VFINE - Pet Plastic Water Bottle Blow Blowing Molding Molder Molders Making Moulding Stretch Blower Machine Price Manufa

Our engineers and technicians have deep insight into the new technological developments. So far, we have been adopting the upgraded technologies maturel It is popular in the application field(s) of Bottle Blowing Machine.

Pet Plastic Water Bottle Blow Blowing Molding Molder Molders Making Moulding Stretch Blower Machine Price Manufacturers companies spend so much time coming up with various products to reach diverse consumer needs. Innovation ability is the key to the core competitiveness of products. In this technology-driven society, 2017 focus on improving R&D strength and keep developing new technologies so as to increase our competitiveness in the industry. We aim to become one of the leading enterprises in the market.

| Model NO. | YF-9E | Product | Moulding Machine |

| Item | Pet Bottle Moulding Machine | Raw Material | Pet |

| Making Method of Parison | Stretch Blow | Automation | Automatic |

| Computerized | Computerized | Certification | CE, ISO9001:2008, GMP |

| Transport Package | Wooden Package | Specification | 5*2*2.5m(L*W*H) |

| Trademark | vfine | Origin | China |

| HS Code | 8477109000 | Production Capacity | 100set/Year |

| Package size per unit product | 550.00cm * 220.00cm * 250.00cm | Gross weight per unit product | 7000.000kg |

