VFINE - Fully Automatic Auto Pet Preform Jar Stretch Bottle Candy Food Container Transparent Clear Blow Blowing Molding

After the Fully Automatic Auto Pet Preform Jar Stretch Bottle Candy Food Container Transparent Clear Blow Blowing Molding Moulding Forming Making Machine Factory Maker was launched, we received good feedback, and our customers believed that this type of product could meet their own needs.In addition,It is designed based on customer’s requirement.

As one of the most popular products, Fully Automatic Auto Pet Preform Jar Stretch Bottle Candy Food Container Transparent Clear Blow Blowing Molding Moulding Forming Making Machine Factory Maker wins increasing popularity. Fully Automatic Auto Pet Preform Jar Stretch Bottle Candy Food Container Transparent Clear Blow Blowing Molding Moulding Forming Making Machine Factory Maker Zhongshan Vfine Machinery Co., Ltd will strive toward excellence by building our working principles of guaranteeing quality for survival and seeking innovation for development, into everything we deliver. We are confident that we will overcome all the difficulties and obstacles to make a success in the end.

| Model NO. | YF-2LW | Making Method of Parison | Stretch Blow |

| Automation | Automatic | Computerized | Computerized |

| Certification | CE, ISO9001:2008 | After-sales Service | Life Time Service |

| Transport Package | Wooden Package | Specification | 2.9*2*2m(L*w*h) |

| Trademark | VFINE | Origin | China Guangzhou |

| HS Code | 8477109000 | Production Capacity | 100set/Year |

| Package size per unit product | 300.00cm * 200.00cm * 250.00cm | Gross weight per unit product | 5000.000kg |

Product Description

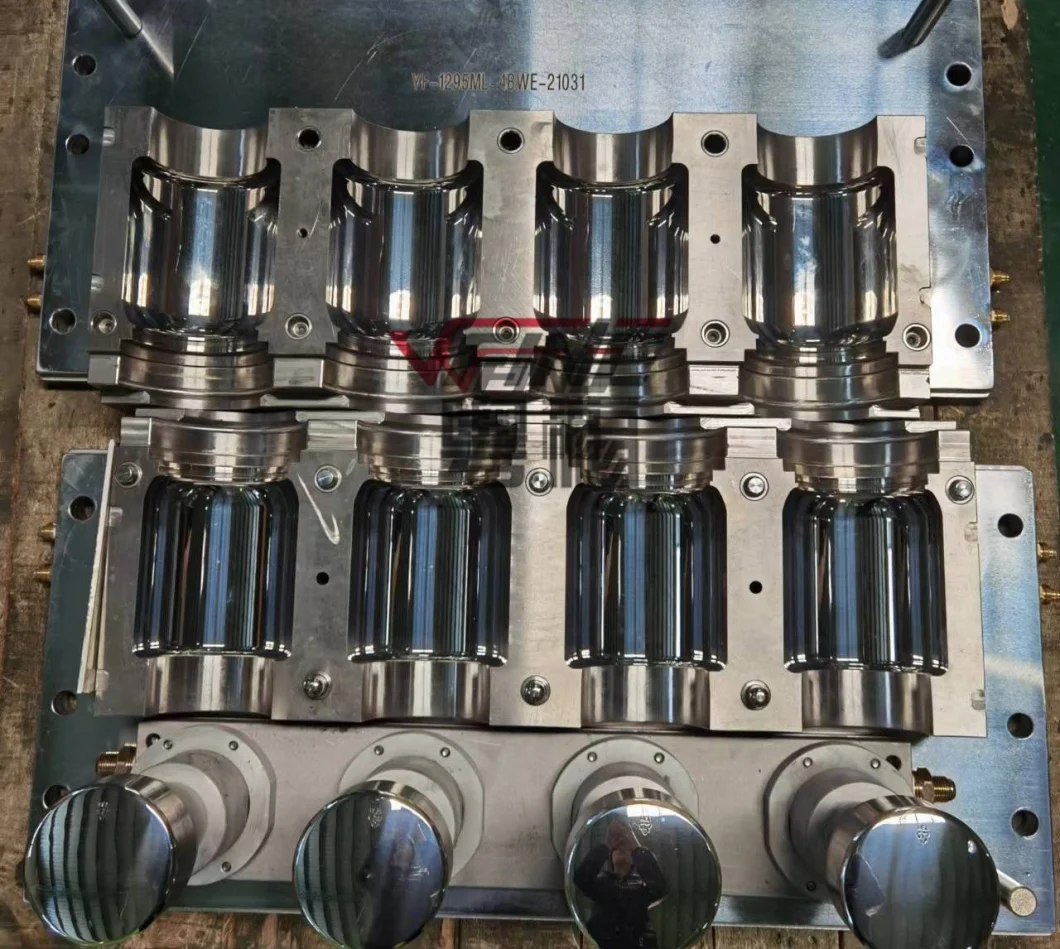

Vfine Jar Series Blowing Machine YF-2LWE

2-cavity, linear stretch blowing molding machine

Output: 1600-2500bph

Max. Volume: 2L

Max bottle neck size: 100mm

Application scope

Advantage of Vfine Cosmetics/Medicine Series Blowing Machine

Linear structure, modular design, easy maintenance;

Servo motor clamping unit, the machine is accurate and very quite

static elimination device

Easy change mould

Safety

PET Vfine Cosmetics/Medicine Series Blowing Machine YF-2LWE specifications

| Model | YF-2LWE |

| Max bottle volumn | 2000ml |

| Number of cavity | 2 |

| ouput | 1600-2000BPH |

| Machine size | 2900*2150*2500mm |

| Machine weight | 3000kg |

We have a professtional after-sale service team, before machine arrive, we will give consulting service about the machine place, eletricity, and water prepare works. after machine arrive in customer factory, we also send engineer for installation, and make training for customer's engineer, customer should take charge of the engineer travel cost, board and lodging and labor cost.

Not only blow machine, we also provide turnkey project service of bottle design, bottling equipment line, bottle filling, and packing.

A: yes, the machine is available for 3L-10L water bottle, edible oil bottle, etc

Q11: is the blowing machine full electrical

A: the machine is control by full servo for all units, no need prepare low pressure air for the blowing machine

Q12: is the blowing machine available for different bottle mold

A: yes, the machine is designed with very easy bottle mold change unit, only need 30minutes to change a mold