6 Cavity Fully Automatic Pet Bottle Stretch Blow Molding Machine - High Speed & Quality

Product features

Our 6 Cavity Fully Automatic Pet Bottle Stretch Blow Molding Machine offers high-speed production and superior quality, making it an ideal choice for plastic bottle making machine price suppliers. With a focus on core attributes like efficiency and precision, this machine can cater to various production needs with ease. Its value attributes include energy-saving features and safety mechanisms, ensuring a reliable and efficient production process for clients.

Company profile

Our company is a leading manufacturer of high-speed and high-quality pet bottle stretch blow molding machines. With our 6 cavity fully automatic system, we offer unparalleled efficiency and precision in bottle production. Our machines are designed to meet the demands of the modern packaging industry, providing reliable performance and consistent results. We are dedicated to delivering innovative solutions that optimize production processes and enhance product quality. Trust in our expertise and commitment to excellence, as we strive to exceed customer expectations and set new standards in the industry.

Enterprise core strength

Our company is a leading manufacturer of high-speed and high-quality fully automatic pet bottle stretch blow molding machines. With a focus on innovation and customer satisfaction, we have developed a 6 cavity machine that offers unparalleled efficiency and precision in producing PET bottles. Our state-of-the-art technology ensures reliable operation and consistent results, making it the ideal choice for businesses looking to streamline their production process. Our commitment to quality and performance sets us apart in the market, making us the preferred partner for businesses seeking top-tier equipment for their packaging needs. Trust us for exceptional performance and reliable service.

Zhongshan Vfine Machinery Co., Ltd keeping up with market development trends, advancing with the times, through professional industry analysis and precise market positioning, relying on strong production strength and strong technical force, Juice Hot Fill 6 Cavity Fully Automatic Pet Bottle Stretch Blow Blowing Molding Making Moulding Machine Manufacturers High Speed have been manufactured. After the Juice Hot Fill 6 Cavity Fully Automatic Pet Bottle Stretch Blow Blowing Molding Making Moulding Machine Manufacturers High Speed was launched, we received good feedback, and our customers believed that this type of product could meet their own needs. Zhongshan Vfine Machinery Co., Ltd have long desired to become one of the most influential enterprises in the industry. At present, we are busy improving our capabilities in product manufacturing, and gathering talents especially technical talents to develop our own core technologies.

| Model NO. | YF-6LHE | Product | Bottle Blowing Machine |

| Raw Material | Pet | Making Method of Parison | Stretch Blow |

| Automation | Automatic | Computerized | Computerized |

| Certification | CE, ISO9001:2008 | Transport Package | Wooden Package |

| Specification | 5*2.2*2.5m(L*W*H) | Trademark | VFINE |

| Origin | China | HS Code | 8477109000 |

| Production Capacity | 100set/Year | Package size per unit product | 550.00cm * 220.00cm * 250.00cm |

| Gross weight per unit product | 6000.000kg |

Product Description

BOTTLE BLOWING machine for hot fill PET bottle

Vfine Full Electrical hot fill Blowing Machine YF-4LHE

4-cavity, linear stretch blowing molding machine

Output: 2000bph

Max. Volume: 1.5L

Application scope

Suitable for PET hot fill juice, ice tea, energy drink bottle, etc

PET Vfine Full Electrical hot fill Blowing Machine YF-4LHE specifications:

| model | YF-4LHE |

| Max bottle volumn | 1500ml |

| Number of cavity | 4 |

| output | 2000BPH |

| Machine size | 4000*2000*2500mm |

| Machine weight | 6500kg |

PS: Specifications are subjected to change without future notice

Zhongshan chumful machinery co ltd is the one branch of Zhongshan Vfine machinery co ltd, which is a professional manufacturer of PET bottle blowing machines, that integrates the R&D, production, and sales. Since the development and design of the first generation linear automatic stretch blow molding machine, Vfine's technical team has focused in the PET market for 20 years. We've successfully supplied machines to many world-famous brands. Not only the bottle blowing machine,Vfine(CHUMFUL) also provide the turnkey plant service for all customers, we can offer from A to Z solution for all kind of PET bottle production, PET bottle water, and pet bottle beverage.

