About VFINE

In 2010, we develop the first servo machine for PET, which is 1500BPH per cavity. In 2013, we develop the high-speed servo machine, which is 1800bph per cavity. In 2016, we establish Chumful machinery, which handles all the export issues for our oversea customers. In 2019, our high-speed servo machine is 2000-2200bph per cavity for the normal water bottle. Nowadays, we still keep developing our product and keep leading the development of the bottle production industry We've successfully supplied machines to many world-famous brands, such as Yily, Mengniu, Liby, Cestbon, Blue moon, and water Waston. ![Best Quality water bottle making machine manufacturers & supplier - vfine Factory 1]()

Our machines have been offered to worldwide, such as USA, Canada, Spain, Turkey, Singapore, Malaysia, Russia, Ethiopia, Japan, Columbia, and some other 50 countries. We not only supply the bottle blowing machine, but also provide the turnkey plant service for all customers, we are a one-step solution supplier for PET, PP, and HDPE bottle production can offer from A to Z solutions for all kinds of plastic bottle production, water bottling, and beverage line. Product Introduction

![Best Quality water bottle making machine manufacturers & supplier - vfine Factory 3]()

The L series machine is full servo control and smart PET bottle making machine, it is avaiable for bottle from 50ml to 2L for water, milk, juice, ice tea, carbonate, medicine, shampoo containers. with single channel preform infeeding, and protect from preform get blocked, the production capacity of the equipment is not less than 2000 bottles/hour/per cavity; the equipment combines the advantages of the rotary machine and the linear machine, with a high energy utilization rate and simple and convenient operation

