Full Servo Pet Bottle Manufacturing Machine

Product features

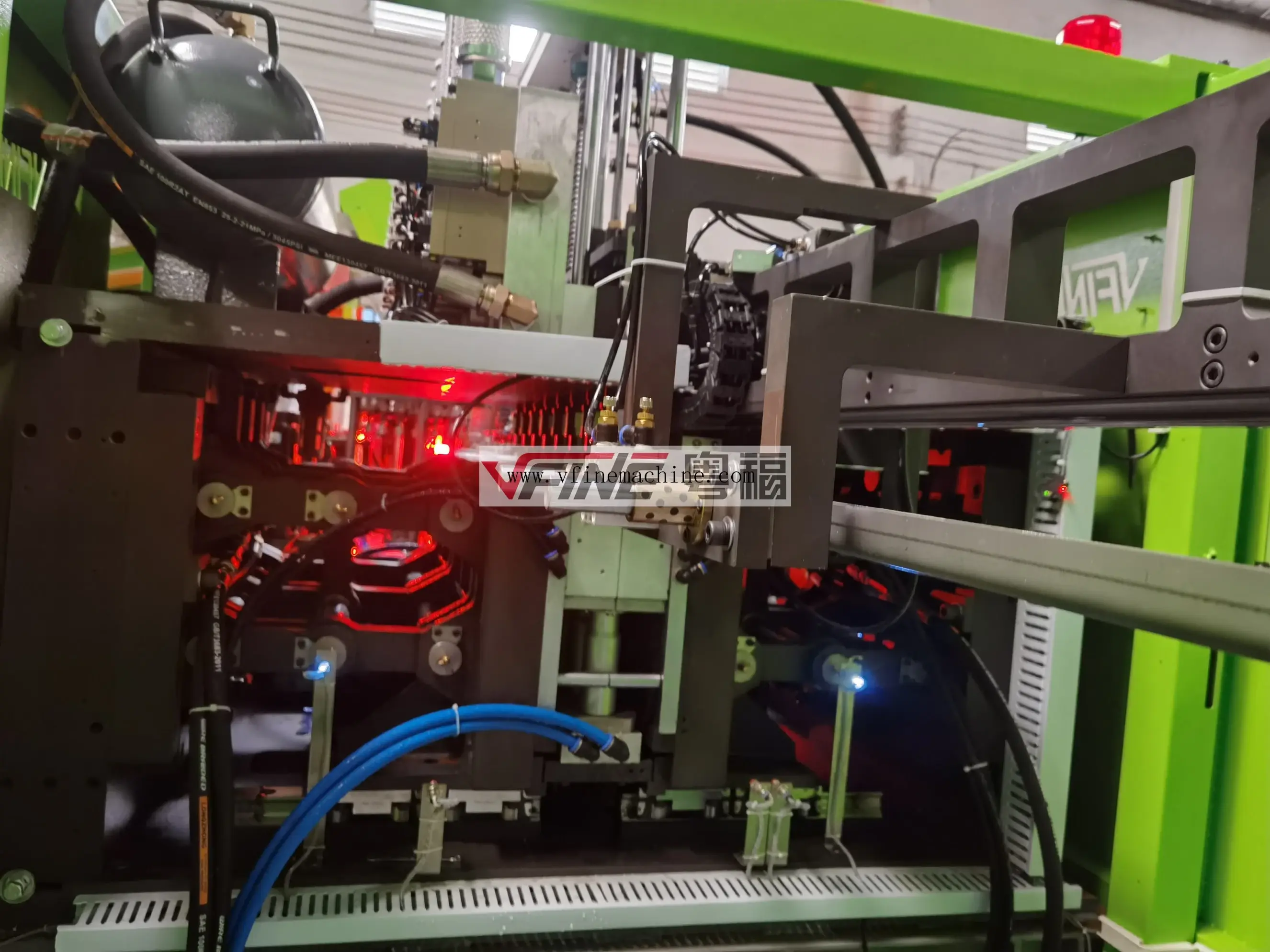

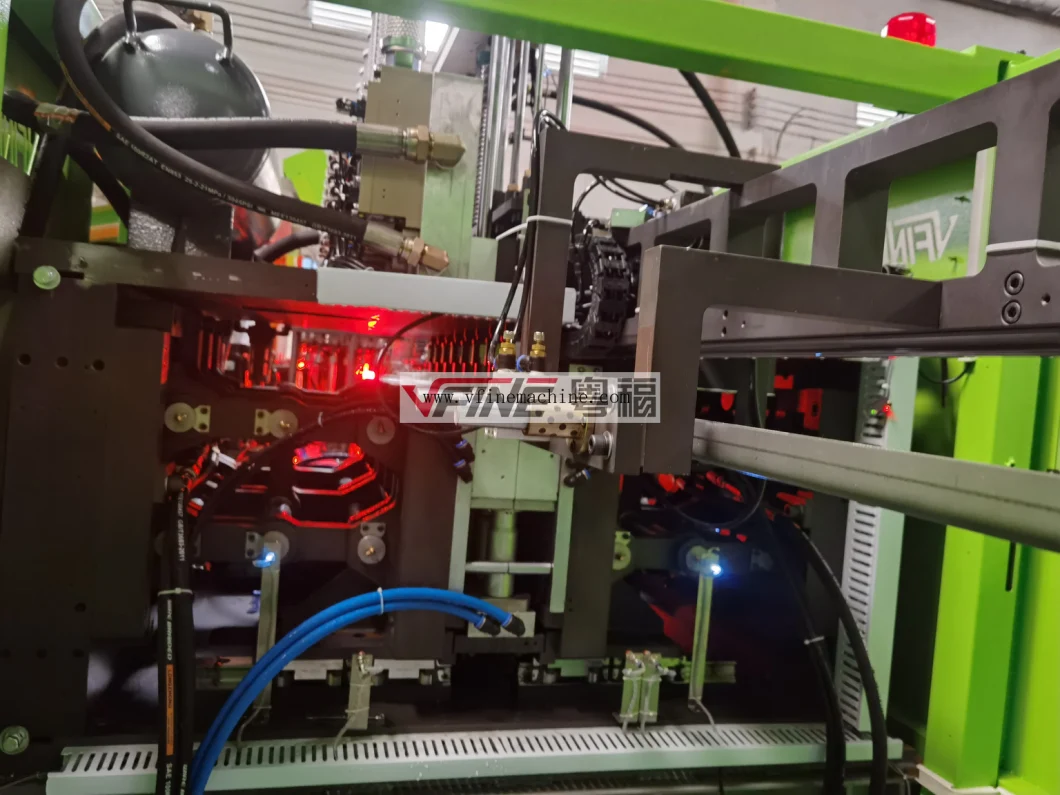

The Full Servo Pet Bottle Manufacturing Machine by Zhongshan Vfine Machinery Co., Ltd is a cutting-edge solution for producing PET bottles with precision and efficiency. With a fully servo-controlled structure, the machine ensures stability and accuracy throughout the entire manufacturing process. Its high-pressure air compensation mold locking mechanism guarantees top-quality bottle blowing, making it a reliable and energy-saving choice for businesses in need of high-speed production capabilities.

Company profile

As a leading provider of industrial machinery solutions, our company specializes in the design and production of high-quality full servo pet bottle manufacturing machines. With a strong focus on innovation and efficiency, our machines are equipped with cutting-edge servo technology to ensure precision and reliability in the production process. Our commitment to customer satisfaction drives us to deliver top-notch service and support, making us a trusted partner for businesses seeking to streamline their manufacturing operations. Whether you are a small start-up or a large corporation, our company is dedicated to helping you achieve your production goals with our advanced pet bottle manufacturing machines.

Why choose us

Established in 2010, our company is a leading manufacturer of Full Servo Pet Bottle Manufacturing Machines. We specialize in producing high-quality, efficient machines that are reliable and easy to operate. With a focus on innovation and customer satisfaction, we strive to provide the best solutions for our clients in the packaging industry. Our machines are designed to maximize productivity and minimize labor costs, making them a cost-effective choice for businesses of all sizes. Trust in our expertise and experience to help you streamline your production process and achieve your manufacturing goals with our state-of-the-art equipment.

