Automatic 10-cavity Pet Bottle Blow Molding Machine

Product advantages

The Automatic 10-cavity Pet Bottle Blow Molding Machine offers exceptional efficiency and productivity with its high-speed production capabilities, allowing for the creation of up to 10 bottles simultaneously. This innovative machine also features advanced technology to ensure consistent quality and precision in the manufacturing process. Its user-friendly design and easy operation make it the ideal choice for businesses looking to streamline their production processes and meet increasing demands in the market.

Company profile

With a focus on innovation and quality, our company specializes in manufacturing state-of-the-art automatic 10-cavity Pet Bottle Blow Molding Machines. Our commitment to excellence is reflected in our cutting-edge technology and precision engineering, ensuring superior performance and reliability. We take pride in delivering high-quality products that meet the needs of our customers while also reducing environmental impact through sustainable production practices. With a dedicated team of experts and a strong emphasis on customer satisfaction, we strive to be a trusted partner for businesses looking to elevate their packaging operations. Experience the difference with our industry-leading solutions.

Enterprise core strength

With over 10 years of experience in the manufacturing industry, our company is a leading provider of high-quality automatic 10-cavity Pet Bottle Blow Molding Machines. We are committed to delivering cutting-edge technology and innovative solutions to meet the ever-evolving needs of our customers. Our machines are designed for maximum efficiency, productivity, and reliability, allowing you to produce top-quality Pet bottles with ease. We take pride in our dedication to customer satisfaction and our relentless pursuit of excellence in all aspects of our business. Trust us to provide you with the best-in-class machines that will help take your production to the next level.

At present, the basic rules of design in our company are to keep customer-oriented and industry-driven. Our Fully Automatic Pet Bottle 6 10 Cavity Blow Molding Machine Machines Making Plastic Moulding Manufacturing Molder Manufacturers Price Cost Machineryhas a look that is unique enough to grab the attention of most of the customers. Moreover, it has the tested performance and so on. These aspects can prove the value of the product. We can provide you with the highest quality products within your budget. The specifications of Fully Automatic Pet Bottle 6 10 Cavity Blow Molding Machine Machines Making Plastic Moulding Manufacturing Molder Manufacturers Price Cost Machinery can be customized according to your needs.

| Model NO. | YF-L10E | Making Method of Parison | Stretch Blow |

| Automation | Automatic | Computerized | Computerized |

| Certification | CE, ISO9001:2008 | After-sales Service | Includes |

| Product | Bottle Making Machine | Item | Bottle Making Machine Price |

| Item 3 | Pet Bottle Machinery | Item 4 | Pet Bottle Machinery Price |

| Transport Package | Wooden | Specification | 7m*2m*2.5m(l*w*h) |

| Trademark | vfine | Origin | China |

| HS Code | 8477109000 | Production Capacity | 50-100set/Year |

| Package size per unit product | 700.00cm * 200.00cm * 230.00cm | Gross weight per unit product | 9000.000kg |