01

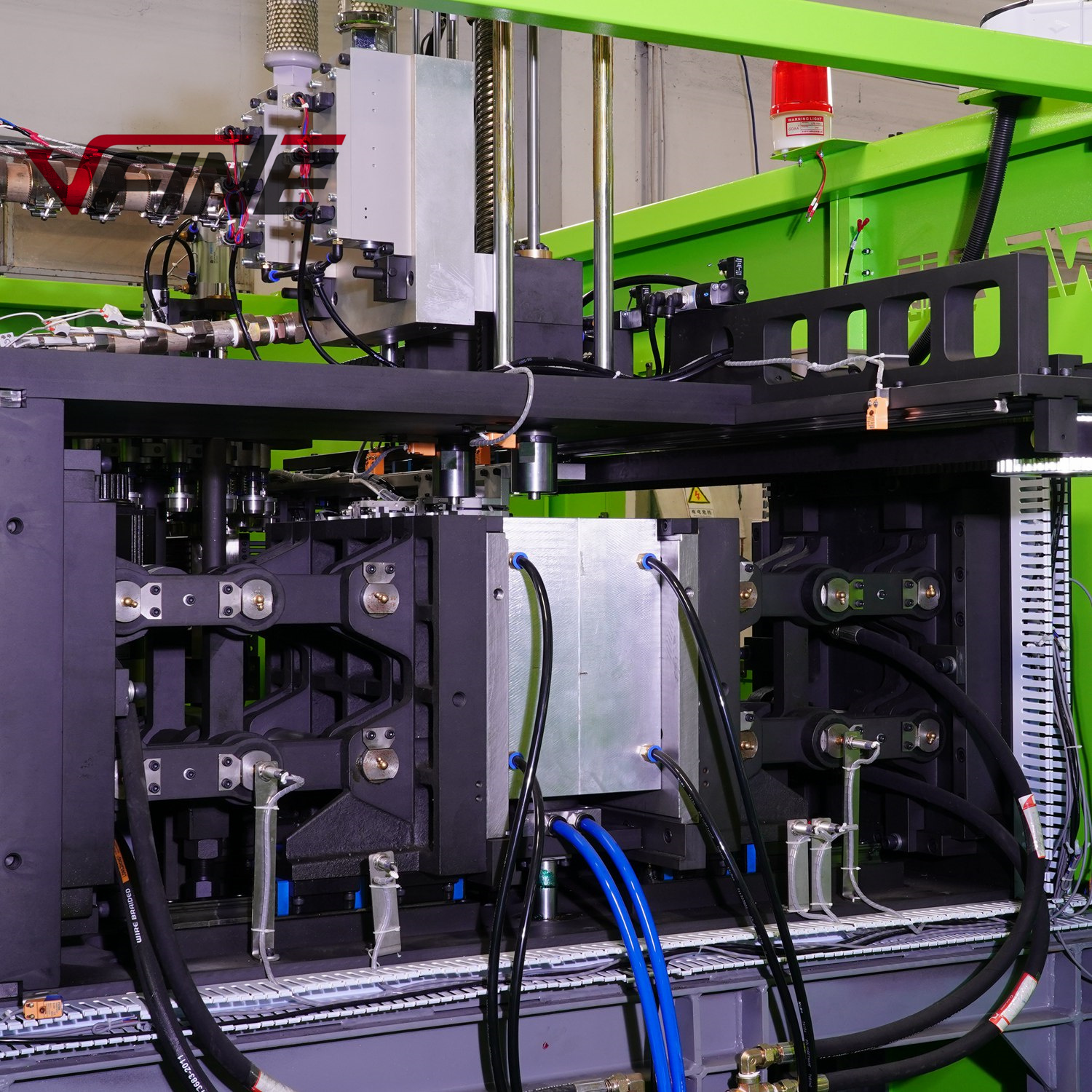

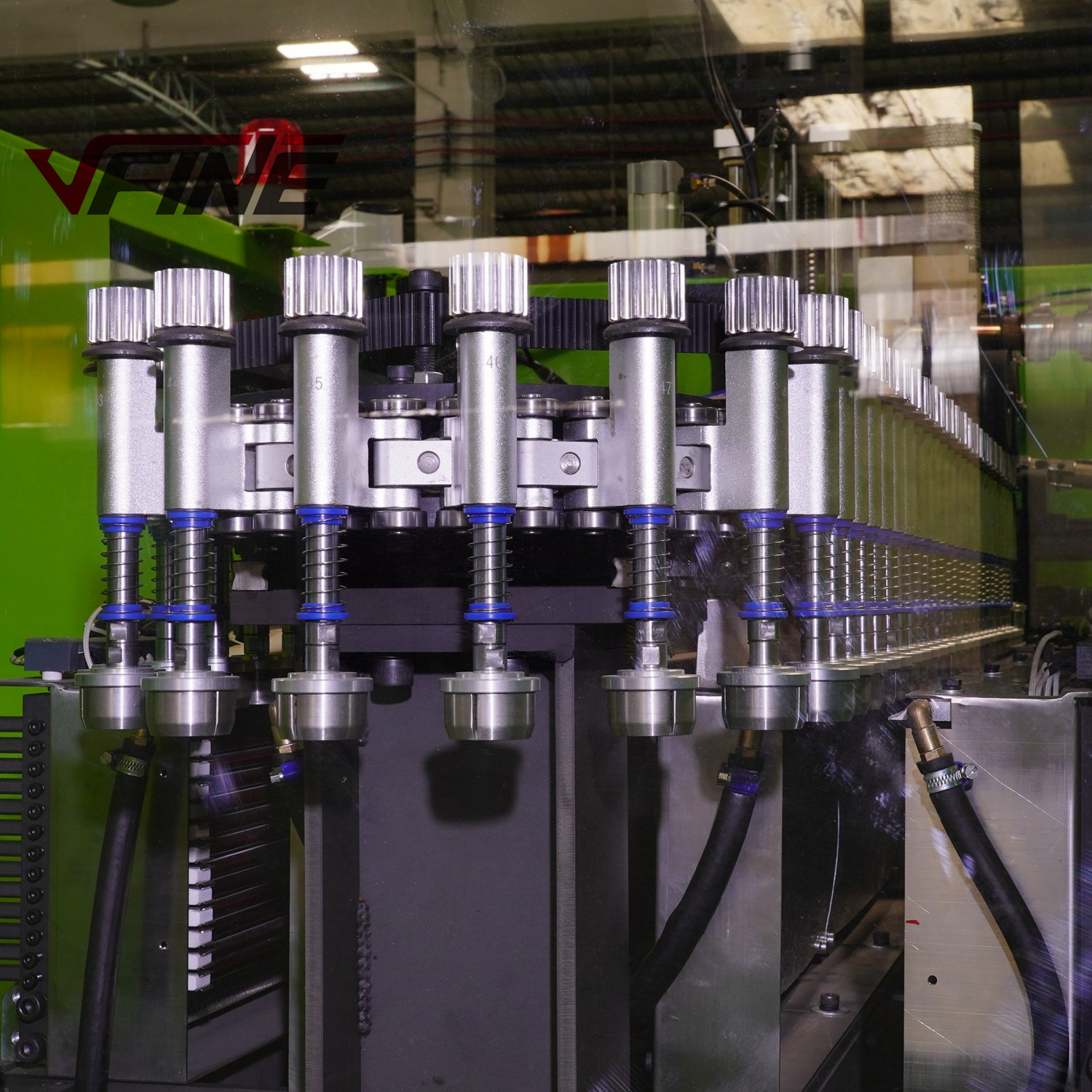

clamping unit

The whole machine clamping plates are with anneal treatment, and are processed by CNC at one time, so they are quite strong and accurate. The high pressure air compensation device ensure high quality bottle with nice parting shape

02

compact design

The machine infeeding are inside the machine, which save the space occupation. There is no loading jam on the infeeding unit.

03

high and balance heating

The heating unit is with frequency conversion, and controlled by very powerful heating controller, which can ensure the machine heating output in the constant range

Product specifications

| items | High speed 4 cavity bottle blow molding machine |

| machine model | YF-L4LE |

| machine production capacity | 8000BPH |

| cavity number | 4 |

| bottle capacity | 50ml to 2L |

| actual running power | 15-20KW/H |

| machine weight | 6000kg |

| machine size | 420*190*250cm |

Company Advantages

Lifetime free service for the machine.

Quick response all day long.

We can provide comprehensive and professional Suggestions on equipment selection.

Frequently Asked Questions about water bottle manufacturing machine

Q:Can you make the bottle design?

A:Vfine(CHUMFUL) technical team not only make design of our machine, we also provide bottle design and bottle function testing for all customers.

Q:Are you a trading company or a manufacturer?

A:Vfine(CHUMFUL) is a professional manufacturer for PET bottmachinesine, we also provide turnkey plant consultiservicesice for PET bottle production line, pet bottled water, and beverages production line for customers.

Q:What is the language of the PLC and touch panel?

A:we provide English, Spanish, Russian and Chinese version in the screen.

Q:Where is your factory located?

A:Vfine locates in Zhongshan city, which is 1 hour away from Guangzhou airport and 2 hours away from Shenzhen airport.

Q:How can I install my machine when it arrives?

A:before machine shipments, we have all marks for the future machine installation, take vdos for reference. For almost all of our old customers, can manage to install the machine under the vdo guide and on-line service.

For all new customers and those who cannot handle the installation, we send engineers to the customer's factory to make the installation. Meanwhile, we will make training for customer technician and machine operators.