Zhongshan Vfine Machinery Co., Ltd maintains stringent norms of quality to manufacture Full Fully Servo Automatic Pet Plastic Water Bottle Tank Stretch Blow Blowing Molding Making Moulding Manufacturing Farming Machine Plant Systems Price. The research and development team is the core competence to Full Fully Servo Automatic Pet Plastic Water Bottle Tank Stretch Blow Blowing Molding Making Moulding Manufacturing Farming Machine Plant Systems Price. It enables us to become a leader in the BLOW MOLDING MACHINE. Since the beginning,Zhongshan Vfine Machinery Co., Ltd have been sticking to the business principle of 'integrity' and bearing the mind of 'offering customers the best of us'. We are fully confident that we will make a great success in the future.

| Model NO. | YF-L10E | Making Method of Parison | Stretch Blow |

| Automation | Automatic | Computerized | Computerized |

| Certification | CE, ISO9001:2008 | After-sales Service | Includes |

| Product | Blow Molding Machine | Machine Capacity | 18000bph |

| Machine Type | Full Servo | Manufacture | Zhongshan Vfine Machinery Co Ltd |

| Transport Package | Wooden | Specification | 7m*2m*2.5m(l*w*h) |

| Trademark | vfine | Origin | China |

| HS Code | 8477109000 | Production Capacity | 50-100/Year |

| Package size per unit product | 670.00cm * 220.00cm * 250.00cm | Gross weight per unit product | 9000.000kg |

Product Description

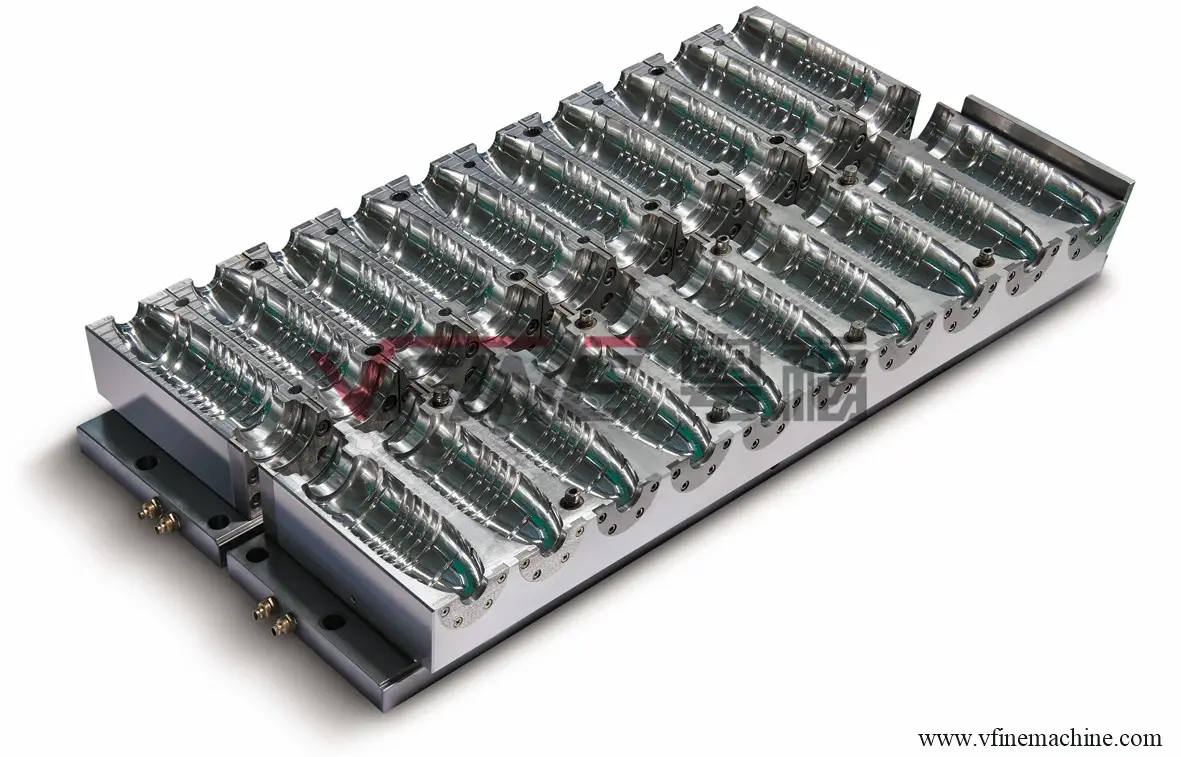

10-cavity, linear stretch blowing molding machine

Output: 18000bph

Max. Volume: 0.6L

(2)application scope

Suitable for producing PET water bottle, carbonate bottle, middle temperature filling bottle etc..

