High Speed 3-Cavity Full Servo Bottle Making Machine

Product features

The High Speed 3-Cavity Full Servo Bottle Making Machine by Vfine offers energy-efficient and flexible operation with a production capacity of 3000-3500BPH. With a drawer-type mold locking structure, mold change can be done quickly in less than 30 minutes. The intelligent control system allows for easy parameter settings and troubleshooting on the touch screen, ensuring stable performance and low maintenance costs. This plastic water bottle manufacturing machine price promises high efficiency, fast mold change, and reliable performance for bottle production needs.

We serve

At our company, we serve with our High Speed 3-Cavity Full Servo Bottle Making Machine, designed to meet your production needs seamlessly. Our machine offers unmatched efficiency and precision, allowing you to increase productivity while maintaining high-quality standards. We understand the importance of delivering reliable and innovative solutions to our clients, which is why our full servo bottle making machine is built with cutting-edge technology and superior craftsmanship. With our dedication to serving you with excellence, you can trust that our product will exceed your expectations and elevate your manufacturing capabilities. Choose us for a seamless and efficient production process.

Why choose us

At High Speed Solutions, we serve customers with the latest technology in the form of our 3-Cavity Full Servo Bottle Making Machine. With our commitment to innovation and quality, we offer a seamless production experience for businesses looking to maximize efficiency and output. Our machine is designed to provide high-speed operation and precise control, resulting in consistent and high-quality finished products. Additionally, our dedicated customer service team is always available to assist with any inquiries or technical support needs. Trust High Speed Solutions to serve your production needs with excellence and reliability.

