VFINE - Pure Minural Water Liquid Bottle Rotary Capsule Bottling Automatic Filling Filler Packing Machine Equipment Pric

At our company, super critical technologies are used to manufacture and test the product.In the application field(s) of Filling Machine,Pure Minural Water Liquid Bottle Rotary Capsule Bottling Automatic Filling Filler Packing Machine Equipment Price Manufactures China functions perfectly and has brought expected benefits to customers.

The core competitiveness of a company is its capabilities in research and development.Zhongshan Vfine Machinery Co., Ltd, as a technology-driven enterprise, has been striving forward to enhance our R&D capabilities and successfully developed Pure Minural Water Liquid Bottle Rotary Capsule Bottling Automatic Filling Filler Packing Machine Equipment Price Manufactures China. Designed by professional designers, Pure Minural Water Liquid Bottle Rotary Capsule Bottling Automatic Filling Filler Packing Machine Equipment Price Manufactures China is attractive in its appearance. Zhongshan Vfine Machinery Co., Ltd have long desired to become one of the most influential enterprises in the industry. At present, we are busy improving our capabilities in product manufacturing, and gathering talents especially technical talents to develop our own core technologies.

| Model NO. | filler 24-24-8 | Automatic Grade | Fully Automatic |

| Material Type | Liquid | Filling Valve Head | Multi-Head |

| Feed Cylinder Structure | Multi-Room Feeding | Dosing Device | Capacity Cup |

| Filling Principle | Back Pressure | Packaging Container Lifting Structure | Chute Pneumatic Combination Lifting |

| Structure | Rotary | Packaging | Bottle |

| Packaging Material | Plastic | Transport Package | Wooden Package |

| Origin | China | Production Capacity | 100set/Year |

| Package size per unit product | 300.00cm * 230.00cm * 230.00cm | Gross weight per unit product | 3000.000kg |

Product Description

3 in 1 bottle pure / minural water filling machine

Working process

The bottle enters into the rinsing part of three-in-one machine through air conveyor. The gripper installed on the rotary disk catches bottle and turns it over 180 degrees and makes the bottleneck face ground. In the special rinsing area, the nozzle on the gripper sprays water to rinse bottle inwall. After rinsing and draining, the bottle turns over 180 degrees along the guide rail and make the bottleneck faces sky. Then rinsed bottle is transferred to the filling part through poking bottle starwheel. The bottle that enters into the filler is hold by neck holding plate. The filling valve acted by the cam can realize up and down. It adopts pressure filling way. The filling valve opens and begins filling when it moves down and touches the bottleneck, the filling valve move up and leave the bottleneck when it finishes filling, the full bottle is transferred to the capping part through hold neck transition poking wheel.

The stop screwing knife holds the bottleneck, keeps bottle upright not rotating. The screw capping head keeps in revolution and autorotation. It can finish a whole capping course including catching, pressing, screwing, discharging through the action of the cam. The full bottle is transferred to bottle outlet conveyor to the next process through starwheel. The whole machine is enclosed with windows, the height of enclosed window is higher than the peak of the 3 in 1 machine, in the bottom of the enclosed window has return air outlet.

Features of equipment

1) The machine has compact structure, perfect control system, convenient operation and high degree of automation.

2) Parts in contact with materials are made of high quality stainless steel, corrosion resistant, easy to clean.

3) High precision, high speed quantitative filling valve, accurate liquid level without liquid loss, to ensure excellent filling quality.

4) The capping head adopts constant torque device, which ensures the capping quality and will not damage the cap.

5) Adopt efficient cover management system, perfect cover feeding and protection device.

6) With a perfect cleaning management system to ensure the quality of washing before filling.

7) Changing bottle shape, only need to replace the star wheel, bottle feed screw and arc plate can be realized, simple and convenient operation.

8) Equipped with perfect overload protection device, can effectively protect the safety of the machine and the operator.

9) The machine adopts frequency conversion speed regulating motor, which can easily adjust the production capacity.

