Small Capacity Automatic Bottle Blowing Machine

machine high light

1. Fully automatic, full-servo, high-speed, high quality bottle blow molding machine,

2. the production capacity is at least 6000bph

3. Smart mold design, can quickly change the mold within 30 minutes.

4. Intelligent design, pull rod equipment, heating parameter setting, blowing parameter and speed setting can all be completed on the operation screen.

5. Durable machine, low energy cost, Low maintenance cost

6. Application scope: PET bottle for water, Juice, soda, Ice tea, CSD, beer, wine, milk, consident, cooking oil, soy sauce, etc.

| Model | YF-4LE |

| Max Bottle Volumn | 3500ml |

| Cavity Number | 4 |

| Output | 5500-6000BPH |

| Machine Size | 4000*2000*2500mm |

| Machine Weight | 6500kg |

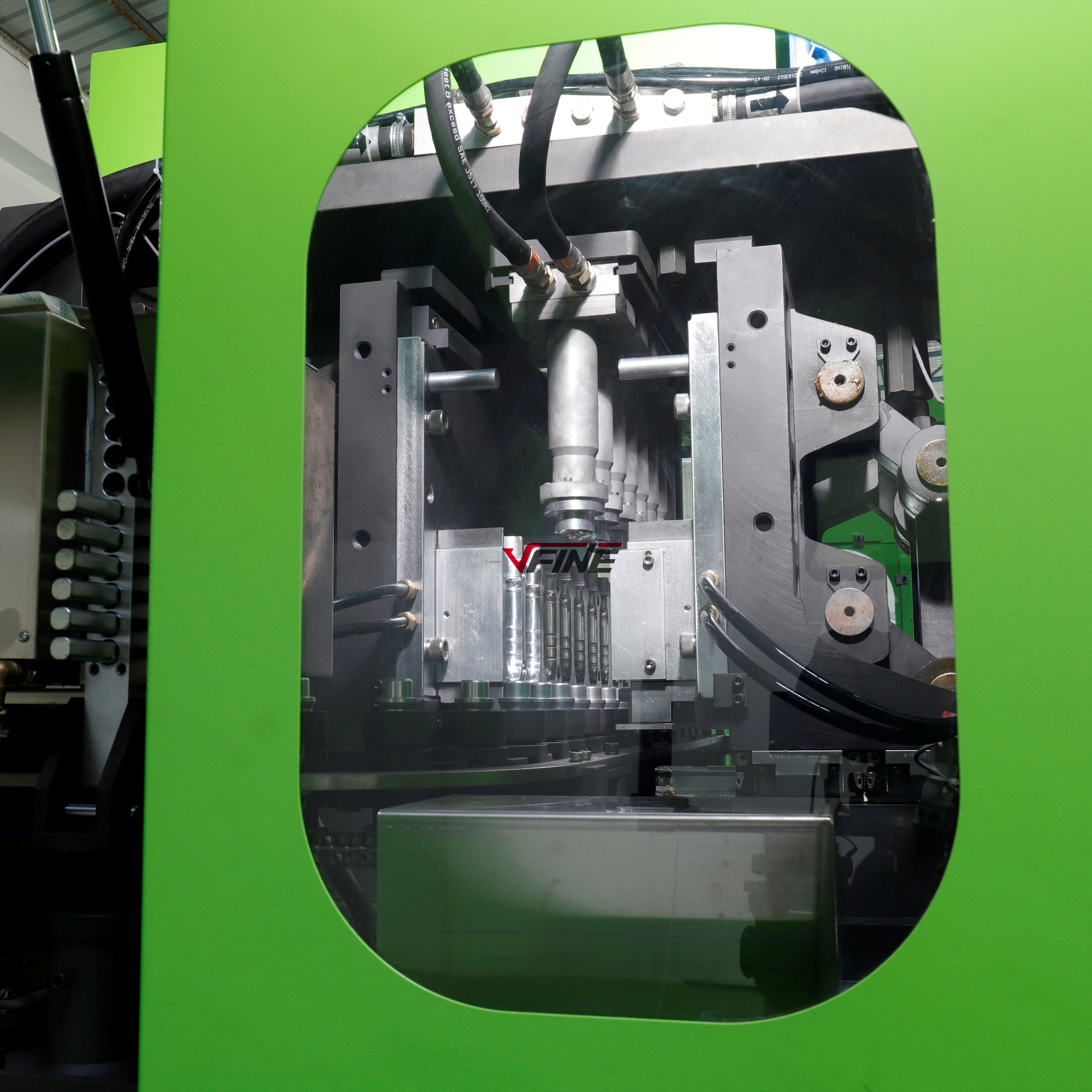

4-cavity, linear stretch blowing molding machine

Output: 6000bph

Max. Volume: 3.5L

(2) Application:

Automatic PET Bottle Blowing Machine is suitable for blowing PET bottles of various shapes, volume from 10ml to 3500 ml, wide application for blowing mineral water bottles, soda bottles,cola bottles,etc.

|

|

(3) Advantages:

