VFINE - Pet Bottle Blowing Machine for Mineral Water Container Tank 4 6 Cavity Stretch Blow Molding Moulding Making Mold

By accurately grasping the pain points of customers, the Pet Bottle Blowing Machine for Mineral Water Container Tank 4 6 Cavity Stretch Blow Molding Moulding Making Molder Blower Auto Plastic Automatic Maker Factory developed by us has been supported and praised by the majority of customers in the market.The fields of application include Bottle Blowing Machine.

Concerning the industry development,Zhongshan Vfine Machinery Co., Ltd has been driven to develop new products to keep us competitive. High-end technologies are adopted to manufacture the product.When the product is manufactured and used in the field(s) of Bottle Blowing Machine, its stability and advantages can be fully played out. Research and development are the pillars on which the future of our company rests. Zhongshan Vfine Machinery Co., Ltd will put more emphasis on improving our R&D strength in the future for developing more creative and competitive new products.

| Model NO. | YF-6LE | Raw Material | Pet |

| Making Method of Parison | Stretch Blow | Automation | Automatic |

| Computerized | Computerized | Certification | CE |

| Transport Package | Wooden Pallet | Specification | 8500kg |

| Trademark | vfine | Origin | China |

| HS Code | 8407909090 | Production Capacity | 8sets/Month |

| Package size per unit product | 420.00cm * 200.00cm * 250.00cm | Gross weight per unit product | 6500.000kg |

Product Description

10000~20000BPH mineral water bottle blowing machine

Features:

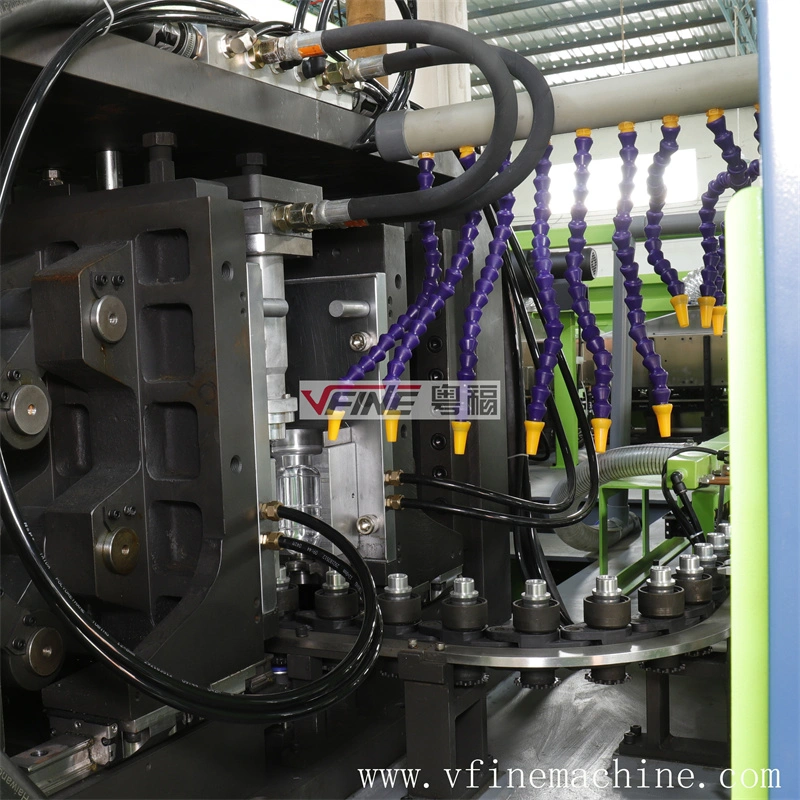

The machine is with full servo driver, high capacity and low energy consumption

The machine is suitable for water bottle, CSD bottle, medicine bottle

The machine is oil free machine, very clean, stable, quiet, and high efficiency.

| Number of cavity | Machine capacity | Model | Maximum bottle size |

| 6 | 12000BPH | YF-L6LE | 2L |

| 8 | 16000BPH | YF-L8LE | 2L |

| 10 | 20000BPH | YF-L10LE | 2L |

6-cavity, linear stretch blowing molding machine

Output: 8500-9000bph

Max. Volume: 0.6L

(2)application scope

Suitable for producing PET water bottle, carbonate bottle, middle temperature filling bottle etc.

(3)advantage of full electrical Vfine blowing machine

Linear structure, modular design, easy maintenance;

Full servo system

Full electrical blowing machine, servo motor together with high pressure air compensation device, ensure stable running;

Easy change mould

Drawer mould-fix structure,only need 30minutes for change mould of different bottle shape with the same neck size;

Save energy

The machine includes high pressure air recycle system, which can save about 25% high pressure air, reduce energy lost;

High efficiency

The machine output of each cavity is 1400~1500bph.

The machine includes auto-lubricating system; ensure the machine running stable and efficiency.

Safety

The machine includes safety protecting device, ensure production security.