Product Introduction

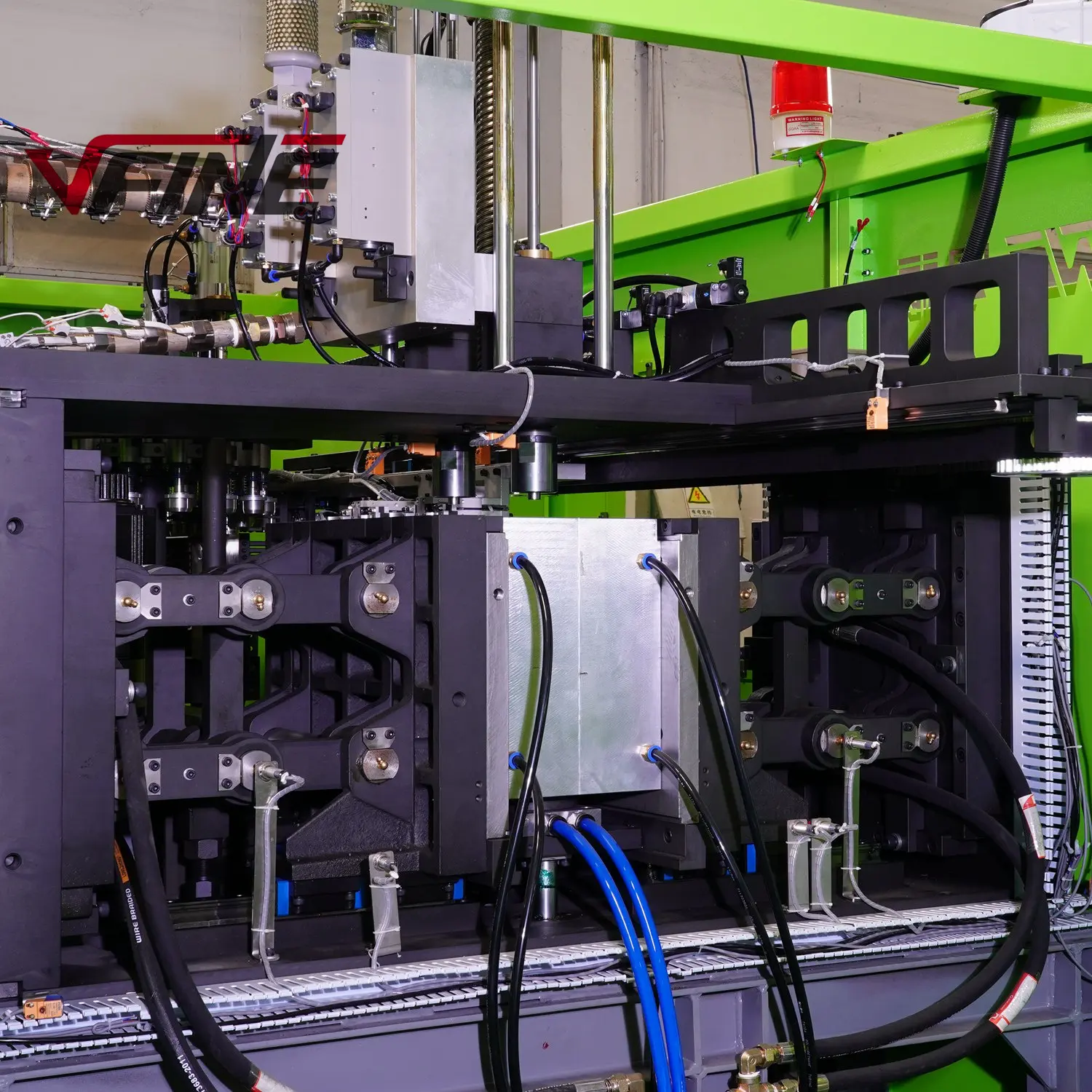

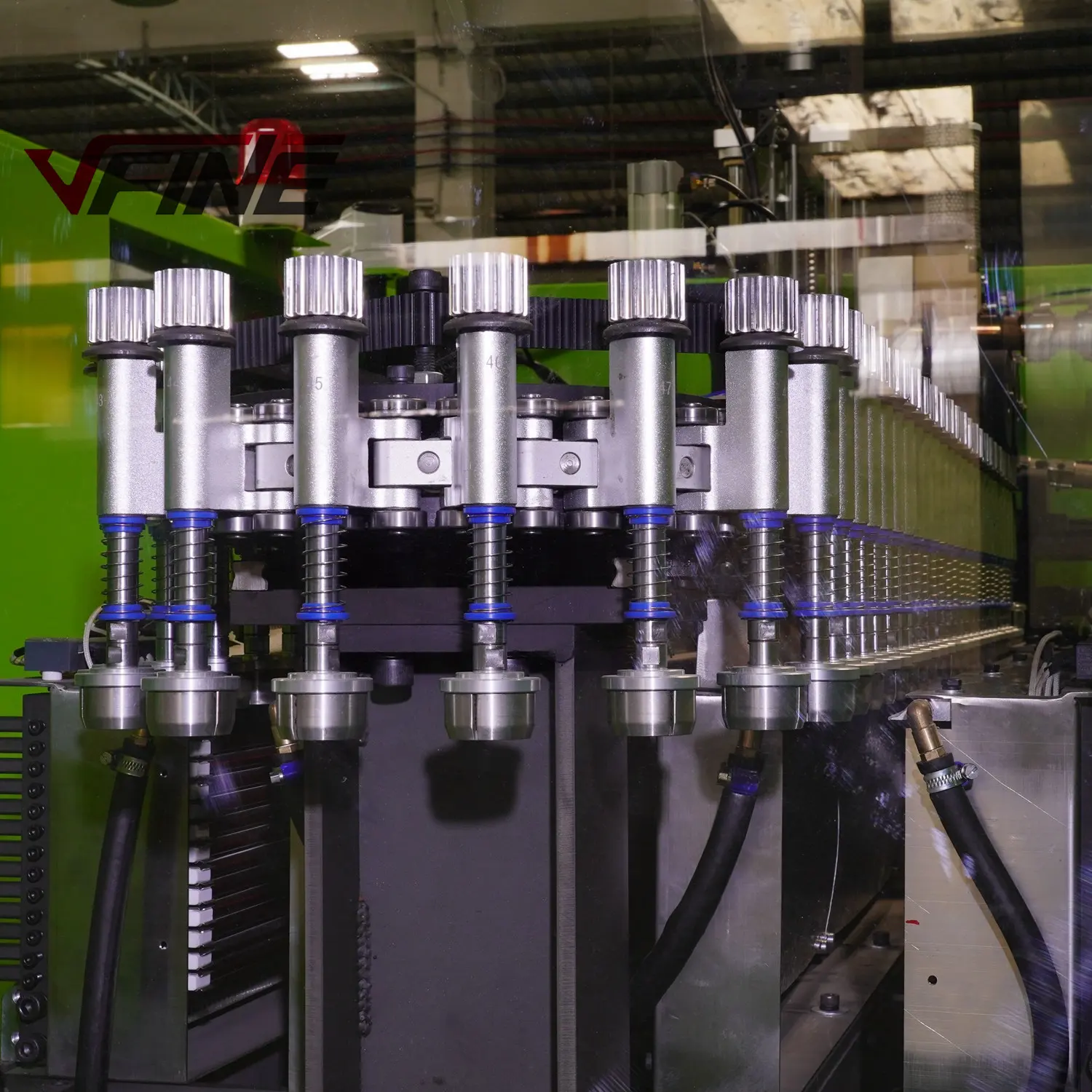

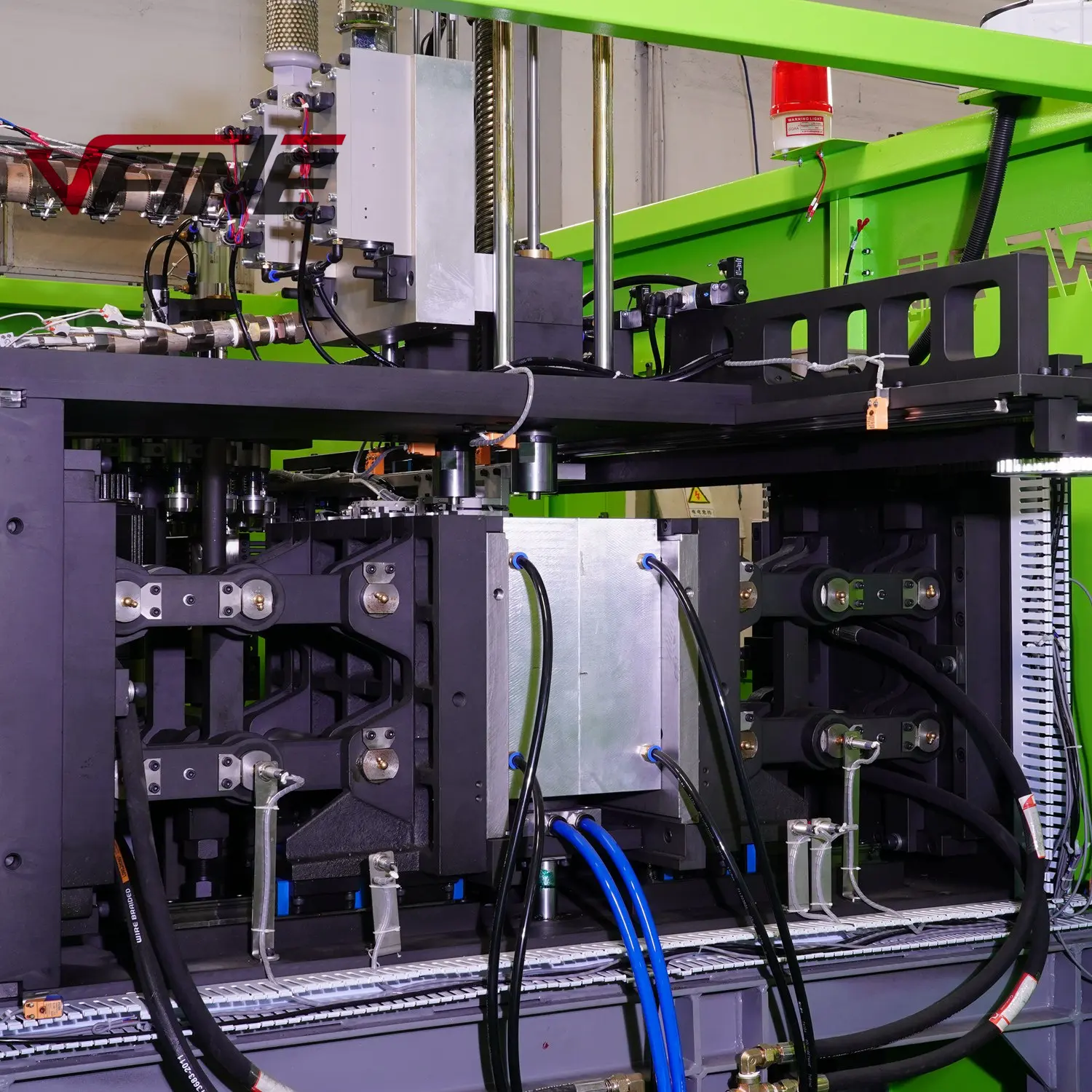

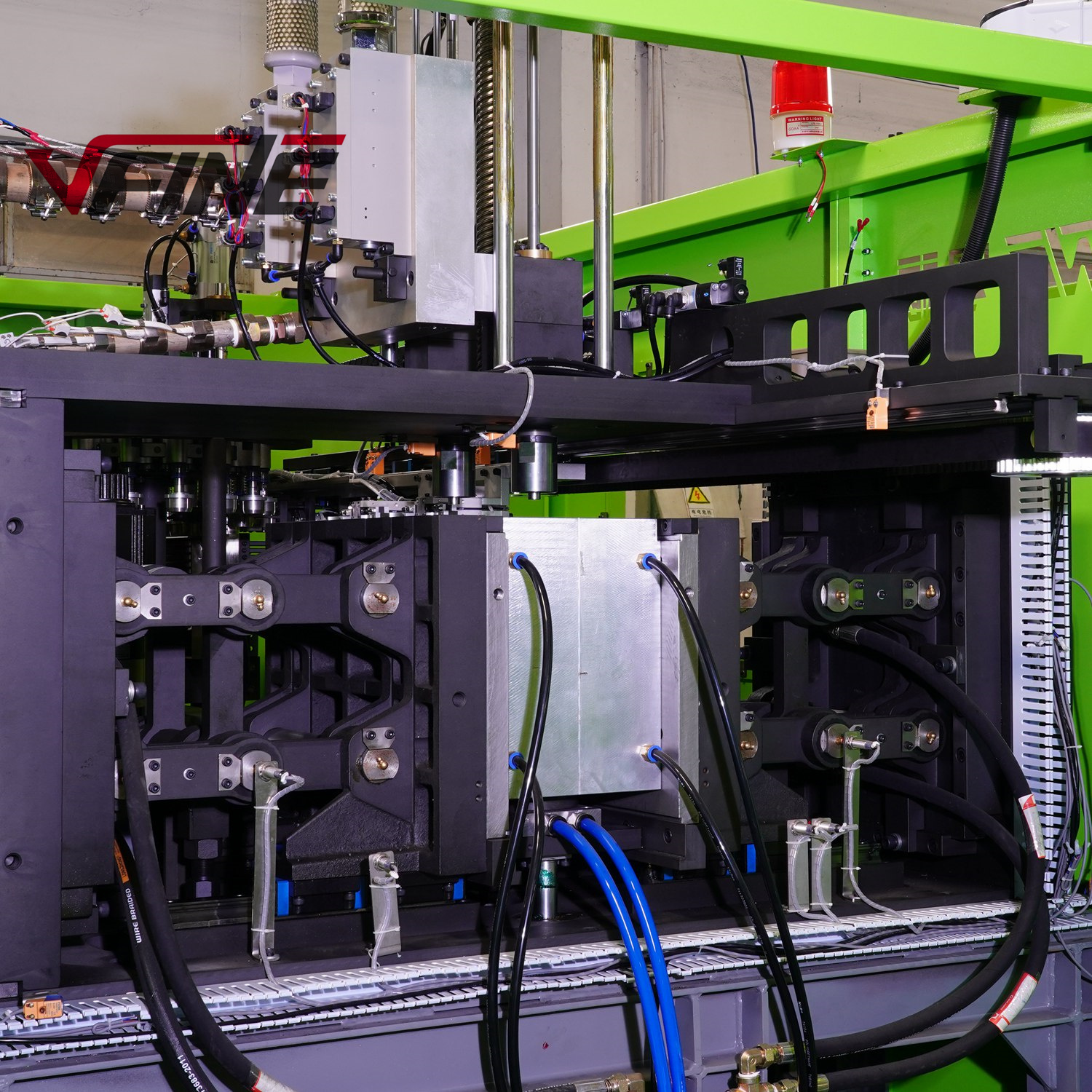

machine detail

| item | |

|---|---|

| Machine model | YF-L3GLE |

| machine output | 3000-3500BPH |

| cavity number | 3 |

| bottle capacity | 3L-10L |

| machine weight | 7500Kg |

| machine size | 6700*1950*2500(mm) |

| machine voltage | customized |

pet bottle process steps

pre-blow,high pressure blow

and stretch rod up

vfine bottle making machine advantages

Ø Energy efficient, flexible

The single chamber production capacity of the equipment is not less than 2000 bottles/hour, and the efficiency is high; the equipment combines the advantages of the rotary machine and the linear machine, with a high energy utilization rate and simple and convenient operation

