Industrial Air Compressor for Laser Machines

Product features

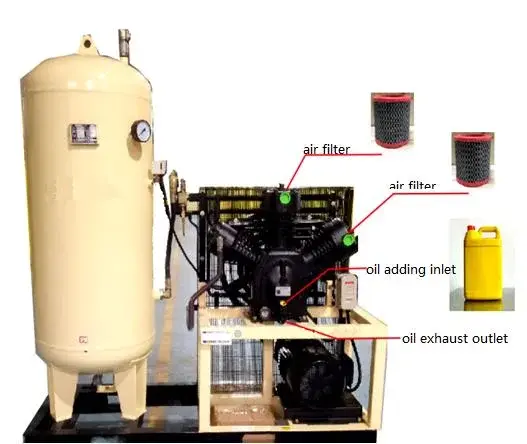

The industrial air compressor for laser machines by Zhongshan Vfine Machinery Co., Ltd. is a cutting-edge product designed to meet the demanding needs of the industry. With a balanced opposed arrangement and open type structure, this compressor delivers high-pressure air efficiently. Featuring multistage compression levels and ammonia refrigerant type, this compressor system ensures optimal performance for 1KW or 2KW laser machines, solving industry pain points with advanced technology.

Company profile

We are a leading manufacturer of industrial air compressors tailored for laser machines. Our company has a solid reputation in providing high-quality and reliable compressor solutions for a wide range of applications. With years of experience in the industry, we understand the unique needs of our customers and strive to deliver products that meet and exceed their expectations. Our team of skilled engineers and technicians work tirelessly to ensure that our compressors are efficient, durable, and cost-effective, providing our customers with the best value for their investment. Choose our industrial air compressors for your laser machines and experience superior performance and reliability.

Enterprise core strength

Our company is a leading provider of industrial air compressors designed specifically for laser machines. With a focus on quality and reliability, we offer a range of high-performance compressors that are essential for the efficient operation of laser equipment. Our commitment to excellence is evident in our products, which are built to last and deliver consistent and powerful air supply. As a trusted supplier to businesses across various industries, we take pride in providing top-notch customer service and technical support. Partner with us for all your industrial air compressor needs and experience the difference our company can make for your business.

It is one of the hot-selling products of Zhongshan Vfine Machinery Co., Ltd. The Catair Air Compressor System Laser Machine Air Supply Ca-11tk Ca 1.2-30h Ca15tk Cat-1.0/30kg launched by the company are made using the company's newly developed advanced technology, which perfectly solves the long-standing pain points of the industry. In the future, Zhongshan Vfine Machinery Co., Ltd will focus on technological innovation, continuously improve service quality and develop better products, and is committed to providing customers with products and services that exceed expectations.

| Model NO. | CA-11TK | Cooling System | Air Cooling |

| Cylinder Arrangement | Balanced Opposed Arrangement | Cylinder Position | Angular |

| Structure Type | Open Type | Compress Level | Multistage |

| Refrigerant Type | Ammonia | Product | Air Compressor System |

| Transport Package | Wooden Package | Specification | 2T |

| Trademark | vfine | Origin | China |

| HS Code | 8414100090 | Production Capacity | 100sets/Year |

Product Description

CA 1.2-30H CAT-1.0/30KG

CA-11TK CA15TK

Specifications

machine:air compressor

2stage piston type air cooled compressor

High pressure part(source air)

Specification

| power | HP | 11KW |

| capacity | m3/min | 1.08 |

| Inlet air temp. | ºC | ≤35 |

| Exhaust air temp. | ºC | ≤60 (after cooling) |

| Full load air pressure | Mpa | 1.55 |

| voltage | V/Hz/Ph | 380/50/3 |

| Cooling way | Air type | |

| motor | IP54 | |

| Insulation level | F Level | |

| Motor quantity | set | 1 |

| Machine size | Mm | 1730*780*1850 |

High pressure part(source air)

