5L-20L Plastic PET Bottles Blowing Machine

machine high light

1. Fully automatic, full-servo, high-speed, high quality bottle blow molding machine,

2. the production capacity is at least 2400bph

3. Smart mold design, can quickly change the mold within 30 minutes.

4. Intelligent design, pull rod equipment, heating parameter setting, blowing parameter and speed setting can all be completed on the operation screen.

5. Durable machine, low energy cost, Low maintenance cost

6. Application scope: PET bottle for water, Juice, soda, Ice tea, CSD, beer, wine, milk, consident, cooking oil, soy sauce, etc.

| Model | YF-L2GLE |

| Bottle Volumn | 5L-20L |

| Output | 1200-1500bph for 20l 2000-2400bph for 5l |

| Machine Size | 5500*2050*2500mm |

| Machine Weight | 6000kg |

2-cavity, linear stretch blowing molding machine

Output: 1200-1500bph

PET bottle Volume range: 5L-20L

(2)application scope

Suitable for producing PET water bottle, PET jar, edible oil PET bottle etc. This model pet blowing machine is designed for big volume specified bottle.

1. multiple time use PET 5 gallon tank

2. one time use 5L- 20L water tank, edible oil container

3. 5L - 20L beer tank

4. 5L - 20L wine tank

5. 5L - 20L stackable Cooking oil bottle

6. shrinkable cooking oil bottle

|

|

|

|

|

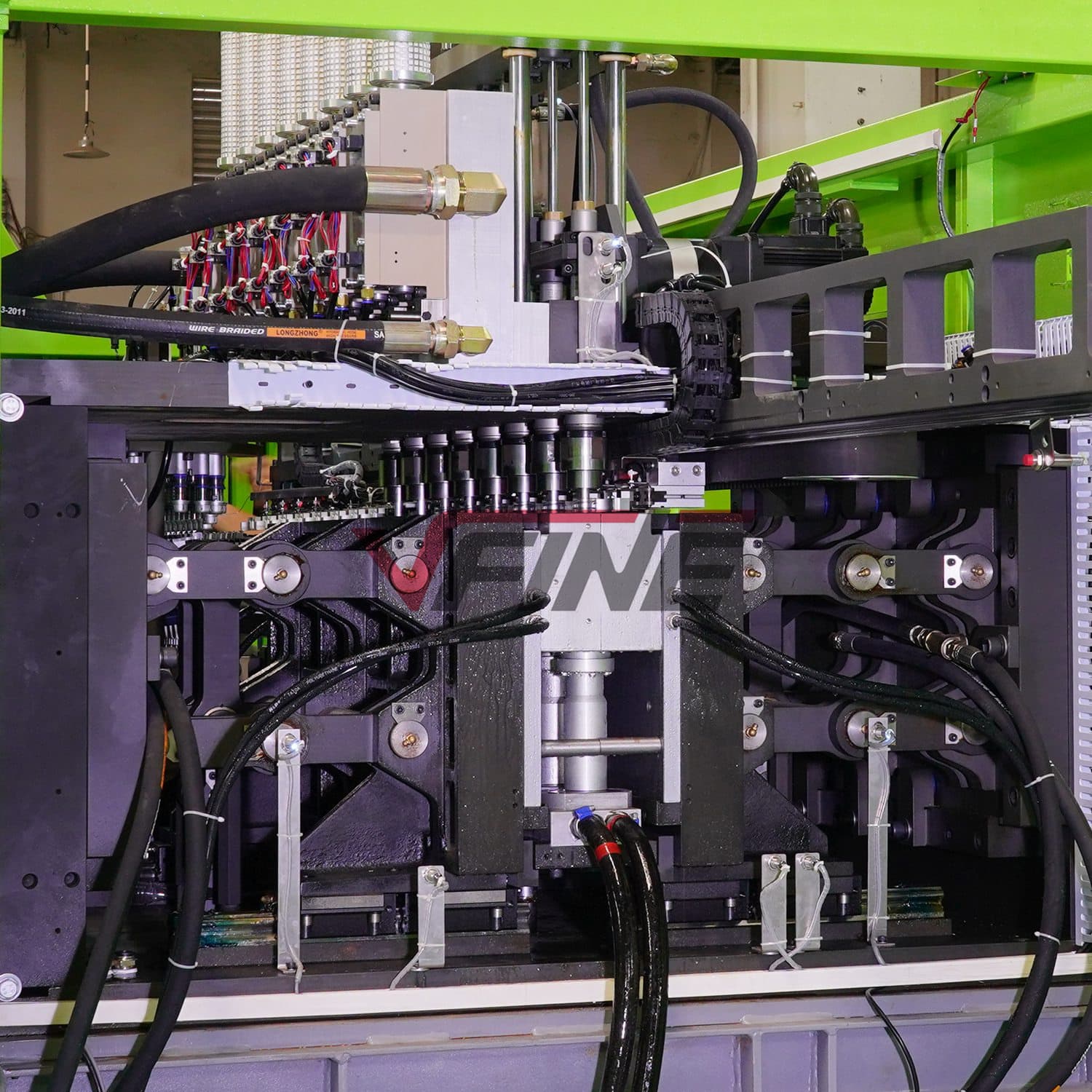

Features of main blowing machine:

1). Stable performance with advanced PLC.

2). Automatic preform conveyer to save human cost.

3). Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4). High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

5). High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6). Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

7). Strong clamping force with high pressure and double crank links to lock the mold.

8). Two ways of operating: automatic and manual.

9). Low cost, high efficiency, easy operation and maintenance etc., profited from the fully automatic technological process.

10). Ideal cooling system make the finished bottles without any flaws.

|

|

|

Advantages of VFINE Blowing Machine:

Save energy:

The preform heating and blowing are on separated section, the process of each unit are without time waste by each unit waiting for each other. The preforms are heated intensively, as the rotary machine heating type, improve the heating efficiency. Meanwhile, the high pressure air can saved by air recycling system, for the pre-blow or low pressure air supply, save energy.

High efficiency:

We improve about 20% output, meanwhile low down the machine energy consumption, improve the overall energy utilization.

Preform Infeeding system:

The preform infeeding system is in single channel with less sensors for better infeeding.

The preform infeeding system is inside the machine, reduce machine configuration space.

Heating system:

Preforms are heated intensively, the cooling device and the cross ventilation protect the preform neck from out of shape, improve the energy utilization, and heating efficiency.

The heating oven outsize part can be turn over, it is easy to change the heating lamps.

