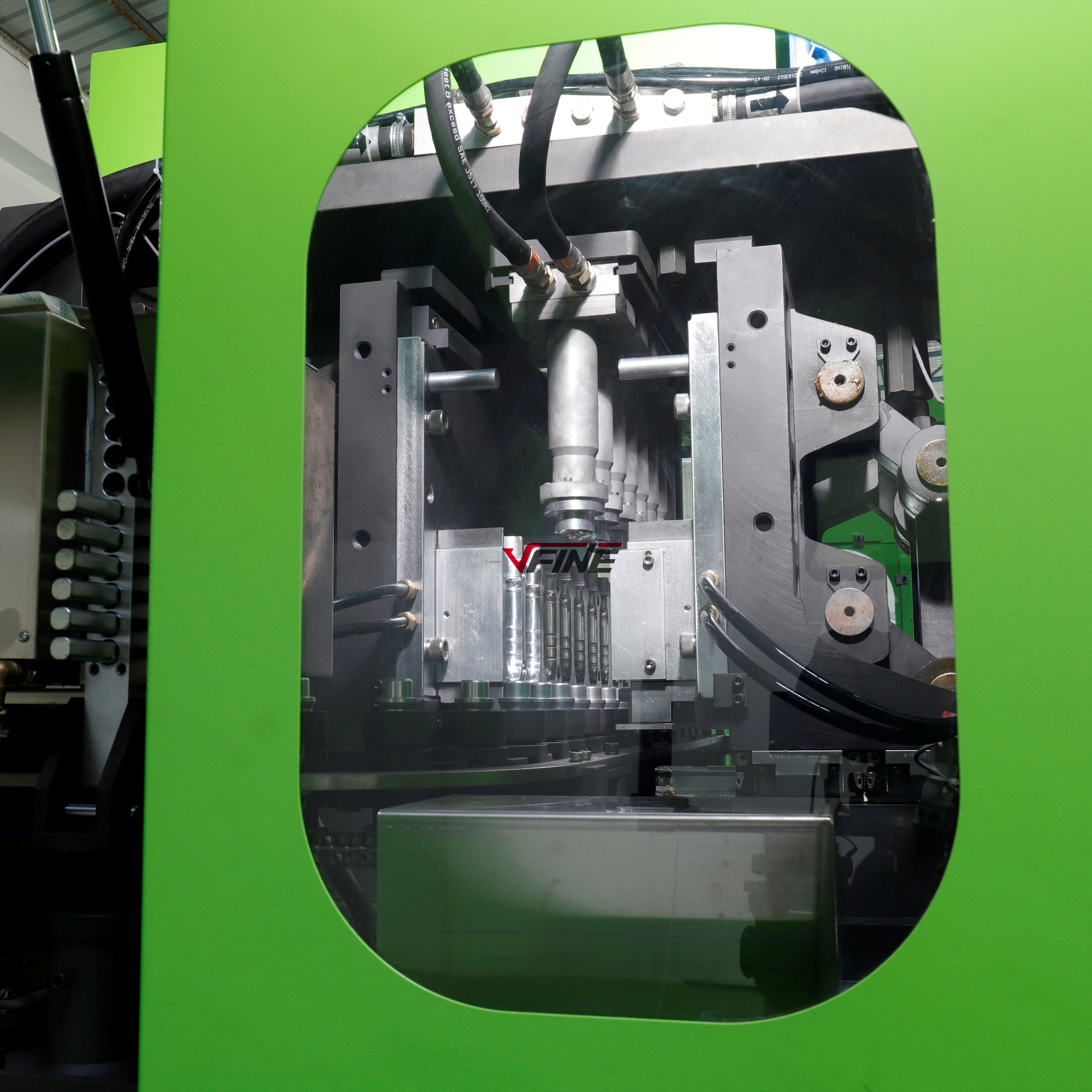

9cavity blow molding machine

Auto 9cavity Bottle Blowing Molding Machine 12000-13000BPH High Speed Making Pure Mineral Water Beverage Dairy Washing Liquid Wine Condiment Edible Oil Juice Milk Shampoo Container Plastic Pet Bottles

| Item | YF-9E |

| Cavity Number | 9 |

| Machine Output | 12000-13000bph |

| Max Volumn | 0.75L |

| Weight of Machine | 8 Tons |

| Size of the Machine(L*W*H) | 5.5x2.15x2.5 |

9-cavity, linear stretch blowing molding machine

Output: 12000-13000bph

Max. Volume: 0.75L

(2)application scope

Full automatic blow molding machine is suitable for producing PETplastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle cooking oil bottle, chemical product container, cosmetics bottles etc.

|

|

|

|

|

1.1 New Auto Preform Unscrambler System.

*Adopts one-way preform-feeding structure and preform-separating by servo motor structure which solve the preform block and abrasion problem.

*There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

1.2 New Heating System.

*Perfect heating system design decrease power consumption.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted from screen.

*Cycling water-cooling system keeps the oven temperature constantly.

1.3 The Application Of Servo System On Main Transmission.

The transmission adopts servomotor for positioning that can orientate the preform-heating base quickly, accurately and steadily when the machine starts and running.

1.4 Servo Technology Innovation On Clamping System & Stretching.

*Adopts servo motor to drive the two cranks to control the clamping system which can shorten the mold-clamping time and improve productivity, and also solve the swelling mold and big joint line problem with the effect of pressurize plate.

* Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

1.5 Easy To Change Bottle Shape.

*Drawer type mold structure design is easy for mold changing. Within 30minutes can change a mold on the condition of same bottleneck diameter.

1.6 Intelligent Human-Machine Interface.

*Human-machine interface control, easy operate and monitor.

*Live production information supervise, auto record production data everyday

*Failure warning and troubleshooting.

|

|

|

Factory Pictures

Zhongshan chumful machinery co ltd is the one branch of Zhongshan Vfine machinery co ltd, which is a professional manufacturer of PET bottle blowing machines, that integrates the R&D, production, and sales. Since the development and design of the first generation linear automatic stretch blow molding machine, Vfine's technical team has focused in the PET market for 20 years. We've successfully supplied machines to many world-famous brands. Not only the bottle blowing machine,Vfine(CHUMFUL) also provide the turnkey plant service for all customers, we can offer from A to Z solution for all kind of PET bottle production, PET bottle water, and pet bottle beverage.

Company Advantages

Pre-Sales Service

* Inquiry and consulting support.

* Free product design.

* Visit our Factory.

Warranty

* The machine and mold guarantee for one year with repair/ free replacement of defective parts.

* Spare parts of machine components, mold components and tools are shipped along with the machine.

After-Sales Service

* Our company wants to make sure you are getting the very best out of the machine and mold. After delivery, we will send our engineer to your plant to train your staff how to use the machine well, until we get approval by the customer.

* Remote assistance to help you solve problems in case of machine system failure.

Packaging&Shipping

|  |  |

|  |  |