VFINE - Fully Automatic Pet Bottle Container Tank Blow Blowing Molding Making Moulding Manufacturing Machine Machinery

The technologies are applied to the manufacturing process, some of which contribute to the high efficiency of Fully Automatic Pet Bottle Container Tank Blow Blowing Molding Making Moulding Manufacturing Machine Machinery Blower Molder System Equipment Manufacturer HDPE manufacturing and others ensure the stable and durable performance of the product.At present, the product is widely used in the field(s) of Blow Molding Machine with its multi-functional characteristics.

Zhongshan Vfine Machinery Co., Ltd keeping up with market development trends, advancing with the times, through professional industry analysis and precise market positioning, relying on strong production strength and strong technical force, Fully Automatic Pet Bottle Container Tank Blow Blowing Molding Making Moulding Manufacturing Machine Machinery Blower Molder System Equipment Manufacturer HDPE have been manufactured. Innovation ability is the key to the core competitiveness of products. Zhongshan Vfine Machinery Co., Ltd will always stick to the business principle of 'quality first, customers foremost' and strive towards building an even more competitive and capable company aiming for an even better future.

| Automation | Automatic | Computerized | Computerized |

| Certification | CE, ISO9001:2008 | Product | Moulding Machine |

| Transport Package | Wooden Package | Specification | 4500*2000*2500(LWH) mm |

| Trademark | VFINE | Origin | China Guangzhou |

| HS Code | 8477109000 | Production Capacity | 100set/Year |

| Package size per unit product | 400.00cm * 200.00cm * 250.00cm | Gross weight per unit product | 5000.000kg |

Product Description

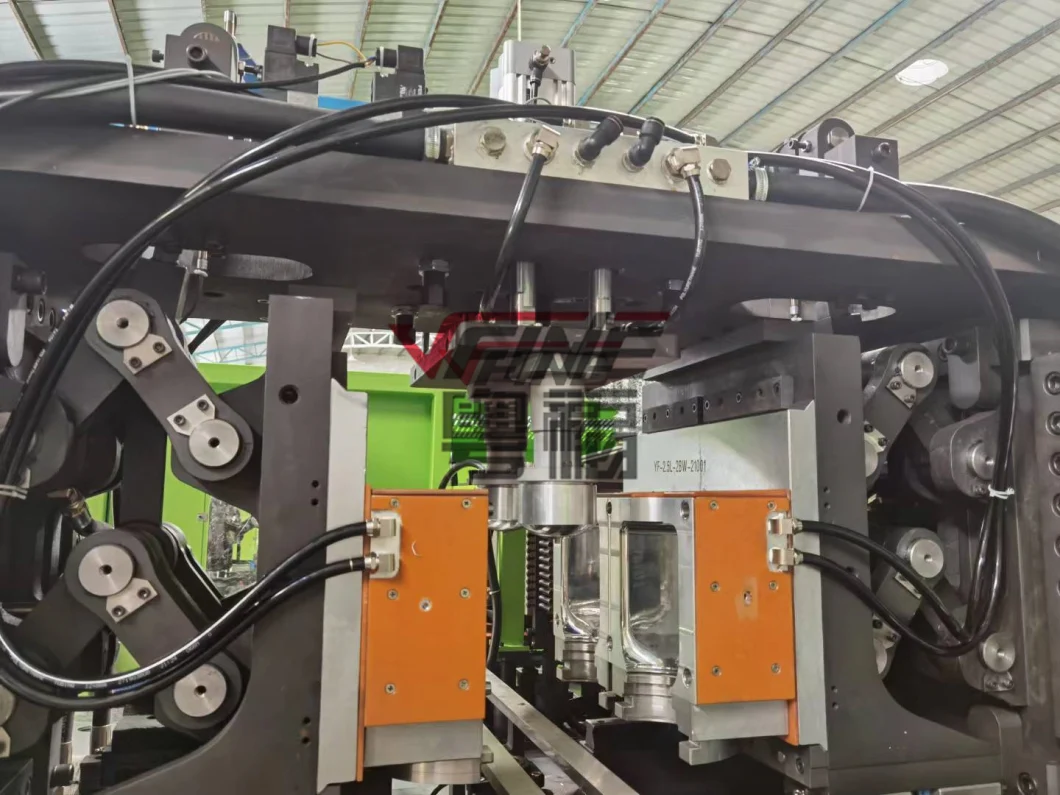

(1)Vfine blowing machine YF-2BLE

3-cavity, linear stretch blowing molding machine

Output: 1300-1500bph

Max. Volume: 6L

(2)application scope

Suitable for producing PET water bottle, carbonate bottle, middle temperature filling bottle etc.

(3)advantage of full electrical Vfine blowing machine

Linear structure, modular design, easy maintenance;

Full servo system

Easy change mould

Save energy

The machine includes auto-lubricating system; ensure the machine running stable and efficiency.

