pet bottle manufacturing machine1

Machine High Light

1. Fully automatic, full-servo, high-speed, high quality bottle blow molding machine,

2. the production capacity is at least 8500bph

3. Smart mold design, can quickly change the mold within 30 minutes.

4. Intelligent design, pull rod equipment, heating parameter setting, blowing parameter and speed setting can all be completed on the operation screen.

5. Durable machine, low energy cost, Low maintenance cost

6. Application scope: PET bottle for water, Juice, soda, Ice tea, CSD, beer, wine, milk, consident, cooking oil, soy sauce, etc.

| Model | YF-6E |

| Max Bottle Volumn | 750ml |

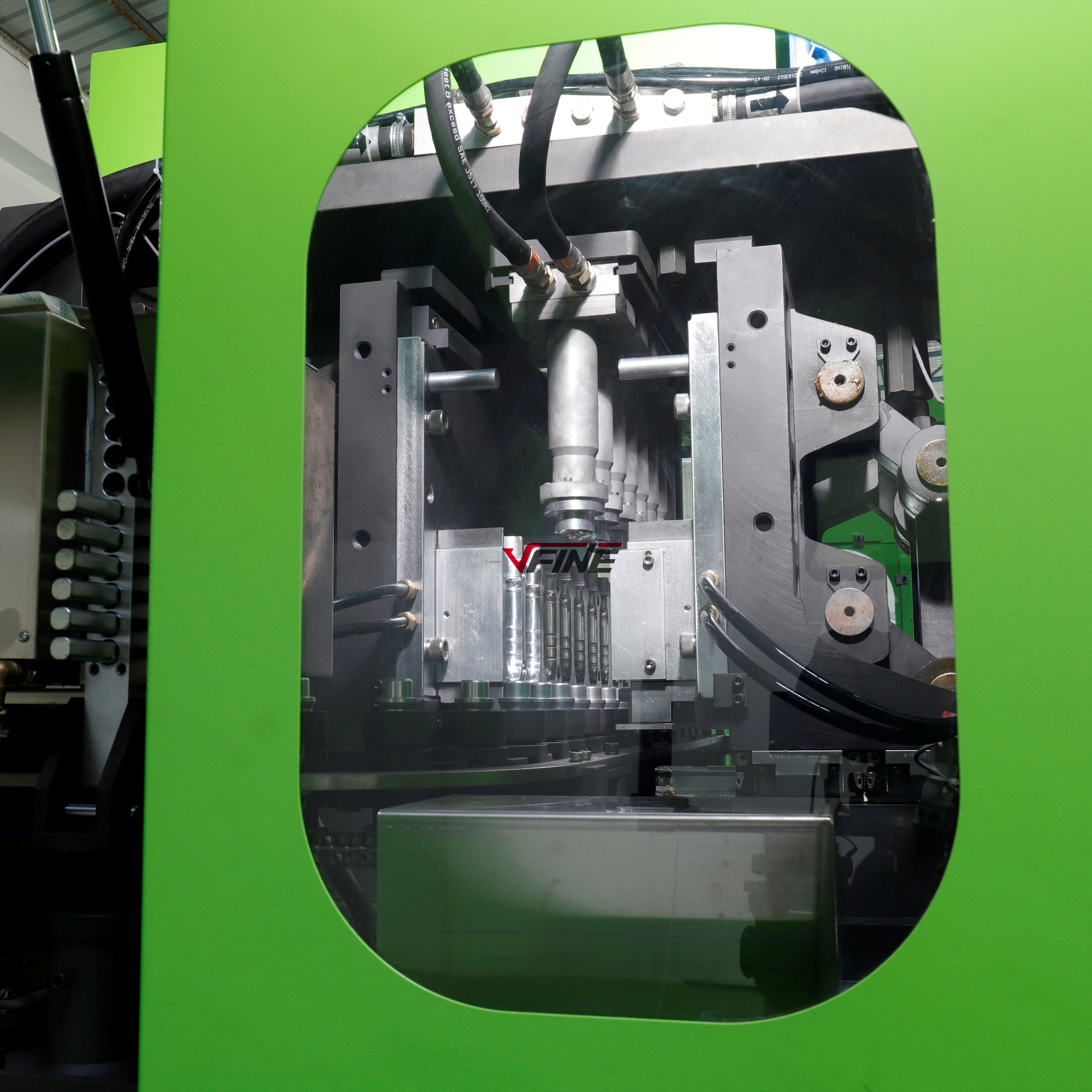

| Cavity Number | 6 |

| Output | 8500-9500BPH |

| Machine Size | 4000*2000*2500mm |

| Machine Weight | 6500kg |

6-cavity, linear stretch blowing molding machine

Output: 8500-9000bph

Max. Volume: 0.75L

(2)APPLICATION

This machine is ideal for start-up and small-scale companies and is reliable, heavy duty, and capable of producing a wide variety of high quality PET bottles for many industries like water, alcohol, juice, liquid detergent, vegetable oil, cosmetics, pharmaceutical and personal care items which are just a few examples.

|

|

|

|

|

|

|

|

Advantages of VFINE Blowing Machine:

