VFINE - Pet Bottle Container Tank Water Minural Pure Bottling Stretch Blow Blowing Making Moulding Molding Manufacturing Machine Molder Moulder Manufacturers Price mineral water / beverage bottle blow molding machine

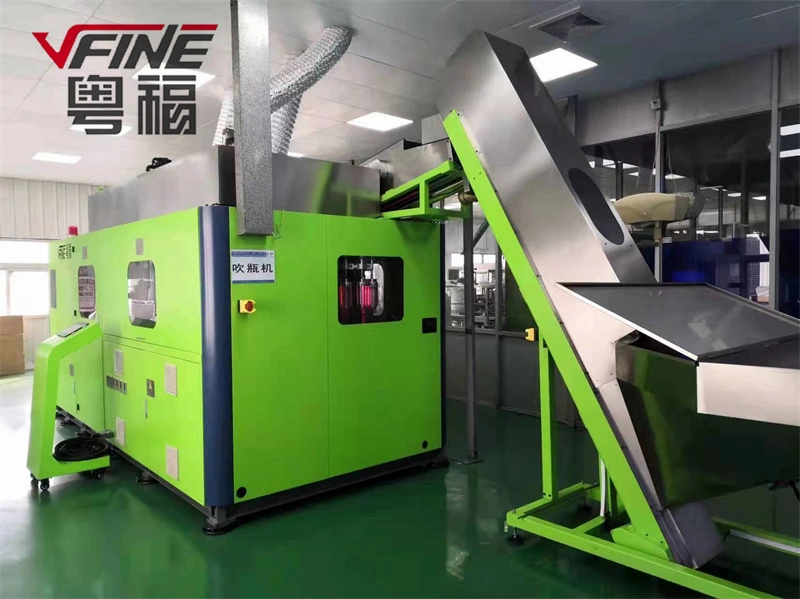

Zhongshan Vfine Machinery Co., Ltd still remembered the time when we successfully developed the new product - Pet Bottle Container Tank Water Minural Pure Bottling Stretch Blow Blowing Making Moulding Molding Manufacturing Machine Molder Moulder Manufacturers Price. The product is absolutely new and has something different in it. Based on Pet Bottle Container Tank Water Minural Pure Bottling Stretch Blow Blowing Making Moulding Molding Manufacturing Machine Molder Moulder Manufacturers Price properties, we have selected technology to manufacture the product after conducting multiple tests and experiments.Our product is qualified for being used in the application field(s) of mineral water / beverage bottle blow molding machine. Zhongshan Vfine Machinery Co., Ltd are determined that we will invest more in the improvement of R&D strength and gather more talents in the industry, both of which can make great contributions to the long-term development of our company.

| Model NO. | YF-L8LE | Making Method of Parison | Stretch Blow |

| Automation | Automatic | Computerized | Computerized |

| Certification | CE, ISO9001:2008 | After-sales Service | Includes |

| Product | Bottle Making Machine | Item | Bottle Making Machine Price |

| Item 3 | Pet Bottle Machinery | Item 4 | Pet Bottle Machinery Price |

| Transport Package | Wooden | Specification | 7m*2m*2.5m(l*w*h) |

| Trademark | vfine | Origin | China |

| HS Code | 8477109000 | Production Capacity | 50-100set/Year |

| Package size per unit product | 600.00cm * 200.00cm * 250.00cm | Gross weight per unit product | 6000.000kg |

Product Description

model: YF-L10E

the machine is with full servo, intensively heating, it intergrate the advantage of PET linear blow molding machine and rotary blowing machine. high efficience, high quality, smart design for worker's operation, and durable.

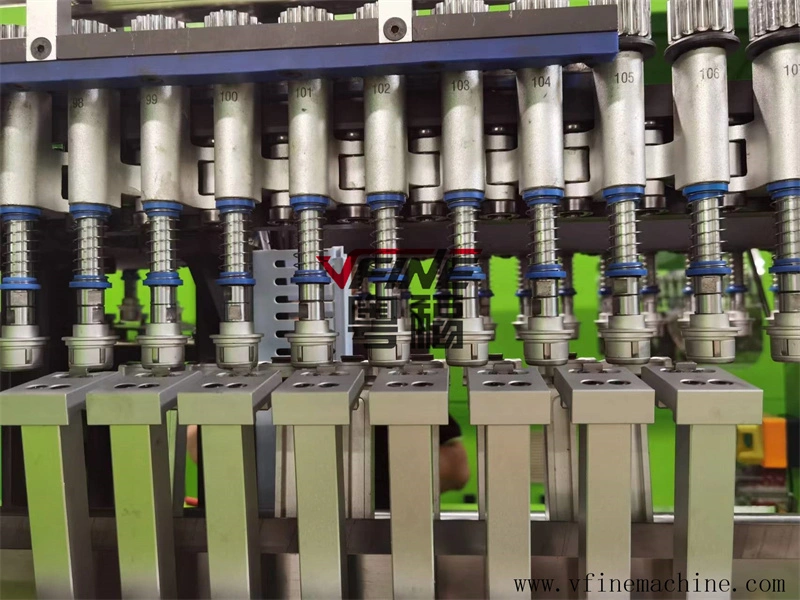

10-cavity, linear stretch blowing molding machine

Output: 18000bph

Max. Volume: 0.6L

(2)application scope

Suitable for producing PET water bottle, carbonate bottle, middle temperature filling bottle etc.

