of senior technical personnel composed of the construction team, can build cable bridge, installation of a complete set of equipment.

Advantages of Vfine Machinery after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment.

5. Free training for customer technician while making installation

6. Special processing equipment to produce after-sales accessories to ensure rapid response to user needs.

PET Bottle complete line water beverage soft drink filling machine machinery filler price made in china

vfine88.en.made-in-china.com

zhongshan Vfine machinery co ltd

Zhongshan Chumful Machinery Co Ltd

Diana Ren

mobile:+8613823903135