| item | Description and suggestion |

| Air compressor Air pressure:1.55Mpa | Produce the high pressure air |

| tank Air pressure:1.6 Mpa | Storage of the high pressure air, also as the buffer to cool the hot air; the water and dirt would be left in tank, so that to reduce load of air treatment system. |

| High pressure air dryer Air pressure:1.6Mpa | The oil and water within the compress air would be cooled to liquid status, the solid dirt together with the cold liquid will be exhausted out from the automatic drain, then the clean air can be provide to the production line. |

| Pre-filter Air pressure:1.6Mpa solid≤3 um Oil left≤5ppm | Clean the big solid dirt in the compress air. |

| Post filter Air pressure:1.6Mpa solid≤1 um Oil left≤1ppm | Clean the medium size solid dirt in the compress air |

| Precise filter Air pressure:1.6Mpa solid≤0.01 um Oil left≤0.01ppm | Clean all the solid dirt in the compress air |

Specifications

machine:air compressor

Model:CA-11TK

Specification

| power | HP | 11KW |

| capacity | m3/min | 1.08 |

| Inlet air temp. | ºC | ≤35 |

| Exhaust air temp. | ºC | ≤60 (after cooling) |

| Full load air pressure | Mpa | 1.55 |

| voltage | V/Hz/Ph | 380/50/3 |

| Cooling way | Air type | |

| motor | IP54 | |

| Insulation level | F Level | |

| Motor quantity | set | 1 |

| Machine size | Mm | 1730*780*1850 |

Tank specifications

| capacity | M3/min | 0.4 |

| Max. air pressure | Mpa | 1.6 |

| Max air temp. inlet | ºC | <100 |

| Size L*W*H | Mm | |

| Max workshop temp. | ºC | 38 |

Air treatment system

1, dryer

Model: 2m3/1.6Mpa

specification

| capacity | 2Nm3/min | |

| Max inlet pressure | 1.6Mpa | |

| Inlet temp. | ≤80ºC | |

| Dew point | 10-15ºC | |

| Environment temp. | <46ºC | |

| Recycle water | ||

| coolant | R22 | |

| power | 0.8kw | |

| Cooling type | Air type | |

| Inlet Water pressure | ||

| Inlet water | ||

| Coolant compressor | Japan | Panasonic |

| drain | vavle | 3pc Netherlands valve |

| power | 220V/50Hz | |

Pre-filter

| capacity | 2.0m3/min |

| Max inlet pressure | 1.6MPa |

| Inlet temp. | ≤60ºC |

| Environment temp. | ≤45ºC |

| Filter precision | ≤3μm |

| Oil in Outlet air | 5ppm (w) |

| Pressure drop | dry drop ≤0.007MPa, wet drop ≤ 0.014MPa |

| Filter element | 6000-8000hour |

| structure | Filter element |

| connector | DN20 threaded fittings |

| drain | Drain includes, exhaust automaticly |

(2)post-filter

| capacity | 2.0m3/min |

| Max inlet pressure | 1.6MPa |

| Inlet temp. | ≤60ºC |

| Environment temp. | ≤45ºC |

| Filter precision | ≤1μm |

| Oil in Outlet air | 1ppm (w) |

| Pressure drop | dry drop ≤0.007MPa,wet drop ≤ 0.014MPa |

| Filter element | 6000-8000h |

| structure | Filter element |

| drain | Drain includes, exhaust automaticly |

| connector | DN20 threaded fittings |

(3)precise filter

| capacity | 2.0m3/min |

| Max inlet pressure | 1.6MPa |

| Inlet temp. | ≤60ºC |

| Environment temp. | ≤45ºC |

| Filter precision | ≤0.01μm |

| Oil in Outlet air | 0.01ppm (w) |

| Pressure drop | dry drop ≤0.007MPa,wet drop ≤ 0.014MPa |

| Filter element | 6000-8000h |

| structure | Filter element |

| drain | Drain includes, exhaust automaticly |

| connector | DN20 threaded fittings |

Compressor, motor, V-belt with cover, exhaust valve, manual water drain, gauge