Safety

(4) Vfine blowing machine YF-2BLE specifications

| MODEL | YF-2BLE |

| Max Bottle Volumn | 6L |

| Cavity number | 2 |

| output | 1000-1500BPH |

| Machine size | 4500*2000*2500mm |

| Machine weight | 6500kg |

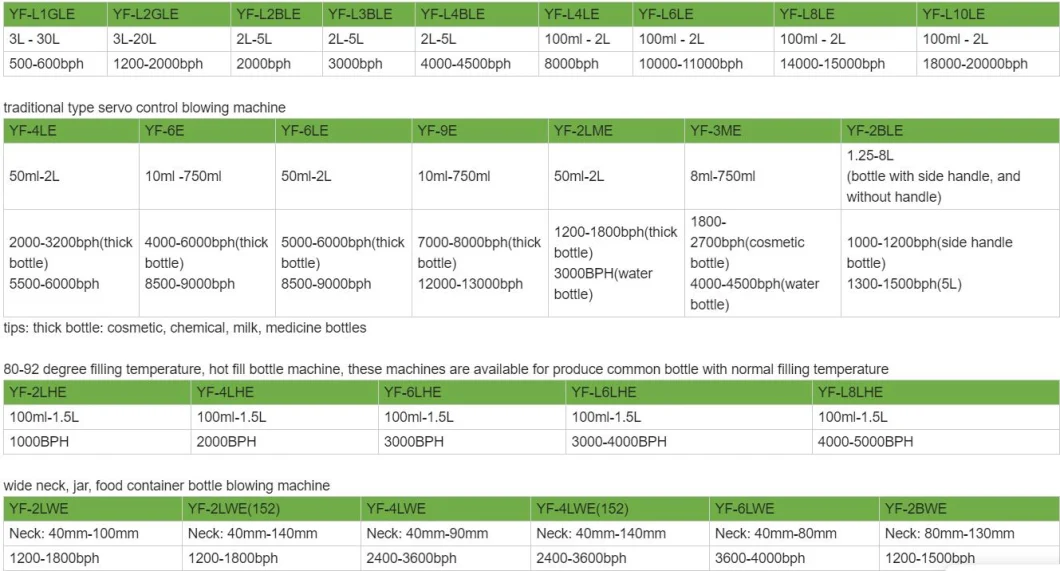

VFINE MACHINERY PRODUCT LIST SHORT VIEW

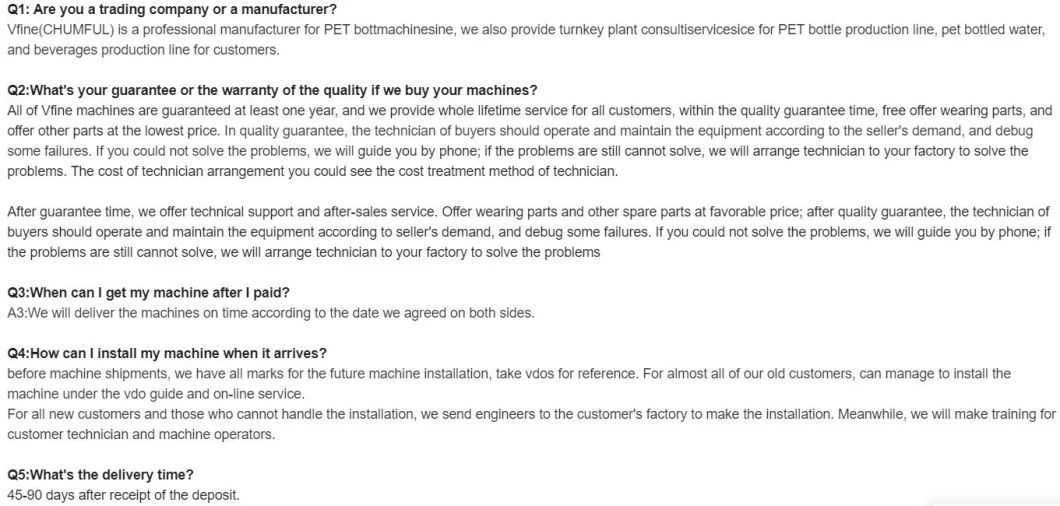

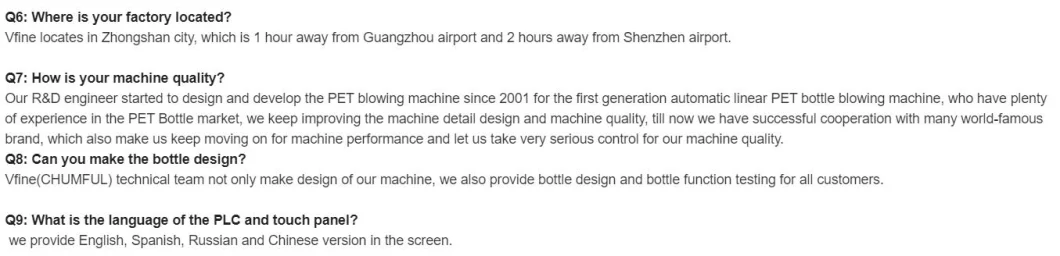

We have a professtional after-sale service team, before machine arrive, we will give consulting service about the machine place, eletricity, and water prepare works. after machine arrive in customer factory, we also send engineer for installation, and make training for customer's engineer, customer should take charge of the engineer travel cost, board and lodging and labor cost.

Not only blow machine, we also provide turnkey project service of pet bottle design, PET bottling equipment line, PET bottle filling, and packing.

zhongshan vfine machinery co ltd

zhongshan Chumful machinery co ltd