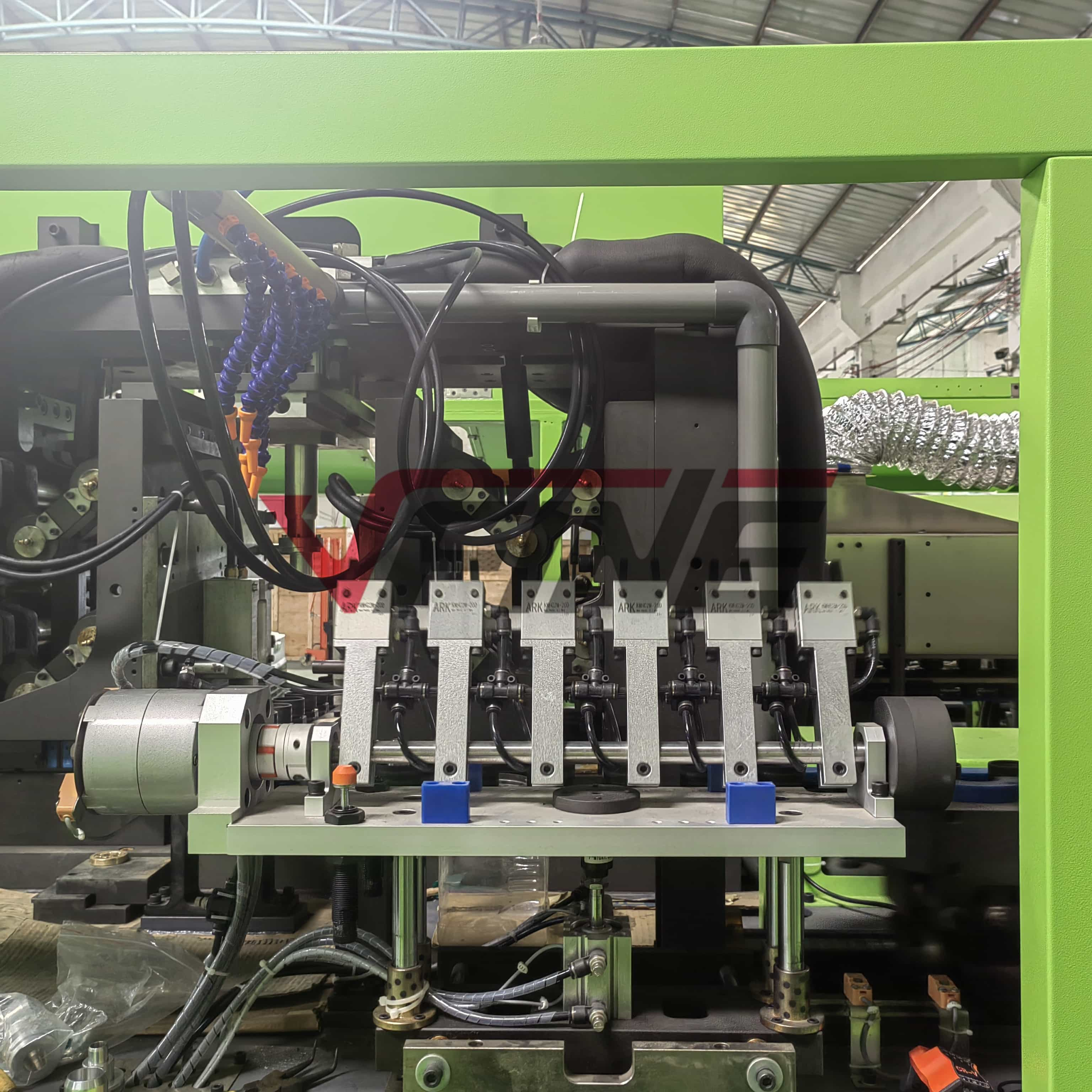

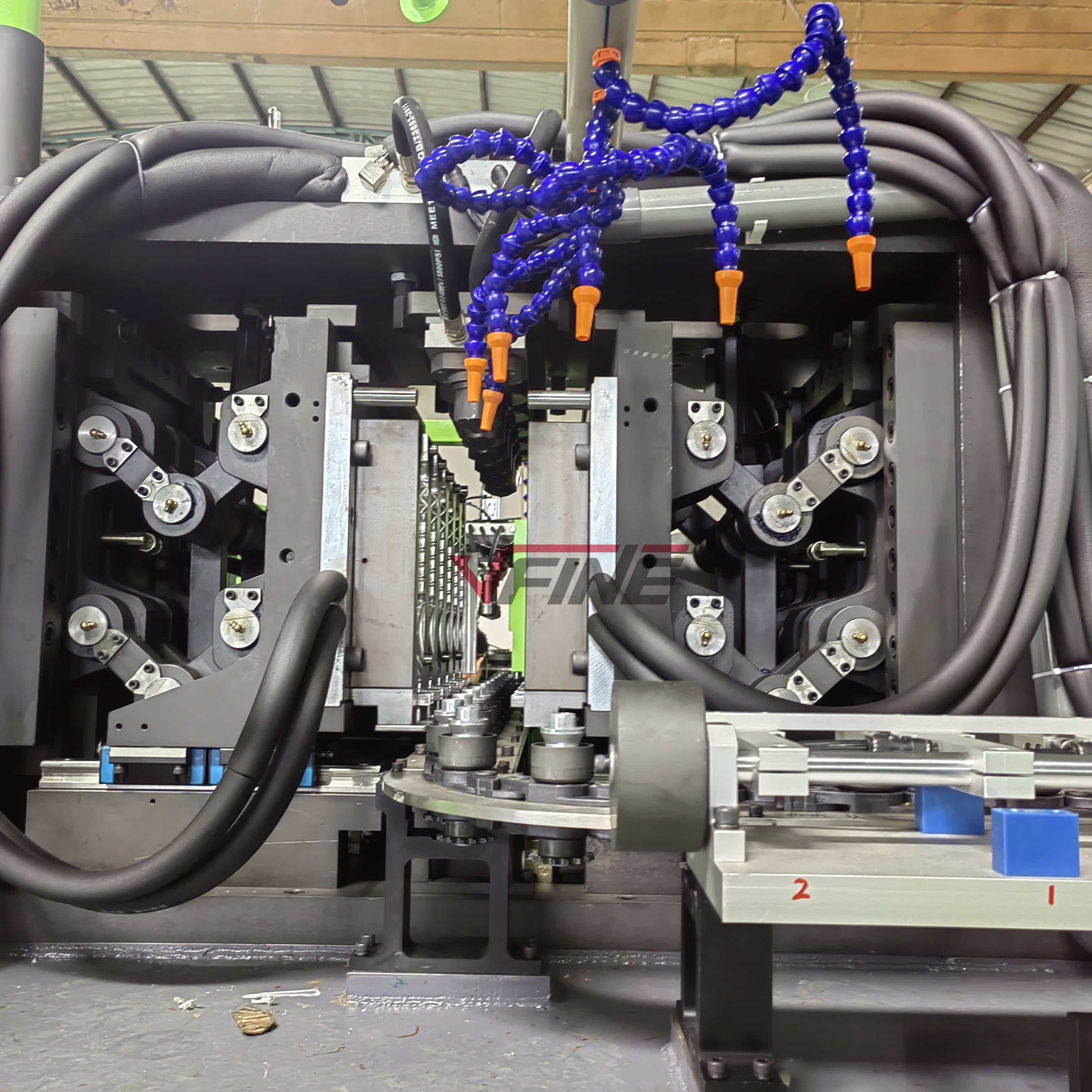

1.Original FESTo air cylinder.

2.Bottles of different sizes can be produced simultaneously to meet your exact requirements.

3.Change over from one size to another can be completed simply and quickly.

4.The tooling costs (molds) are low since the design of the system is simple.

5.Systems can be dedicated to produce particular bottle sizes. A short operator-training period due to the simplicity of the design.

6.Maintenance costs are kept to a minimum

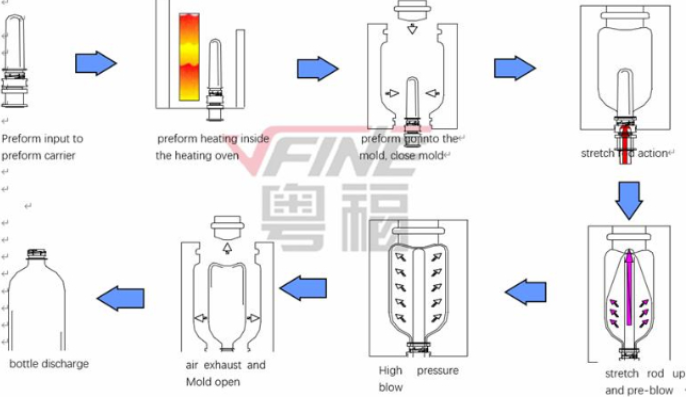

How does the machine work?

1. The machine is fully automatic, and after adjusting the settings, no one needs to operate it continuously.

2. The bottle making process starts by loading preforms into the preheater.

3. The preheater uses a variable speed track that moves the preforms through a heating tunnel. The heat tunnel has specially designed heating elements for a consistent heating operation with minimal maintenance.