(4) Vfine blowing machine YF-6E specifications

| MODEL | YF-6E |

| Max Bottle Volumn | 600ml |

| Cavity number | 6 |

| output | 8500-9000BPH |

| Machine size | 4000*2000*2500mm |

| Machine weight | 6500kg |

| MODEL | YF-4LE |

| Max Bottle Volumn | 2000ml |

| Cavity number | 4 |

| output | 5500-6000BPH |

| Machine size | 4000*2000*2500mm |

| Machine weight | 6500kg |

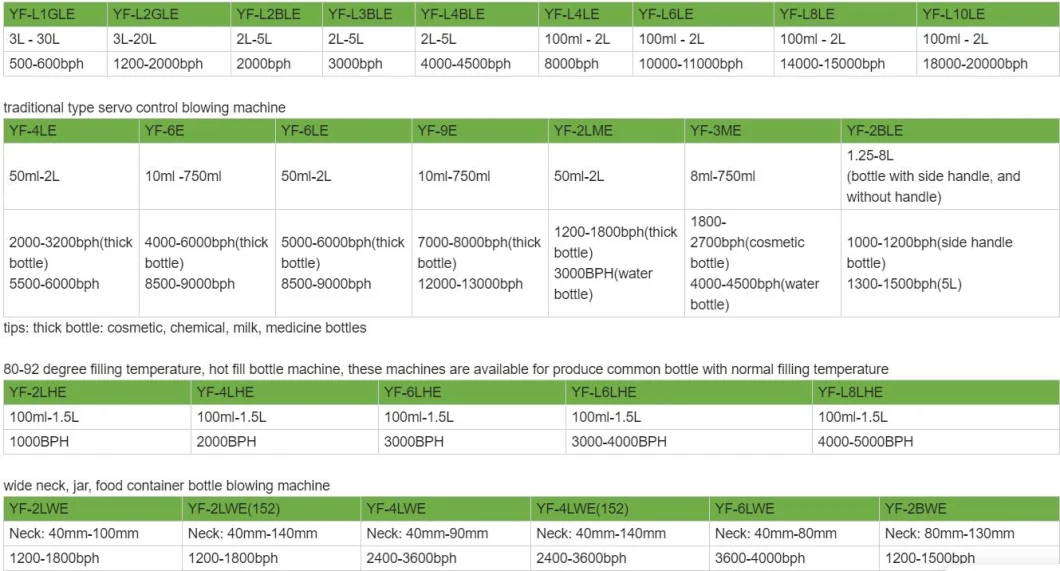

VFINE MACHINERY PRODUCT LIST SHORT VIEW

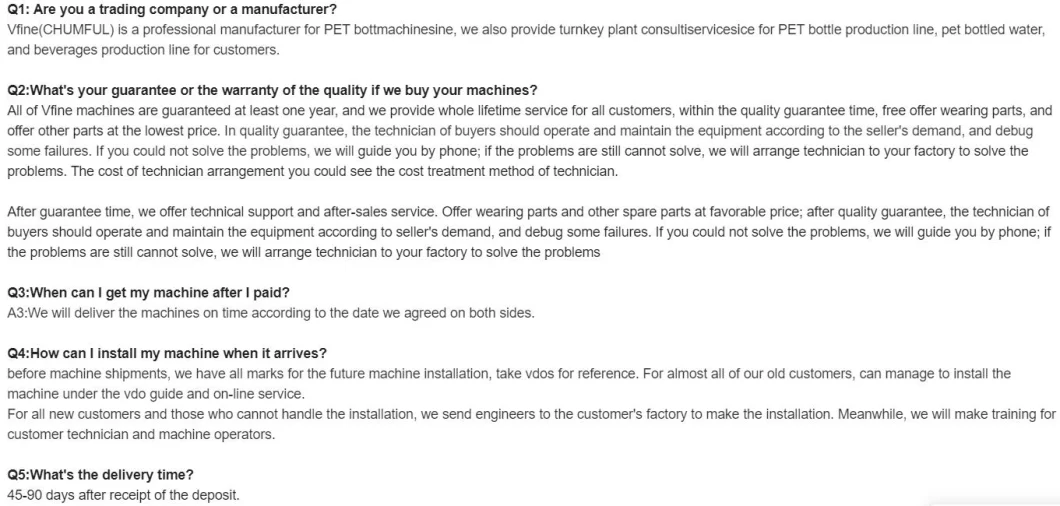

We have a professtional after-sale service team, before machine arrive, we will give consulting service about the machine place, eletricity, and water prepare works. after machine arrive in customer factory, we also send engineer for installation, and make training for customer's engineer, customer should take charge of the engineer travel cost, board and lodging and labor cost.

Not only blow machine, we also provide turnkey project service of pet bottle design, PET bottling equipment line, PET bottle filling, and packing.

A: yes, the machine is available for 3L-10L water bottle, edible oil bottle, etc

Q11: is the blowing machine full electrical

A: the machine is control by full servo for all units, no need prepare low pressure air for the blowing machine

Q12: is the blowing machine available for different bottle mold

A: yes, the machine is designed with very easy bottle mold change unit, only need 30minutes to change a mold

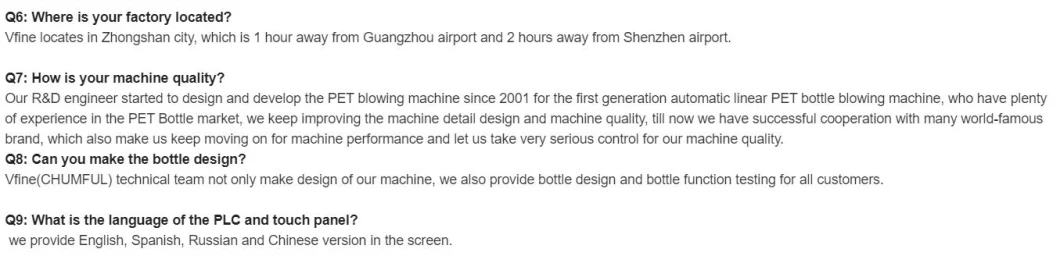

zhongshan vfine machinery co ltd

zhongshan Chumful machinery co ltd