L-series Vfine blowing machine features

- save energy :

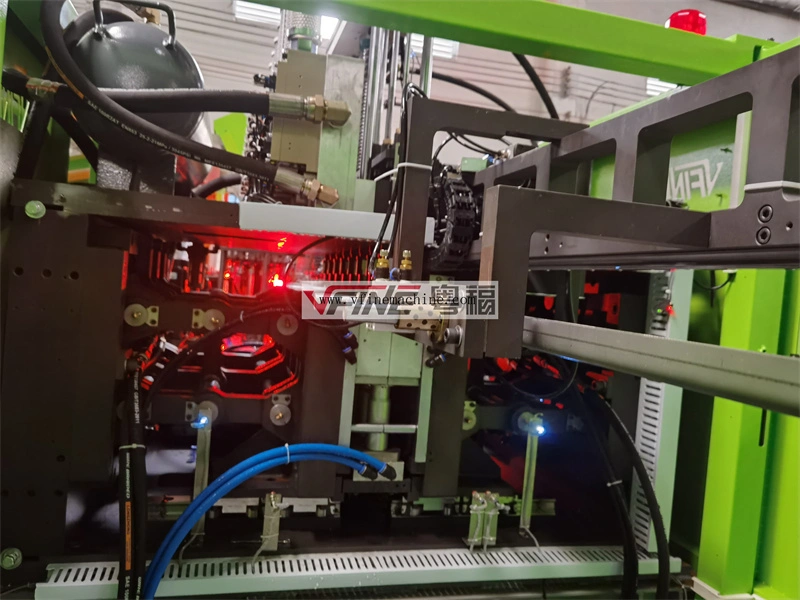

The preform heating and blowing are on separated section, so that it can save the waiting time of each unit. The preforms are heated intensively, as the rotary machine heating type, improve the heating efficiency. Meanwhile, the high pressure air can saved by air recycling system, for the pre-blow or low pressure air supply, save energy. - Save space:

The infeeding system is inside the machine, the heating structure save the preform pitch distance, save the space. - high efficiency:

We improve about 20% output, in the situation of low down the machine energy consumption, improve the overall energy utilization. - Infeeding system:

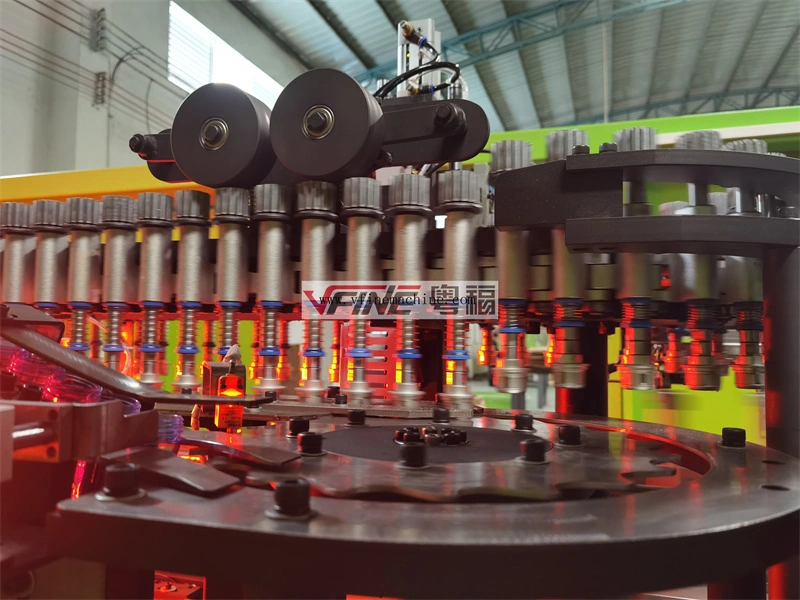

The infeeding system is in single channel with less sensors for better infeeding. - Heating system:

Preforms are heated intensively, the cooling device and the cross ventilation protect the preform neck from out of shape, improve the energy utilization, and heating efficiency. - Transfer unit: The variable pitch device is controlled by servo for stable and accurate transferring.

- Clamping unit: The clamping unit is controlled by servo motor to ensure the synchronization, stable running and precise location.

- High pressure air recycle system: The high pressure air recycle system save the high pressure to the tank, reduce the noise and save energy lost.