Product Description

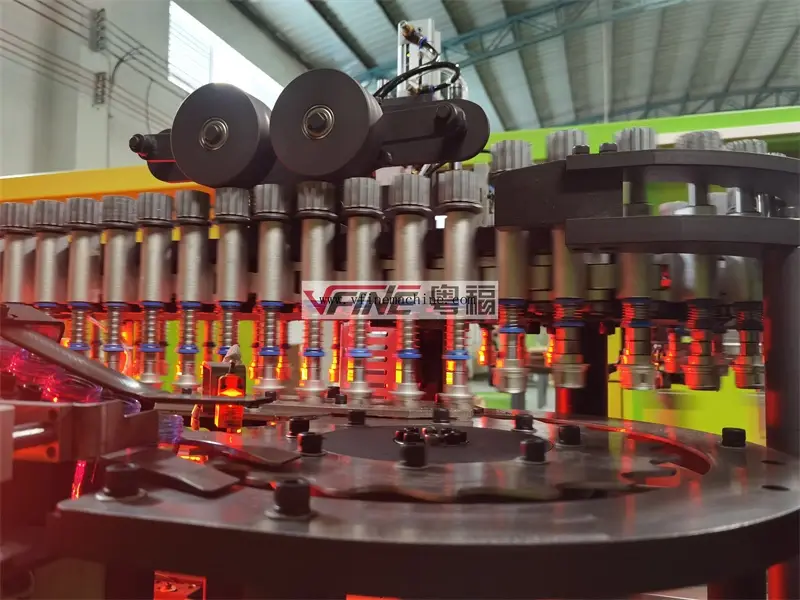

10-cavity, full servo fully automatic stretch blowing molding machine

machine Output: 18000bph

Max. Volume: 50ml -2 L

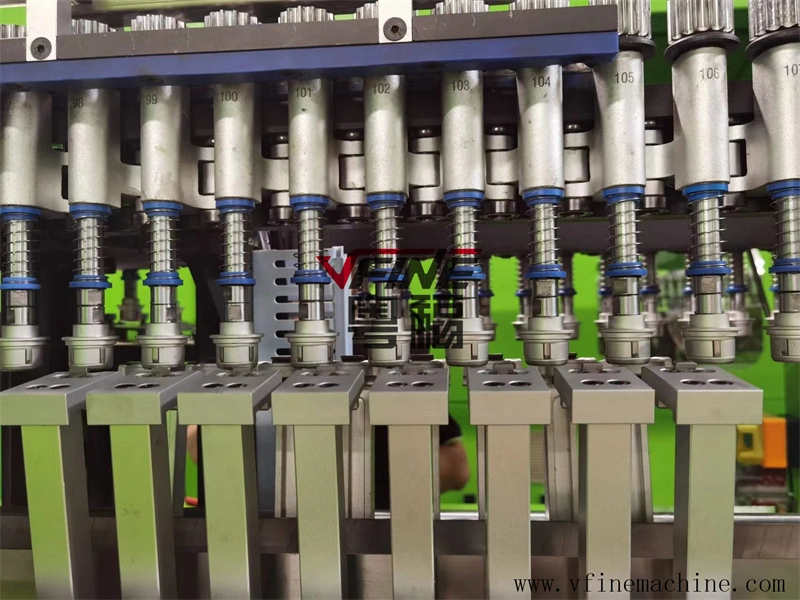

Full servo control for preform infeed, preform transfer, variable pitch, molding, stretching

No need low pressure air for the blowing machine

(2)application scope

Suitable for producing PET water bottle, carbonate bottle, middle temperature filling bottle, medicine bottle, cosmetic bottle, cooking oil bottle etc.

advantage of L-series Vfine blowing machine

save energy :

The preform heating and blowing are on separated section, so that it can save the waiting time of each unit. The preforms are heated intensively, as the rotary machine heating type, improve the heating efficiency. Meanwhile, the high pressure air can saved by air recycling system, for the pre-blow or low pressure air supply, save energy.

Save space:

The infeeding system is inside the machine, the heating structure save the preform pitch distance, save the space.

high efficiency:

We improve about 30% output, in the situation of low down the machine energy consumption, improve the overall energy utilization.

Infeeding system:

The infeeding system is in single channel with less sensors for better infeeding.

Heating system:

Preforms are heated intensively, the cooling device and the cross ventilation protect the preform neck from out of shape, improve the energy utilization, and heating efficiency.

Transfer unit:

The variable pitch device is controlled by servo for stable and accurate transferring.

Clamping unit:

The clamping unit is controlled by servo motor to ensure the synchronization, stable running and precise location.

High pressure air recycle system:

The high pressure air recycle system save the high pressure to the tank, reduce the noise and save energy lost.