4. When the preforms have made one "trip" through the preheater, they are manually loaded two(three or four) at a time into the blow molder.

5. After the bottles are formed in the blowing cycle, they are removed and the cycle continues. The finished bottles are then loaded directly onto a conveyor for filling or can be stored for later use.

Factory Pictures

Zhongshan chumful machinery co ltd is the one branch of Zhongshan Vfine machinery co ltd, which is a professional manufacturer of PET bottle blowing machines, that integrates the R&D, production, and sales. Since the development and design of the first generation linear automatic stretch blow molding machine, Vfine's technical team has focused in the PET market for 20 years. We've successfully supplied machines to many world-famous brands. Not only the bottle blowing machine,Vfine(CHUMFUL) also provide the turnkey plant service for all customers, we can offer from A to Z solution for all kind of PET bottle production, PET bottle water, and pet bottle beverage.

About Installation

We have a professional after-sale service team, before the machine arrive, we will give consulting service about the machine's place, electricity, and water preparation works. after the machine arrives in the customer's factory, we also send the engineer for installation and make training for the customer's engineer, customer should take charge of the engineer's travel cost, board and lodging , and labor cost.

All the machines ship from vfine machinery, are well tested and with no less than 72hours continous running, and at least 1 hour continous production test, which make sure that, all the equipments can be quickly make production in customer's factory.

we guarantee that, all the machine can finish installation and start production with 2days since our engineer commission, under the condition that the customer workshop meets the installation conditions.

During commission time, our engineer will make training for customer technician and workers, make sure that, the machine will be correct operated.

Packaging&Shipping

|  |  |

|  |  |