VFINE - Pet Mineral Water Bottle Tank Container Stretch Blow Blowing Molding Making Moulding Manufacturing Forming Blowe

The technologies are applied to the manufacturing process, some of which contribute to the high efficiency of Pet Mineral Water Bottle Tank Container Stretch Blow Blowing Molding Making Moulding Manufacturing Forming Blower Machine Machinery Machines Molder System manufacturing and others ensure the stable and durable performance of the product.At present, the product is widely used in the field(s) of Bottle Blowing Machine with its multi-functional characteristics.

With years of development, VFINE occupies an important position in the Bottle Blowing Machine industry now. We are always in strict accordance with the international quality standards and quality management system, totally ensuring the product quality. The product is endowed with stable and multi-functional performance. It is mainly used in the application field(s) of Bottle Blowing Machine. So, shake hands with us, expand your business, and increase your clientele.

| Model NO. | YF-9E | After-sales Service | Includes |

| Raw Material | Pet | Making Method of Parison | Stretch Blow |

| Automation | Automatic | Computerized | Computerized |

| Certification | CE | Transport Package | Film with Wooden Pallet |

| Specification | 5400*2150*2500 | Trademark | VFINE |

| Origin | China | HS Code | 8477900000 |

| Production Capacity | 150set/Year | Package size per unit product | 500.00cm * 200.00cm * 250.00cm |

| Gross weight per unit product | 6000.000kg |

Product Description

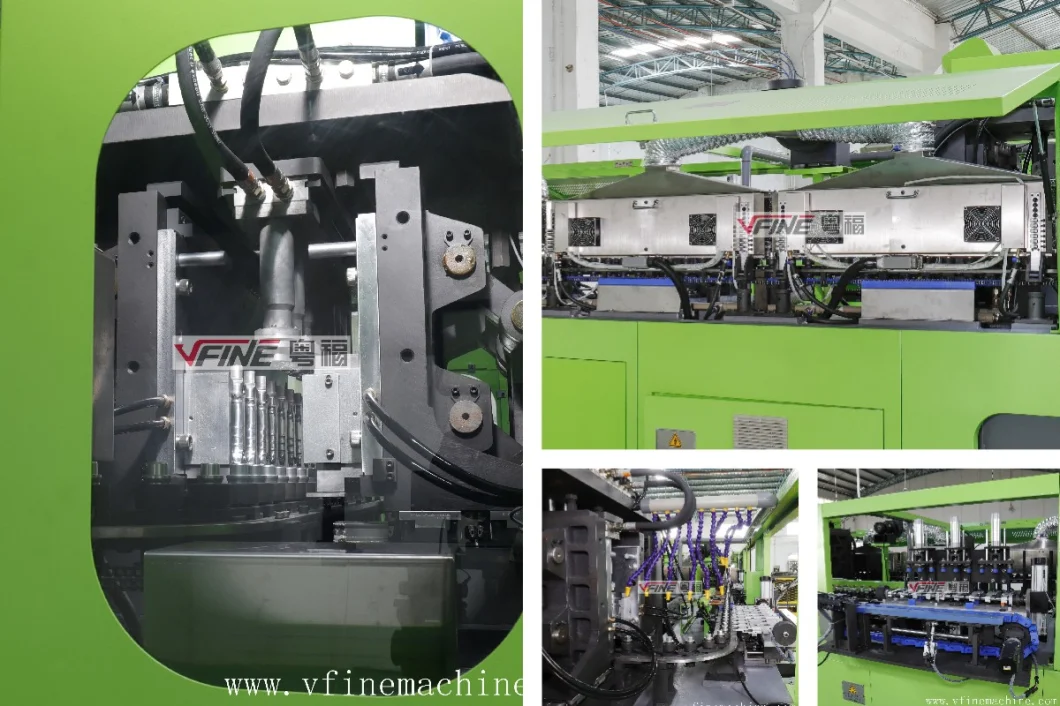

Vfine plastic bottle making Machine full automatic, full servo system

Application scope:

Full automatic blow molding machine is suitable for producing PETplastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle cooking oil bottle, chemical product container, cosmetics, wide-mouth bottle and hot fill bottle etc.

Features of main blowing machine:

1). Stable performance with advanced PLC.

2). Automatic preform conveyer to save human cost.

3). Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4). High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

5). High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6). Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

7). Strong clamping force with high pressure and double crank links to lock the mould.

8). Two ways of operating: automatic and manual.

9). Low cost,high efficiency,easy operation and maintenance etc, profited from the fully automatic technological process.

10). Ideal cooling system make the finished bottles without any flaws.

1.1 New Auto Preform Unscrambler System.

*Adopts one-way preform-feeding structure and preform-separating by servo motor structure which solve the preform block and abrasion problem.

*There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

1.2 New Heating System.

*Perfect heating system design decrease power consumption.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted from screen.

*Cycling water-cooling system keeps the oven temperature constantly.

1.3 The Application Of Servo System On Main Transmission.

The transmission adopts servomotor for positioning that can orientate the preform-heating base quickly, accurately and steadily when the machine starts and running.

1.4 Servo Technology Innovation On Clamping System & Stretching.

*Adopts servo motor to drive the two cranks to control the clamping system which can shorten the mold-clamping time and improve productivity, and also solve the swelling mold and big joint line problem with the effect of pressurize plate.

* Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

1.5 Easy To Change Bottle Shape.

*Drawer type mold structure design is easy for mold changing. Within 30minutes can change a mold on the condition of same bottleneck diameter.

1.6 Intelligent Human-Machine Interface.

*Human-machine interface control, easy operate and monitor.

*Live production information supervise, auto record production data everyday

*Failure warning and troubleshooting.

Item | YF-9E |

Cavity Number | 9 |

Machine output | 12000-13000bph |

Max. volume | 0.75L |

Bottle mouth maximum diameter | 18-38mm |

Bottle maximum diameter | 70mm |

Bottle maximum height | 260mm |

total power/ Installation power | 76 |

Actual power consumption | 40-45kw |

operating pressure | 7kg |

Low pressure air consumption | 1500L/min |

High pressure air pressure | 25-35kg/cm2 |

Higher pressure air consumption | 10000 Ltr/min |

Chilling water pressure | 2-6 kg/cm2 |

Temperature range | 10-12ºC |

Consumption | 54000kcal/hr |

Chilling water flow rate | 180L/min |

Size of the machine(L*W*H) | 5.5x2.15x2.5 |

Weight of the machine | 8ton |

Machine details

| 1) Oil-free preform transferring unit, no neet to concern about the preform polluted in transferring unit.

|

2) World famous brand Germany origin components for whole air system; World famous brand servo system, and electrical system.

|

|

| 3) High quality machine frame and main plates, 15years lifetime.

|

4) Slight and silent clamping unit, ensure nice working environment for operators

|

|

| 5) +/-3% heating output difference only for the heating oven, ensure the stable preform heating for stable product quality.

|

6) Single line preform infeeding unit, no need concern about the preform jam. |

|

Zhongshan Chumful Machinery CO Ltd

Zhongshan Vfine machinery Co ltd