Product Description

moulding machine for PET bottle 9000bph

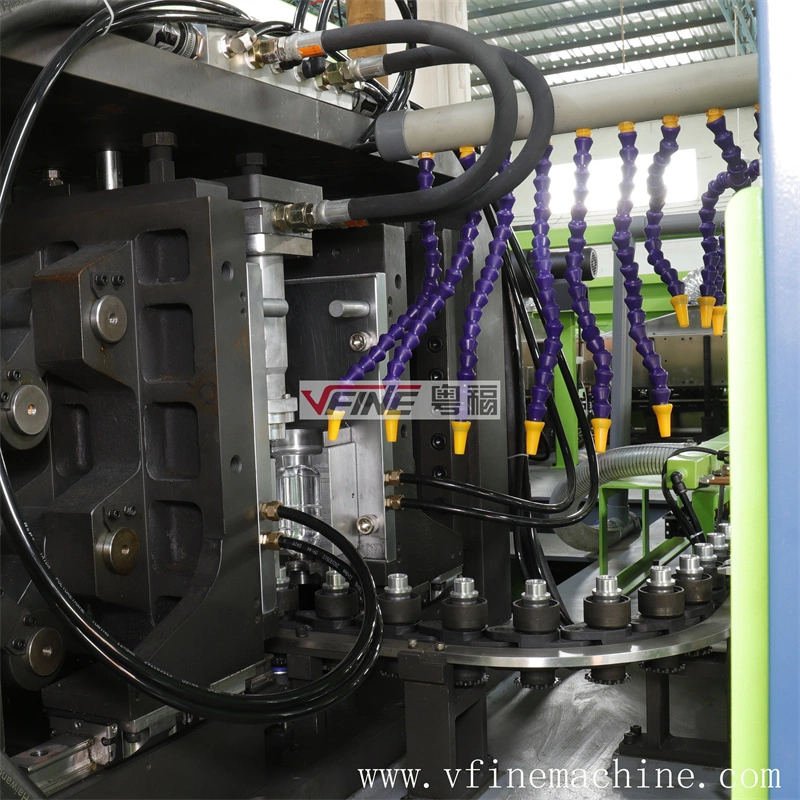

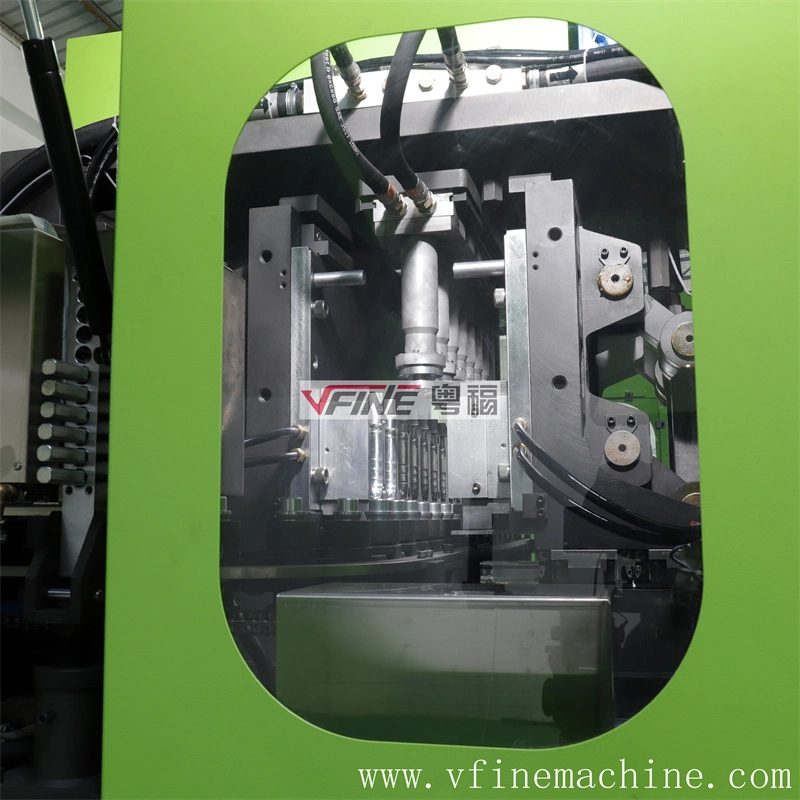

(1)Vfine blowing machine YF-6LE

6-cavity, linear stretch blowing molding machine

Output: 8500-9000bph

Max. Volume: 2L

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Warranty of core components: 1 Year

Application: Water, Medical, chemical, shampoo, cooking oil, juice, milk, wine bottles

Plastic Processed: PET

Place of Origin: Zhongshan, China

operating: servo motor control for clamping, preform transferring, stretching

oil-free preform transferring

Linear structure, modular design, easy maintenance;

Full servo system

Full electrical blowing machine, servo motor together with high pressure air compensation device, ensure stable running;

Easy change mould

Drawer mould-fix structure,only need 30minutes for change mould of different bottle shape with the same neck size;

Save energy

The machine includes high pressure air recycle system, which can save about 25% high pressure air, reduce energy lost;

High efficiency

The machine output of each cavity is 1400~1500bph.

The machine includes auto-lubricating system; ensure the machine running stable and efficiency.

Safety

The machine includes safety protecting device, ensure production security.