(4) Vfine blowing machine YF-L10E specifications

| MODEL | YF-L10E |

| Max Bottle Volumn | 600ml |

| Cavity number | 10 |

| output | 18000BPH |

| Machine size | 6700*2000*2500 |

| Machine weight | 9000kg |

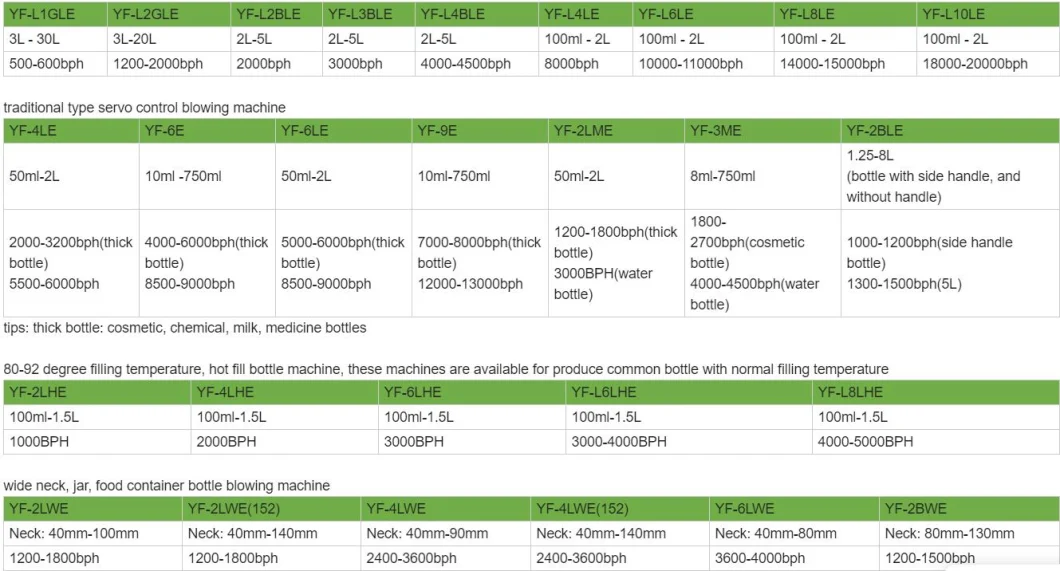

VFINE MACHINERY PRODUCT LIST SHORT VIEW

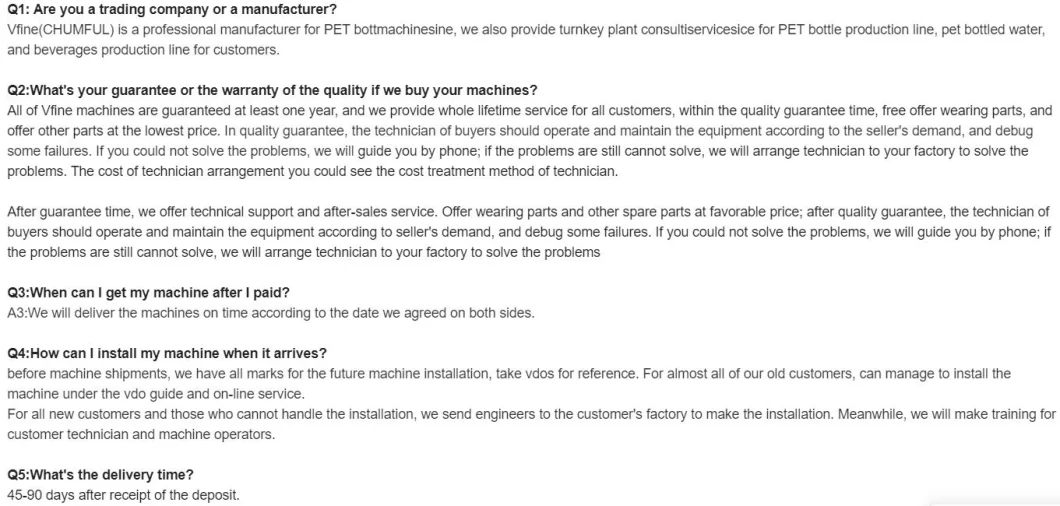

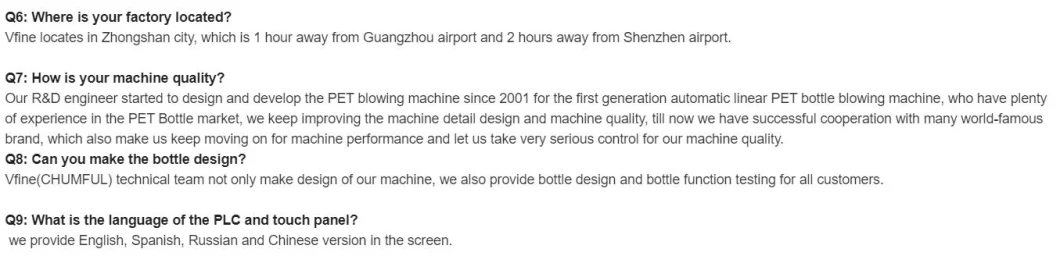

We have a professtional after-sale service team, before machine arrive, we will give consulting service about the machine place, eletricity, and water prepare works. after machine arrive in customer factory, we also send engineer for installation, and make training for customer's engineer, customer should take charge of the engineer travel cost, board and lodging and labor cost.

Not only blow machine, we also provide turnkey project service of pet bottle design, PET bottling equipment line, PET bottle filling, and packing.

zhongshan vfine machinery co ltd

zhongshan Chumful machinery co ltd