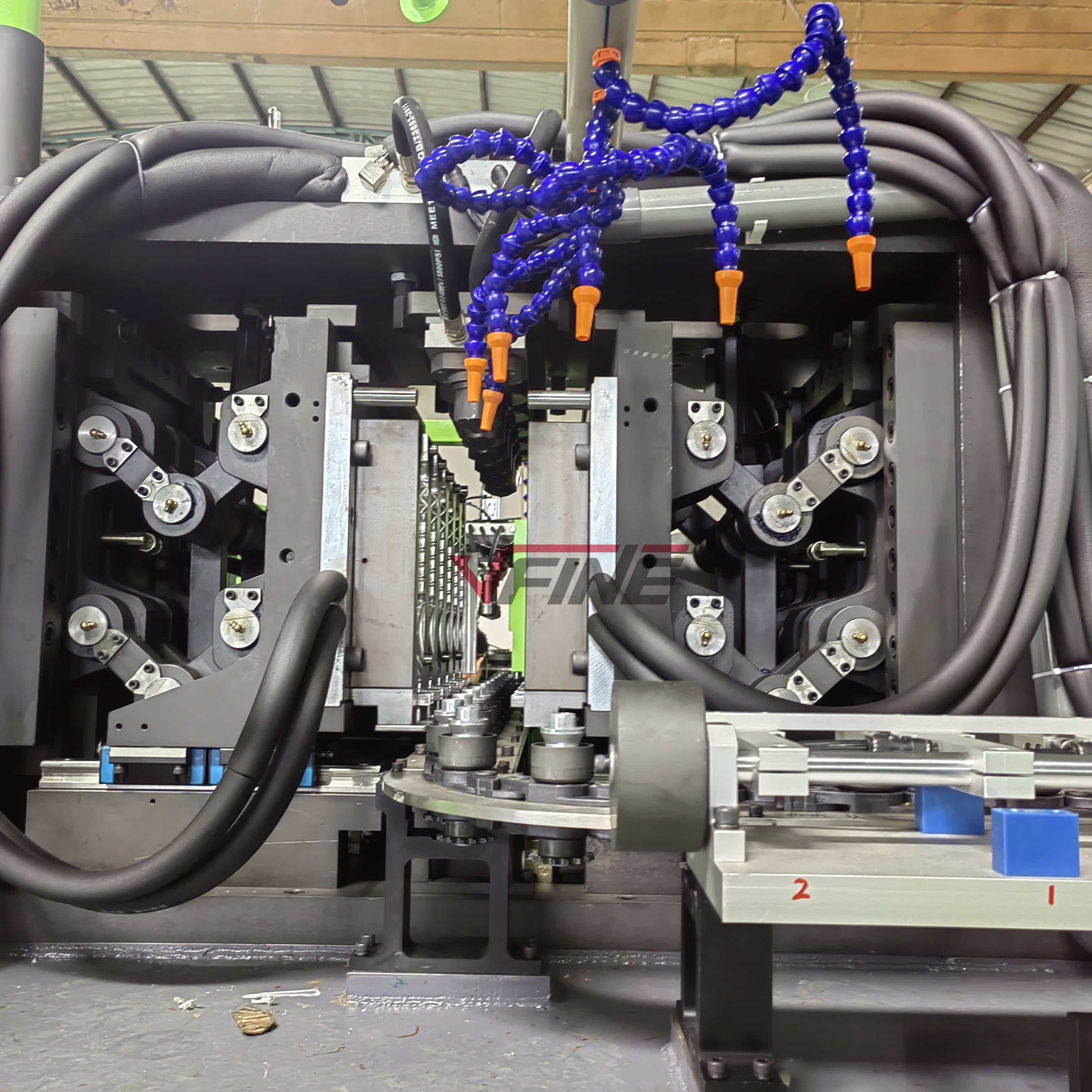

1.New double crank four pull-up bar clamping structure, cross balance fixed slide.

2.Sealing, stretch adapts parallel bars design, combined, good for products molding.

3.Programmable PLC controller automatically control, microcomputer touch screen convenient operation.

4.Bottle embryo heated by infrared, controllable constant pressure control, so as to achieve the best blowing precision.

Product Details

|

|

|

Features of main blowing machine:

1.1 New Auto Preform Unscrambler System

Adopts one-way preform-feeding structure and preform-separating by servo motor structure which solve the preform block and abrasion problem.

*There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

1.2 New Heating System

*Perfect heating system design decrease power consumption.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

1.3 The Application Of Servo System On Main Transmission

The transmission adopts servomotor for positioning that can orientate the preform-heating base quickly, accurately and steadily when the machine starts and running.