bottle blow molding machine

blowing machine YF-6LE specifications

| MODEL | YF-6LE |

| Max Bottle Volumn | 2000ml |

| Cavity number | 6 cavity |

| output | 8500-9000BPH |

| bottle type | all kinds of PET bottle, size from 10ml-2000ml |

| blowing air pressure | 35kg |

| operating air consumption | no need |

| Machine size | 5000*2000*2500mm |

| Machine weight | 8000kg |

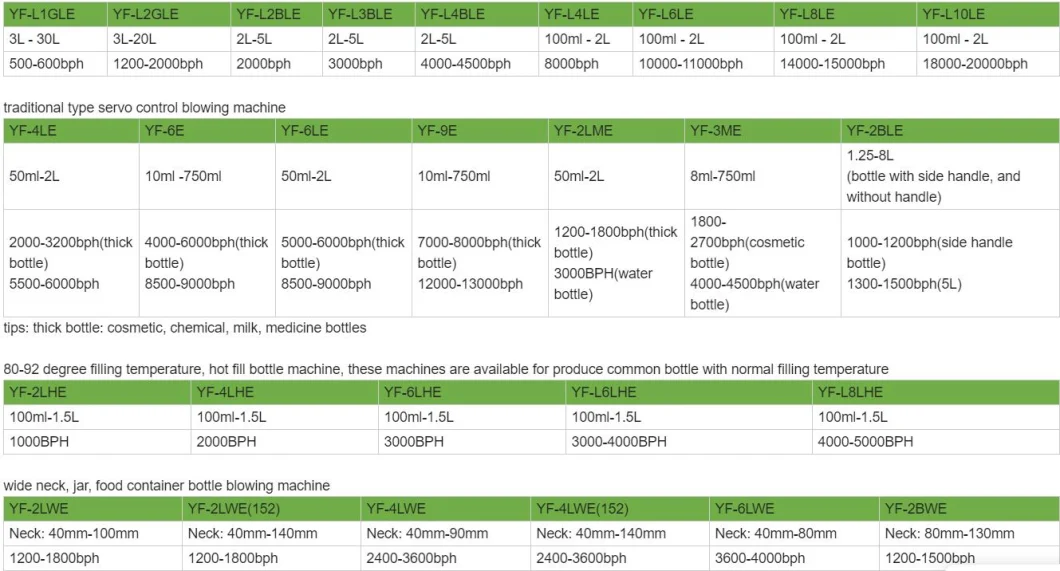

vfine bottle blow molding machine models

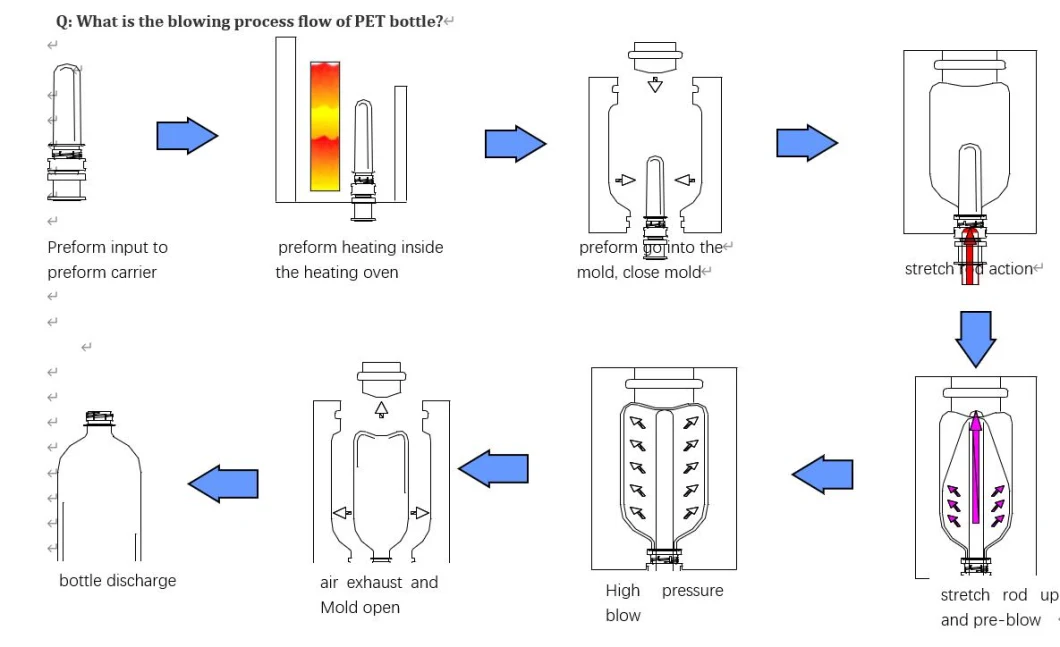

PET bottle blowing process flow chart

We have a professtional after-sale service team, before machine arrive, we will give consulting service about the machine place, eletricity, and water prepare works. after machine arrive in customer factory, we also send engineer for installation, and make training for customer's engineer, customer should take charge of the engineer travel cost, board and lodging and labor cost.

Training: customers can send technician to vfine factory for 7-10 days training by buyers own charge

Delivery time: 90 days after confirmation of bottle designed and receipt of the down payment

Packing: Included the packing cost..

Guarantee: We promise that our goods are all new and not used. They're made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract. The machine is guaranteed in 12months from the date of commissioning signed or 13months from bill of loading with the normal operation conditions and seller shall be in charge of installation of machine.

Installation: Vfine would send engineer to Any installation outside of China, but buyer shall pay traveling expenses, including but not limited to, air ticket fees, 3 star-level boarding lodging fees, and all expenses for seller engineers' trips, also buyer should be apply the visa for seller's engineers. Buyer need also pay the salary for engineer.

After sales

After checking, within the quality guarantee time, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

After quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems.

Zhongshan Vfine machinery co ltd

Zhongshan Chumful Machinery Co Ltd

website: vfine88.en.made-in-china.com