2. warm fill PET bottle for juice / ice tea / energy drink / CSD bottle:100ml - 2L

3. milk bottle from 100ml - 2L

4. medicine bottle from 100ml - 2L

all kinds of PET bottle in two stage processing

2) Servo control structure is adopted for preform feeding, transferring, stretching and mold opening / closing, which is efficient and stable;

3) The drawer type die fixing structure makes the mold change simple and fast, and it only takes 30 minutes to change the die quickly;

4) The high-pressure air compensation mold locking mechanism ensures the quality of bottle blowing. The joints of the machine forming group adopt self-lubricating bearings imported from Japan, and the whole forming group is equipped with a centralized self-lubricating system.

(4) Vfine blowing machine YF-L10E specifications

| MODEL | YF-L10E |

| Max Bottle Volumn | 600ml |

| Cavity number | 10 |

| output | 18000BPH |

| Machine size | 6700*2000*2500 |

| Machine weight | 9000kg |

PS: Specifications are subjected to change without future notice

short view over vfine blowing machine

High speed, fully eletrical, all servo control, intensively heating blowing machine

| YF-L1GLE | YF-L2GLE | YF-L2BLE | YF-L3BLE | YF-L4BLE | YF-L4LE | YF-L6LE | YF-L8LE | YF-L10LE |

| 3L - 30L | 3L-20L | 2L-5L | 2L-5L | 2L-5L | 100ml - 2L | 100ml - 2L | 100ml - 2L | 100ml - 2L |

| 500-600bph | 1200-2000bph | 2000bph | 3000bph | 4000-4500bph | 8000bph | 10000-11000bph | 14000-15000bph | 18000-20000bph |

traditional type servo control blowing machine

| YF-4LE | YF-6E | YF-6LE | YF-9E | YF-2LME | YF-3ME | YF-2BLE |

| 50ml-2L | 10ml -750ml | 50ml-2L | 10ml-750ml | 50ml-2L | 8ml-750ml | 1.25-8L (bottle with side handle, and without handle) |

| 2000-3200bph(thick bottle) 5500-6000bph | 4000-6000bph(thick bottle) 8500-9000bph | 5000-6000bph(thick bottle) 8500-9000bph | 7000-8000bph(thick bottle) 12000-13000bph | 1200-1800bph(thick bottle) 3000BPH(water bottle) | 1800-2700bph(cosmetic bottle) 4000-4500bph(water bottle) | 1000-1200bph(side handle bottle) 1300-1500bph(5L) |

80-92 degree filling temperature, hot fill bottle machine, these machines are available for produce common bottle with normal filling temperature

| YF-2LHE | YF-4LHE | YF-6LHE | YF-L6LHE | YF-L8LHE |

| 100ml-1.5L | 100ml-1.5L | 100ml-1.5L | 100ml-1.5L | 100ml-1.5L |

| 1000BPH | 2000BPH | 3000BPH | 3000-4000BPH | 4000-5000BPH |

wide neck, jar, food container bottle blowing machine

| YF-2LWE | YF-2LWE(152) | YF-4LWE | YF-4LWE(152) | YF-6LWE | YF-2BWE |

| Neck: 40mm-100mm | Neck: 40mm-140mm | Neck: 40mm-90mm | Neck: 40mm-140mm | Neck: 40mm-80mm | Neck: 80mm-130mm |

| 1200-1800bph | 1200-1800bph | 2400-3600bph | 2400-3600bph | 3600-4000bph | 1200-1500bph |

We have a professional after-sale service team, before the machine arrive, we will give consulting service about the machine's place, electricity, and water preparation works. after the machine arrives in the customer's factory, we also send the engineer for installation and make training for the customer's engineer, customer should take charge of the engineer's travel cost, board and lodging , and labor cost.

All the machines ship from vfine machinery, are well tested and with no less than 72hours continous running, and at least 1hour continous production test, which make sure that, all the equipments can be quickly make production in customer's factory.

we guarantee that, all the machine can finish installation and start production with 2days since our engineer commission, under the condition that the customer workshop meets the installation conditions.