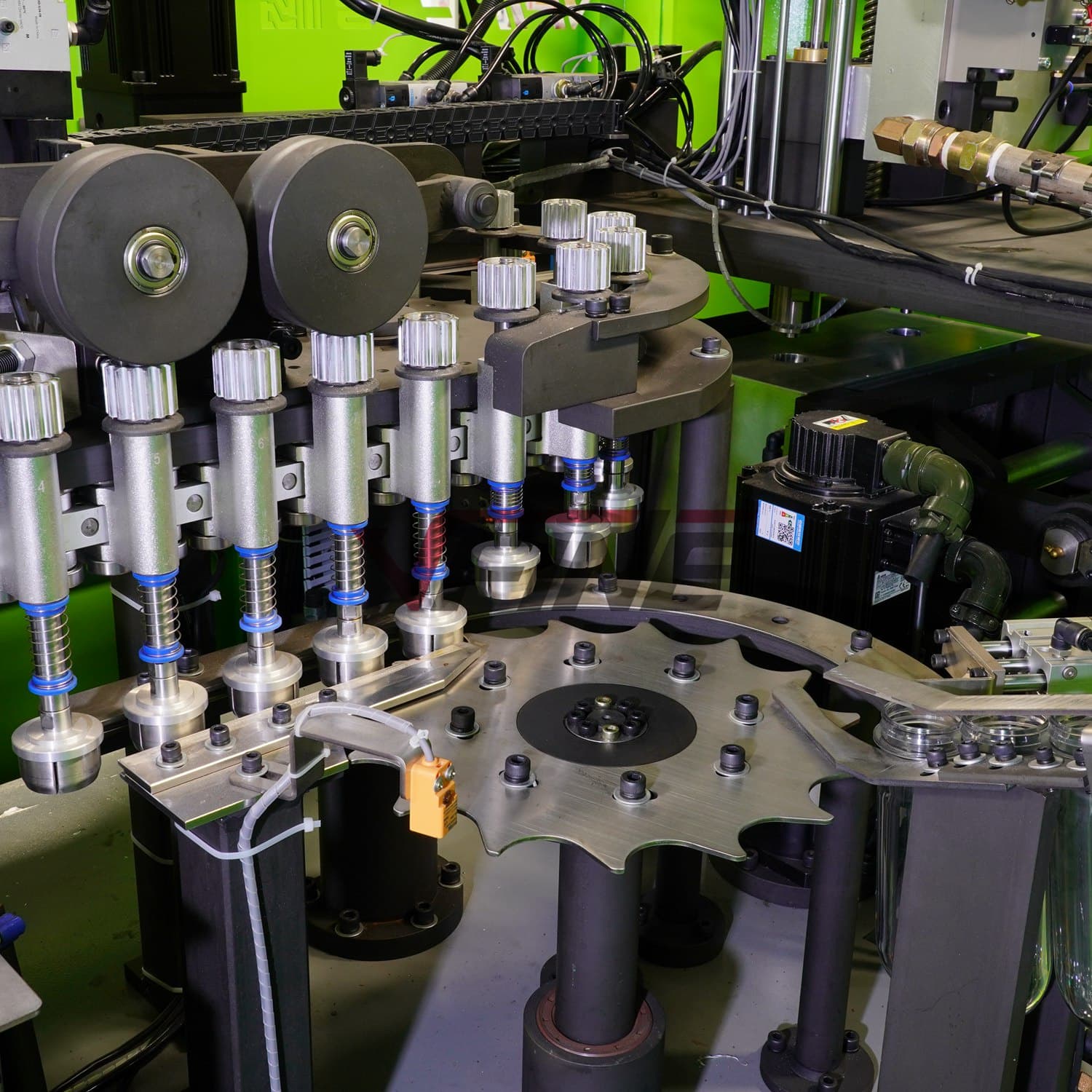

Transfer unit:

The variable pitch device is controlled by servo for stable and accurate transferring.

Clamping unit:

The clamping unit is controlled by servo motor to ensure the synchronization, stable running and precise location.

References&Certifications:

Factory Pictures

Zhongshan chumful machinery co ltd is the one branch of Zhongshan Vfine machinery co ltd, which is a professional manufacturer of PET bottle blowing machines, that integrates the R&D, production, and sales. Since the development and design of the first generation linear automatic stretch blow molding machine, Vfine's technical team has focused in the PET market for 20 years. We've successfully supplied machines to many world-famous brands. Not only the bottle blowing machine,Vfine(CHUMFUL) also provide the turnkey plant service for all customers, we can offer from A to Z solution for all kind of PET bottle production, PET bottle water, and pet bottle beverage.

Company Advantages

VFINE Machinery has been keeping good cooperative relationship with customers since our establishing.

The satisfaction of our customers is the pursuit of every member of Vfine Machinery, the only way we service in the competitive market is to help our customers to full fill their requirement.

Vfine sales consultant

1. We can provide comprehensive and professional Suggestions on equipment selection.

2. Energy consumption calculation and investment income analysis can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product optimization Suggestions.

4. The stretch plastic bottle blow molding machine has remote maintenance function

Advantages of Vfine tech teams

1. More than 800 sets of customized machines in the market enable us to have rich experience across multiple industries.

2. Customize equipment models according to customer product characteristics.

3. Project responsibility system, closed-loop team cooperation between the design team and the process team, adjustment of the team, and joint creation of equipment that users are satisfied with.

4. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry.

5. Undertake a number of large projects, and has a group of senior technical personnel composed of the construction team, can build cable bridge, installation of a complete set of equipment.

Advantages of Vfine Machinery after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment.

5. Free training for customer technician while making installation

6. Special processing equipment to produce after-sales accessories to ensure rapid response to user needs.

After Sale Service

1. During installation service time, we provide technician training for all customers

2. We provide all day long phonecall or online service for all customers if customer face any problem on machine

3. The most outstanding point is, high quanlity machine let customer very low maintenance cost for long time use of the machine

Packaging&Shipping

|  |  |

|  |  |