VFINE bottle blowing machine meets the CE,ISO standard. It is suitable for blowing plastic containers and bottles of any shape with pet, PP as raw materials. It is widely used in blowing carbonated beverage bottles, mineral water bottles, milk bottles, oil bottles, oil bottles, cosmetic bottles, pesticide bottles, medical bottles.

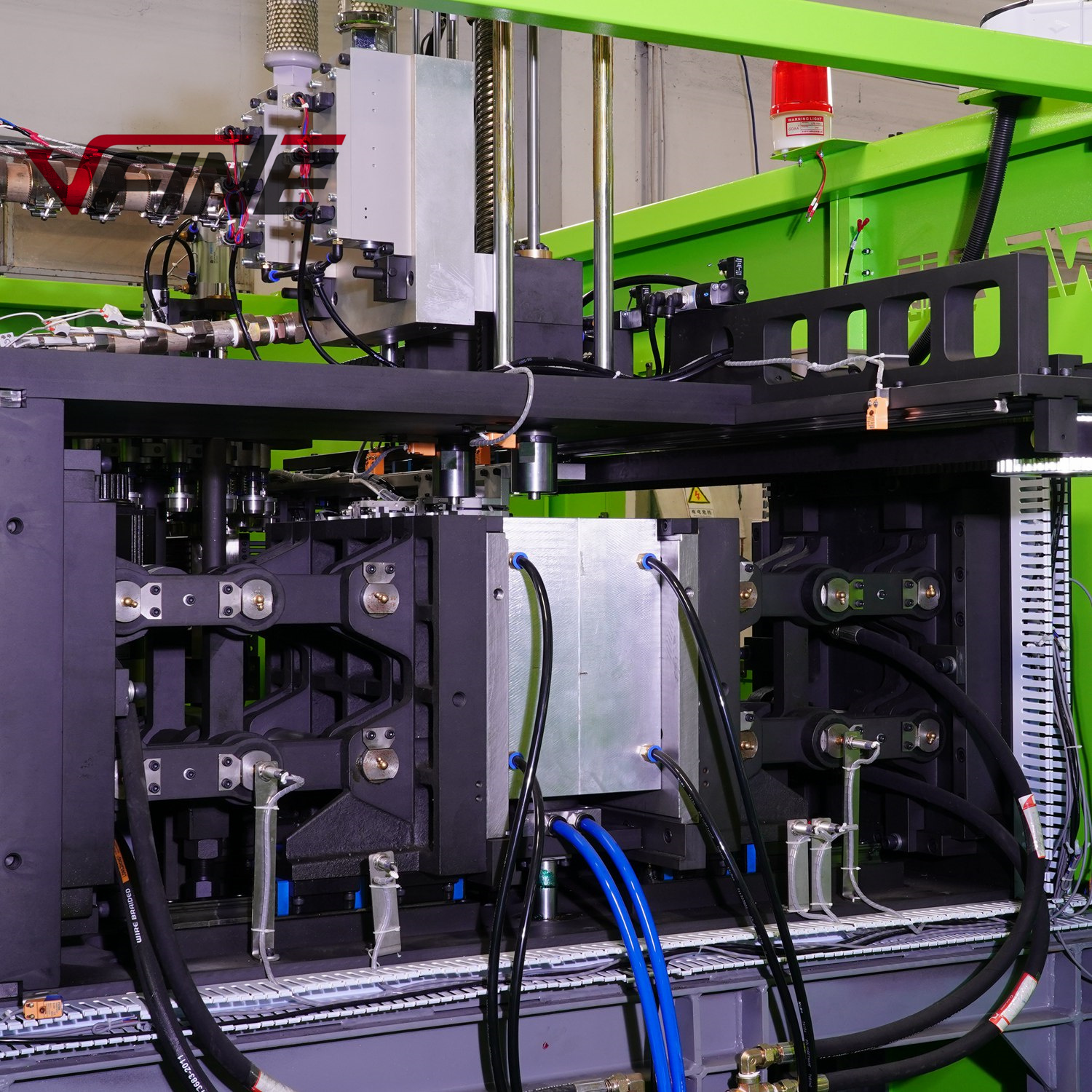

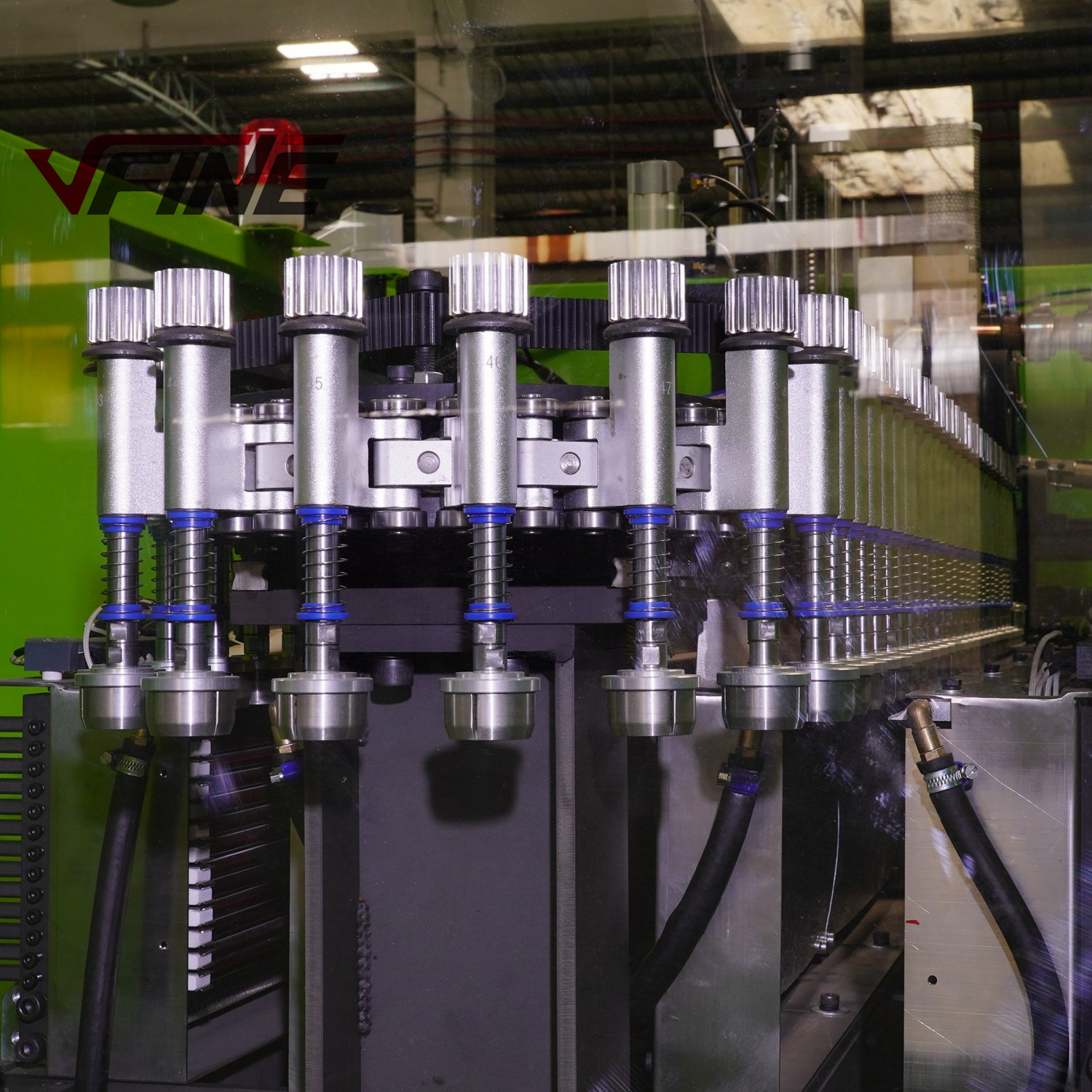

oil bottle 4cavity blowing machine

Product Introduction

The L series machine is full servo control and smart PET bottle making machine, it is avaiable for bottle from 50ml to 2L for water, milk, juice, ice tea, carbonate, medicine, shampoo containers. with single channel preform infeeding, and protect from preform get blocked, the production capacity of the equipment is not less than 2000 bottles/hour/per cavity; the equipment combines the advantages of the rotary machine and the linear machine, with a high energy utilization rate and simple and convenient operation.

Product Advantages

Product specifications

| items | High speed 4 cavity bottle blow molding machine |

| machine model | YF-L4LE |

| machine production capacity | 8000BPH |

| cavity number | 4 |

| bottle capacity | 50ml to 2L |

| actual running power | 15-20KW/H |

| machine weight | 6000kg |

| machine size | 420*190*250cm |

About VFINE

In 2010, we develop the first servo machine for PET, which is 1500BPH per cavity. In 2013, we develop the high-speed servo machine, which is 1800bph per cavity. In 2016, we establish Chumful machinery, which handles all the export issues for our oversea customers. In 2019, our high-speed servo machine is 2000-2200bph per cavity for the normal water bottle. Nowadays, we still keep developing our product and keep leading the development of the bottle production industry We've successfully supplied machines to many world-famous brands, such as Yily, Mengniu, Liby, Cestbon, Blue moon, and water Waston.

Our machines have been offered to worldwide, such as USA, Canada, Spain, Turkey, Singapore, Malaysia, Russia, Ethiopia, Japan, Columbia, and some other 50 countries. We not only supply the bottle blowing machine, but also provide the turnkey plant service for all customers, we are a one-step solution supplier for PET, PP, and HDPE bottle production can offer from A to Z solutions for all kinds of plastic bottle production, water bottling, and beverage line.

|

|

Company Advantages

VFINE wil send the experienced technician to guide the installation and trail production.

Training

VFINE will supply technical training to the customers. The training includes: equipment structure and maintenance, control and operationAfter training, the technicians ofthe buyer willgrasp relevant operation and maintenance skils, and could adjust the technologies more skiledand can deal with all kinds of malfunction in time.

After-sales service

1) After qualified of the equipment, we will supply one-year guarantee, control system one-year guarantee.

2) lf the technicians ofthe buyer couldn't solve the problems themselves, the after-sales department wilsupply long distance guide service

3) If relevant measurements couldn't solve the problems, the seller wil send the technicians to the buyer factory, clear the fault or relevanttechnical problems on site, the charges will reference to the installation and debugging charges.

Frequently Asked Questions about water bottle manufacturing machine