During commission time, our engineer will make training for customer technician and workers, make sure that, the machine will be correct operated.

Zhongshan chumful machinery co ltd is the one branch of Zhongshan Vfine machinery co ltd, which is a professional manufacturer of PET bottle blowing machines, that integrates the R&D, production, and sales. Since the development and design of the first generation linear automatic stretch blow molding machine, Vfine's technical team has focused in the PET market for 20 years. We've successfully supplied machines to many world-famous brands. Not only the bottle blowing machine,Vfine(CHUMFUL) also provide the turnkey plant service for all customers, we can offer from A to Z solution for all kind of PET bottle production, PET bottle water, and pet bottle beverage.

VFINE Machinery has been keeping good cooperative relationship with customers since our establishing.

The satisfaction of our customers is the pursuit of every member of Vfine Machinery, the only way we service in the competitive market is to help our customers to full fill their requirement.

Vfine sales consultant

1. We can provide comprehensive and professional Suggestions on equipment selection.

2. Energy consumption calculation and investment income analysis can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product optimization Suggestions.

4. The stretch plastic bottle blow molding machine has remote maintenance function

Advantages of Vfine tech teams

1. More than 800 sets of customized machines in the market enable us to have rich experience across multiple industries.

2. Customize equipment models according to customer product characteristics.

3. Project responsibility system, closed-loop team cooperation between the design team and the process team, adjustment of the team, and joint creation of equipment that users are satisfied with.

4. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry.

5. Undertake a number of large projects, and has a group of senior technical personnel composed of the construction team, can build cable bridge, installation of a complete set of equipment.

Advantages of Vfine Machinery after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment.

5. Free training for customer technician while making installation

6. Special processing equipment to produce after-sales accessories to ensure rapid response to user needs.

Q1: Are you a trading company or a manufacturer?

Vfine(CHUMFUL) is a professional manufacturer for PET bottmachinesine, we also provide turnkey plant consultiservicesice for PET bottle production line, pet bottled water, and beverages production line for customers.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

All of Vfine machines are guaranteed at least one year, and we provide whole lifetime service for all customers, within the quality guarantee time, free offer wearing parts, and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to the seller's demand, and debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still cannot solve, we will arrange technician to your factory to solve the problems. The cost of technician arrangement you could see the cost treatment method of technician.

After guarantee time, we offer technical support and after-sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, and debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still cannot solve, we will arrange technician to your factory to solve the problems

Q3:When can I get my machine after I paid?

A3:We will deliver the machines on time according to the date we agreed on both sides.

Q4:How can I install my machine when it arrives?

before machine shipments, we have all marks for the future machine installation, take vdos for reference. For almost all of our old customers, can manage to install the machine under the vdo guide and on-line service.

For all new customers and those who cannot handle the installation, we send engineers to the customer's factory to make the installation. Meanwhile, we will make training for customer technician and machine operators.

Q5:What's the delivery time?

45-90 days after receipt of the deposit.

Q6: Where is your factory located?

Vfine locates in Zhongshan city, which is 1 hour away from Guangzhou airport and 2 hours away from Shenzhen airport.

Q7: How is your machine quality?

Our R&D engineer started to design and develop the PET blowing machine since 2001 for the first generation automatic linear PET bottle blowing machine, who have plenty of experience in the PET Bottle market, we keep improving the machine detail design and machine quality, till now we have successful cooperation with many world-famous brand, which also make us keep moving on for machine performance and let us take very serious control for our machine quality.

Q8: Can you make the bottle design?

Vfine(CHUMFUL) technical team not only make design of our machine, we also provide bottle design and bottle function testing for all customers.

Q9: What is the language of the PLC and touch panel?

we provide English, Spanish, Russian and Chinese version in the screen.

A: yes, the machine is available for water bottle, edible oil bottle, csd bottle, wine bottle, etc

Q11: is the blowing machine available for different bottle mold

A: yes, the machine is designed with very easy bottle mold change unit, only need 30minutes to change a mold

Q12: Do you provide customized service

Yes, VFINE(chumful) technical team gets plenty of experience in the pet BOTTLE market, we have lots of customized designs according to customer requirements, the special bottleneck, the special label, and the special bottle shape, and the bottle function.

Zhongshan Chumful Machinery Co Ltd

Zhongshan Vfine Machinery Co Ltd