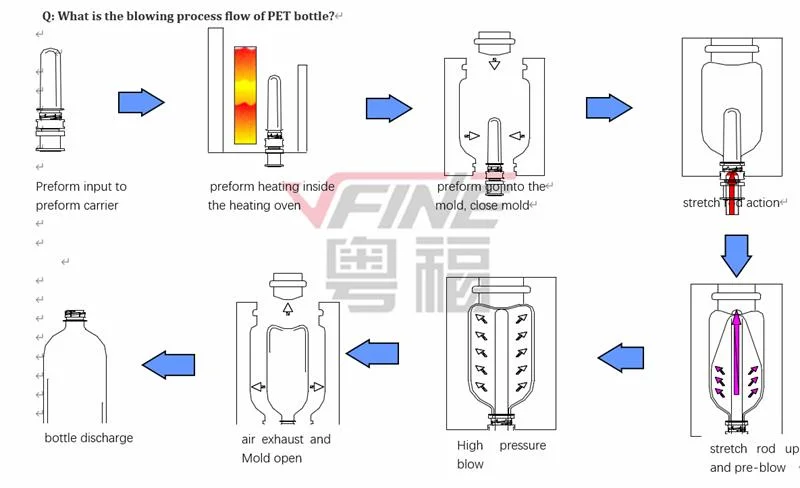

PET bottle blowing process flow chart

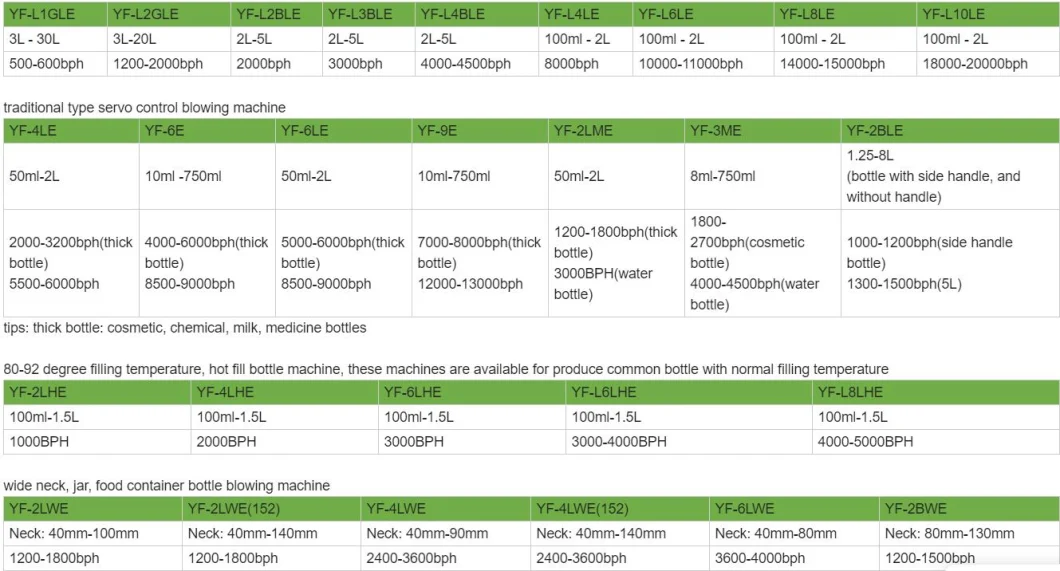

| MODEL | YF-L10LE |

| Bottle Volumn | 50-2000ml |

| Cavity number | 10 cavities |

| output | 18000-20000BPH |

| Machine size | 6700*2000*2500 |

| bottle type | all kinds of PET bottle, size from 50ml-2000ml |

| low pressure air | no need |

| high pressure air | 18000ltr/min |

| air pressure | 35kg |

| Machine weight | 9000kg |

We have a professtional after-sale service team, before machine arrive, we will give consulting service about the machine place, eletricity, and water prepare works. after machine arrive in customer factory, we also send engineer for installation, and make training for customer's engineer, customer should take charge of the engineer travel cost, board and lodging and labor cost.

* More 20year experience in PET bottle blowing and package.

* Professional manufacturer of high quality PET machine.

* Consultor of complete line service for PET bottle equipments.

* Provide professional Productor design

zhongshan vfine machinery co ltd

zhongshan Chumful machinery co ltd

website: vfine88.en.made-in-china.com