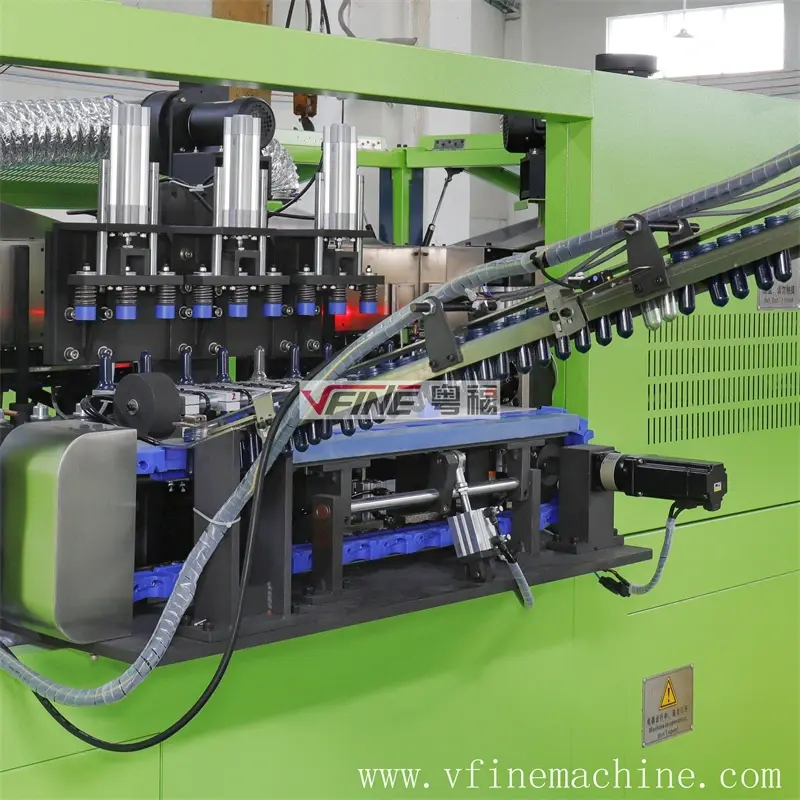

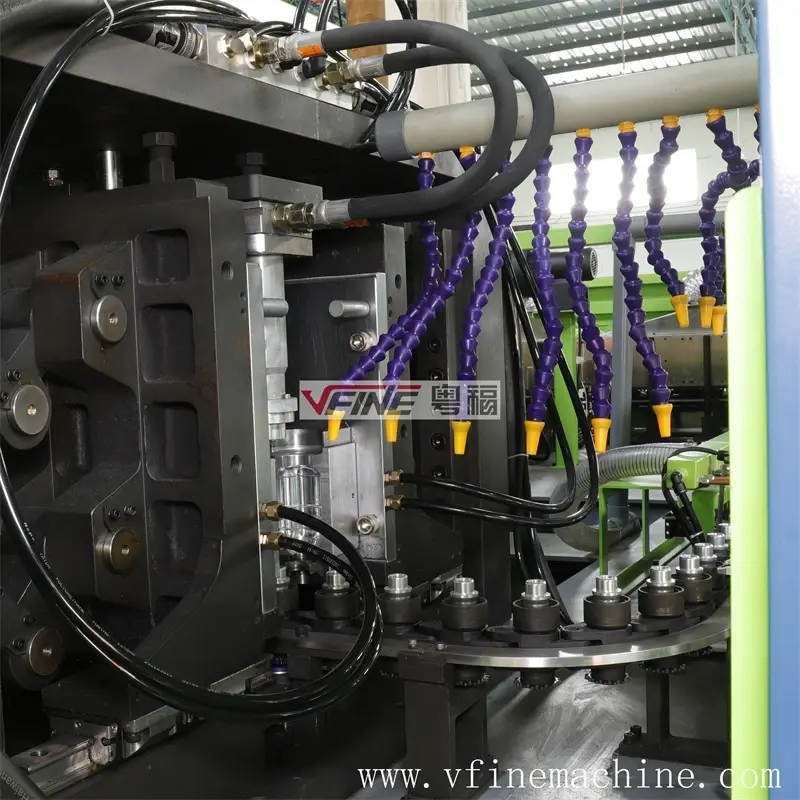

![Juice Hot Fill 6 Cavity Fully Automatic Pet Bottle Stretch Blow Blowing Molding Making Moulding Machine Manufacturers High Speed]()

![Juice Hot Fill 6 Cavity Fully Automatic Pet Bottle Stretch Blow Blowing Molding Making Moulding Machine Manufacturers High Speed]()

![Juice Hot Fill 6 Cavity Fully Automatic Pet Bottle Stretch Blow Blowing Molding Making Moulding Machine Manufacturers High Speed]()

![Juice Hot Fill 6 Cavity Fully Automatic Pet Bottle Stretch Blow Blowing Molding Making Moulding Machine Manufacturers High Speed]()

Advantage of Vfine Full Electrical hot fill Blowing Machine

Linear structure, modular design, easy maintenance;

Full electrical blowing machine, servo motor together with high pressure air compensation device, ensure stable running;

Save energy

The machine includes auto-lubricating system; ensure the machine running stable and efficiency.

Safety

Filling temperature

The filling temperature can be up to 95degree. Use electrical heating controller, very clean, and save energy.

Vfine sales consultant

1. We can provide comprehensive and professional Suggestions on equipment selection.

2. Energy consumption calculation and investment income analysis can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product optimization Suggestions.

4. The stretch plastic bottle blow molding machine has remote maintenance function

Advantages of Vfine tech teams

1. Many customized machines in the market enable us to have rich experience across PET bottling production.

2. Customize equipment models according to customer product characteristics.

3. Project responsibility system, closed-loop team cooperation between the design team and the process team, adjustment of the team, and joint creation of equipment that users are satisfied with.

4. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry.

5. Undertake a number of large projects, and has a group of senior technical personnel composed of the construction team, can build cable bridge, installation of a complete set of equipment.

Advantages of Vfine Machinery after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment.

5. Free training for customer technician while making installation

6. Special processing equipment to produce after-sales accessories to ensure rapid response to user needs.

Shipping Packing

Under normal conditions, the blow molding machine to abroad will be packaged in wooden case. ln addition, we will also pack the machine according to the requirements of specific customers. Subject to the measurement of main blower, we will choose corresponding wooden case, Vfine Machinery is a professional mould machinery company we will try our best to satisfy the kinds of demand of customers.

Q&A

Q: is the blowing machine suitable for CSD, water bottle

A: yes, the machine is available for water bottle, edible oil bottle, csd bottle, medicine bottle, wine bottle, etc

Q: is the blowing machine full electrical

A: the machine is control by full servo for all units, no need prepare low pressure air for the blowing machine

Q: is the blowing machine available for different bottle mold

A: yes, the machine is designed with very easy bottle mold change unit, only need 30minutes to change a mold

ZHONGSHAN VFINE MACHIENRY CO LTD