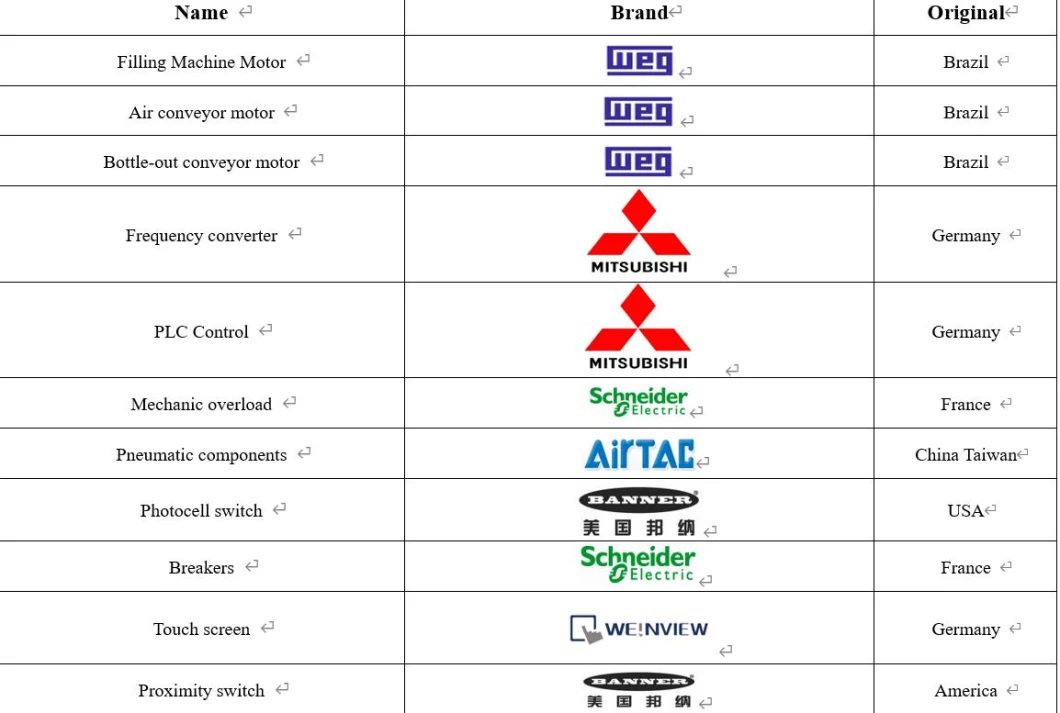

10) The main electrical components, frequency converters, photoelectric switches, proximity switches, electronic valves and other imported components are used to ensure the excellent performance of the machine.

11) The control system has the functions of automatic water level control, missing cap detection alarm, automatic stop alarm and shift output count.

12) All components of air path system are imported products.

Main technical parameters

Number of work stations: washing 24, filling 24, capping 8

Production capacity: 14000 bottles/hour (500ml/ bottle)

Use bottle type: φ 50- φ 115mm H=150-320mm

Air source pressure: 0.7mpa

Air consumption: 1.0m3 /min Bottle water pressure: 0.2-0.25mpa

Bottle water consumption: 0.8-1.0t/hour Main motor power: 3KW

Dimensions: 2880×2180×2450 MM

Machine weight: 7500kg

MAIN SPARE PART LIST

We have a professional after-sale service team, before the machine arrive, we will give consulting service about the machine's place, electricity, and water preparation works. after the machine arrives in the customer's factory, we also send the engineer for installation and make training for the customer's engineer, customer should take charge of the engineer's travel cost, board and lodging , and labor cost.

Zhongshan chumful machinery co ltd is the one branch of Zhongshan Vfine machinery co ltd, which is a professional manufacturer of PET bottle blowing machines, that integrates the R&D, production, and sales. Since the development and design of the first generation linear automatic stretch blow molding machine, Vfine's technical team has focused in the PET market for 20 years. We've successfully supplied machines to many world-famous brands. Not only the bottle blowing machine,Vfine(CHUMFUL) also provide the turnkey plant service for all customers, we can offer from A to Z solution for all kind of PET bottle production, PET bottle water, and pet bottle beverage.

![Pure Minural Water Liquid Bottle Rotary Capsule Bottling Automatic Filling Filler Packing Machine Equipment Price Manufactures China]()

![Pure Minural Water Liquid Bottle Rotary Capsule Bottling Automatic Filling Filler Packing Machine Equipment Price Manufactures China]()

![Pure Minural Water Liquid Bottle Rotary Capsule Bottling Automatic Filling Filler Packing Machine Equipment Price Manufactures China]()

Vfine sales consultant

1. We can provide comprehensive and professional Suggestions on equipment selection.

2. Energy consumption calculation and investment income analysis can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product optimization Suggestions.

4. The stretch plastic bottle blow molding machine has remote maintenance function

Advantages of Vfine tech teams

1. Many sets of customized machines in the market enable us to have rich experience across multiple industries.

2. Customize equipment models according to customer product characteristics.

3. Project responsibility system, closed-loop team cooperation between the design team and the process team, adjustment of the team, and joint creation of equipment that users are satisfied with.

4. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry.

5. Undertake a number of large projects, and has a group of senior technical personnel composed of the construction team, can build cable bridge, installation of a complete set of equipment.

Advantages of Vfine Machinery after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment.

5. Free training for customer technician while making installation

6. Special processing equipment to produce after-sales accessories to ensure rapid response to user needs.

Q1: Are you a trading company or a manufacturer?

Vfine(CHUMFUL) is a professional manufacturer for PET bottmachinesine, we also provide turnkey plant consultiservicesice for PET bottle production line, pet bottled water, and beverages production line for customers.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

All of Vfine machines are guaranteed at least one year, and we provide whole lifetime service for all customers, within the quality guarantee time, free offer wearing parts, and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to the seller's demand, and debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still cannot solve, we will arrange technician to your factory to solve the problems. The cost of technician arrangement you could see the cost treatment method of technician.

After guarantee time, we offer technical support and after-sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, and debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still cannot solve, we will arrange technician to your factory to solve the problems

Q3:When can I get my machine after I paid?

A3:We will deliver the machines on time according to the date we agreed on both sides.

Q4:How can I install my machine when it arrives?

before machine shipments, we have all marks for the future machine installation, take vdos for reference. For almost all of our old customers, can manage to install the machine under the vdo guide and on-line service.

For all new customers and those who cannot handle the installation, we send engineers to the customer's factory to make the installation. Meanwhile, we will make training for customer technician and machine operators.

Q5:What's the delivery time?

45-90 days after receipt of the deposit.

Q6: Where is your factory located?

Vfine locates in Zhongshan city, which is 1 hour away from Guangzhou airport and 2 hours away from Shenzhen airport.

Q7: Can you make the bottle design?

Vfine(CHUMFUL) technical team not only make design of our machine, we also provide bottle design and bottle function testing for all customers.

Q12: Do you provide customized service

Yes, VFINE(chumful) technical team gets plenty of experience in the pet BOTTLE market, we have lots of customized designs according to customer requirements, the special bottleneck, the special label, and the special bottle shape, and the bottle function.

Warmly welcome you to visit my factory, please don't hesitate to contact us if you have any questions.

Any futher information needed, please dont hestage to contact me

Vincent Wen