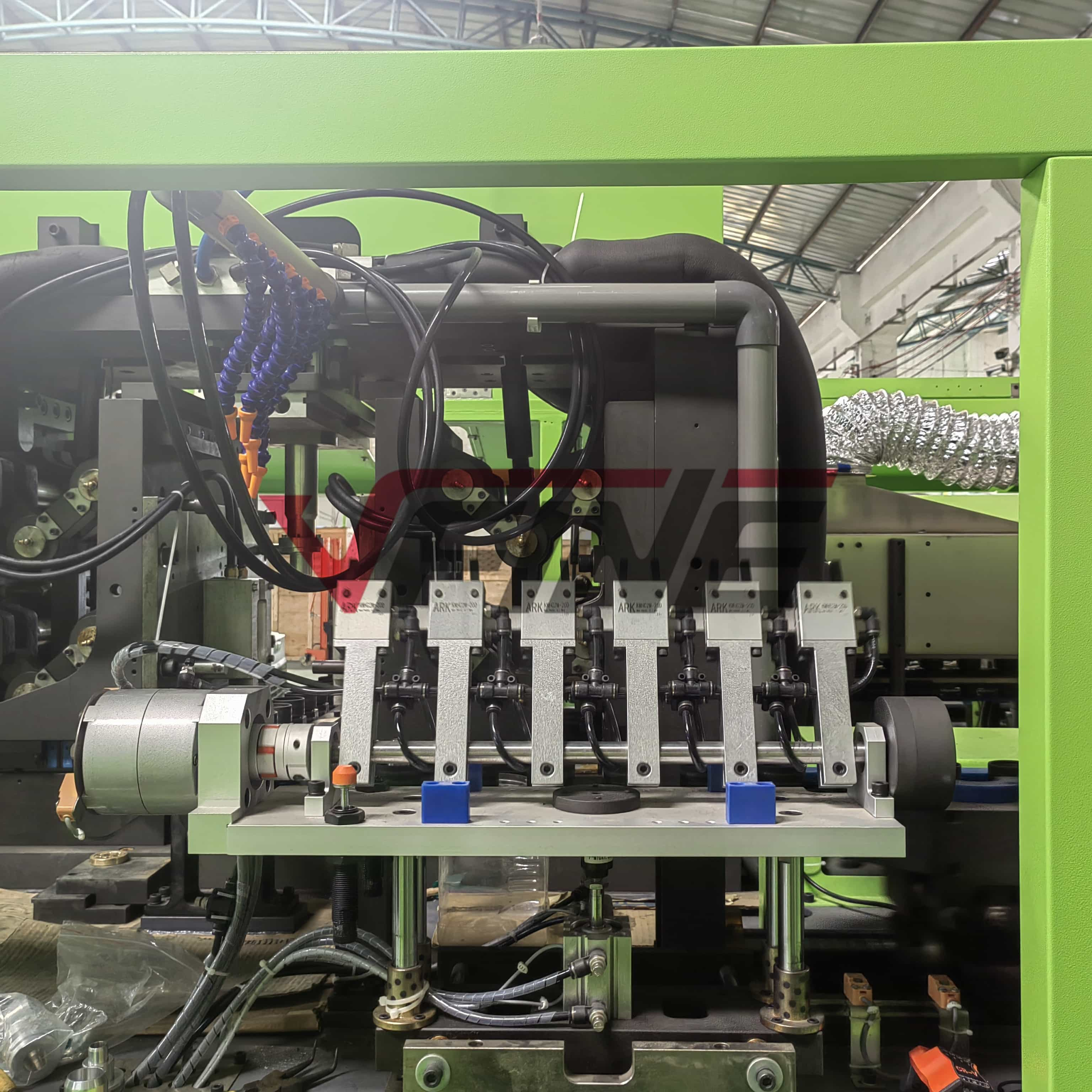

1.4 Servo Technology Innovation On Clamping System & Stretching

*Adopts servo motor to drive the two cranks to control the clamping system which can shorten the mold-clamping time and improve productivity, and also solve the swelling mold and big joint line problem with the effect of pressurize plate.

* Servo motor using for stretching to ensure the bottle blowing speed faster and more stable bottle quality.

|

|

|

Factory Pictures

Zhongshan chumful machinery co ltd is the one branch of Zhongshan Vfine machinery co ltd, which is a professional manufacturer of PET bottle blowing machines, that integrates the R&D, production, and sales. Since the development and design of the first generation linear automatic stretch blow molding machine, Vfine's technical team has focused in the PET market for 20 years. We've successfully supplied machines to many world-famous brands. Not only the bottle blowing machine,Vfine(CHUMFUL) also provide the turnkey plant service for all customers, we can offer from A to Z solution for all kind of PET bottle production, PET bottle water, and pet bottle beverage.

Company Advantages

1. Rich experience in designing and manufacturing the blowing machine,with over 20 years experience.

2. Customizable.

3. Each machine type has 3D drawing. And the machine parts are made according to international standards.

4. The machine quality is good,stable and durable with reasonable price.

5. Good after-sales service.

6. Good evaluation.

Pre-Sales Service

* Welcome to view our Factory.

* 24 hours on line answer your question.

* Help client choose the suitable machine.

* Take video as client's request.

After-Sales Service

* Training how to instal the machine, training how to use*Engineers available to service machinery overseas.

*We provide useful documents with machine.

* All spare parts are always available.

Packaging&Shipping

Molding machine to abroad will be packaged in wooden case. ln addition, we will also pack the machine according to the requirements of specific customers. Subject to the measurement of main blower, we will choose corresponding wooden case. Vfine Machinery is a professional mould machinery company and we will try our best to satisfy the kinds of demand of customers.

|  |  |

|  |  |