Ø Fast mold change

Drawer-type mold locking structure, easy and quick mold change, no more than 30 minutes to change the mold

Ø Intelligent control system, which can complete all parameter settings, equipment operation, and troubleshooting on the touch screen.

Ø Stable equipment performance and low maintenance cost

Ø Oil-free preform transfer system, there is no risk of preform getting polluted

Ø The equipment structure design is compact, occupying a small space

Ø Powerful temperature control system can ensure constant heating output and ensure the stability of preform heating

Ø The whole machine frame and clamping plates are annealed, and the plane and hole processing are completed at one time in the CNC machining center to ensure that the machine frame and template are accurate, non-deformed, and durable.

Ø Powerful cooling system to ensure that the thin-walled preform neck bottles and light-weight bottles are not deformed.

Company Advantages

1. Vfine is a professional manufacturer dedicated to high-quality automatic blow molding machines, and its products are positioned in the mid-end and high-end markets.

2. With more than 20 years of experience in the bottle making and packaging industry, Vfine has provided services for many first well-known brands in the industry.

3. Vfine has a strong R & D design, production, after-sales service team and experienced sales consultant team

4. Possess strong bottling complete line planning ability and rich whole line implementation ability

5. Vfine has four-high and two-low products: high quality, High value-added, high cost-effective, and high durability; Low energy cost, and low maintenance cost.