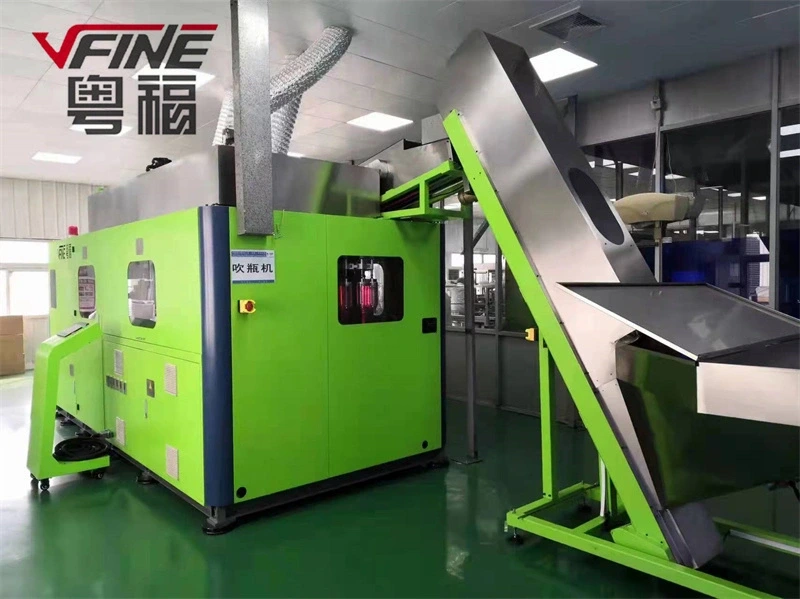

VFINE - Full Automatic Pet Plastic Water Bottle Tank Blowing Blow Molding Making Machine Blower Manufacturing Jar Stretch Mouldling Machinery Manufacturers Price China 5L 10L 15L 20L 5Gallon blow molding machine

Always putting an emphasis on the improvement of the research and development, Zhongshan Vfine Machinery Co., Ltd has finally developed Full Automatic Pet Plastic Water Bottle Tank Blowing Blow Molding Making Machine Blower Manufacturing Jar Stretch Mouldling Machinery Manufacturers Price China. The product with improved properties and features is expected to lead the trend of the industry. Full Automatic Pet Plastic Water Bottle Tank Blowing Blow Molding Making Machine Blower Manufacturing Jar Stretch Mouldling Machinery Manufacturers Price China provides not only excellent quality, but also very favorable price. With years of familiarity and expertise in this work area, Zhongshan Vfine Machinery Co., Ltd has evolved as an affluent manufacturer and supplier in the market, and there is a great possibility that the company will have a better development in the future.

| Model NO. | YF-L1GLE | Making Method of Parison | Stretch Blow |

| Automation | Automatic | Computerized | Computerized |

| Certification | CE, ISO9001:2008 | After-sales Service | Includes |

| Product | Blow Machine | Transport Package | Wooden Package |

| Specification | 4*2.2*2.5m(L*W*H) | Trademark | VFINE |

| Origin | China Guangzhou | HS Code | 8477300000 |

| Production Capacity | 100set/Year | Package size per unit product | 300.00cm * 200.00cm * 250.00cm |

| Gross weight per unit product | 4500.000kg |

Product Description

Flexibility for food and beverage producers, medicine packing industry, and daily product makers.

Vfine PET bottle blowing machine offers the maximum flexibility for the container. The PET bottle can be designed in various bottle shapes and sizes without compromising on production rates or light-weighting possibilities.

The transparent, light, resistant feature makes PET bottles to be the best choice for food and beverage makers as the product container. The producers need sustainable liquid-packaging solutions that deliver product quality, flexibility, reliability, lower cost, and brand impact. With vfine, you can benefit from decades of experience with PET and blow for a tailored solution that caters specifically to your needs.

Good quality as well as a stable performance machine, reasonable investment leads bottle makers, food and beverage producer to consider the linear type machine as the best choice. Vfine linear type stretch PET Bottle Blowing machine comes to be one of the best choices, with over 20years of technical background, the wonderful consult service, training, and after-sale service support make the product for the user without worry for long term.

Full automatic, full eletrical control for the bottle blowing, gives users a high efficient, energy-saving, safe and humanized production experience.

All operations includes blowing setting, lamp setting, speed setting, stretch setting, all can be done from the human screen.

Quick view

Plastic Processed: PET

Max.Bottle Height(mm): 330 mm

Neck Diameter(mm): 38 mm

Max.Bottle Diameter(mm): 105mm

Bottle Volume(ml):2000 ml

Production Capacity (BPH): 6000-1000BPH

Condition: New

Application: PET bottle

Blow Mounding Type: Stretch Blow Mounding

Place of Origin: Zhongshan, China

Brand Name: Vfine Machinery

Voltage: According to Customer Inquiry

Dimension(L*W*H): According to Customer Inquiry

Certification: CE

Hollow part volume: 3L-30L

High-Pressure Valve Brand: PARKER

Automation: Automatic

Warranty:2 years

Delivery time: 90days

Voltage: 220V/380v/415v/460v 3Phase 50HZ/60HZ

| machine model | YF-L1GLE |

| Machine weight | 4500kg |

| bottle volume | 3L-30L |

| machine size | 3m*2m*2.5m |

| Voltage | 220V/380v/415v/460v 3Phase 50HZ/60HZ |

| power | 52kw |

| production capacity | 600-1000BPH |

quick view of vfine blowing machine

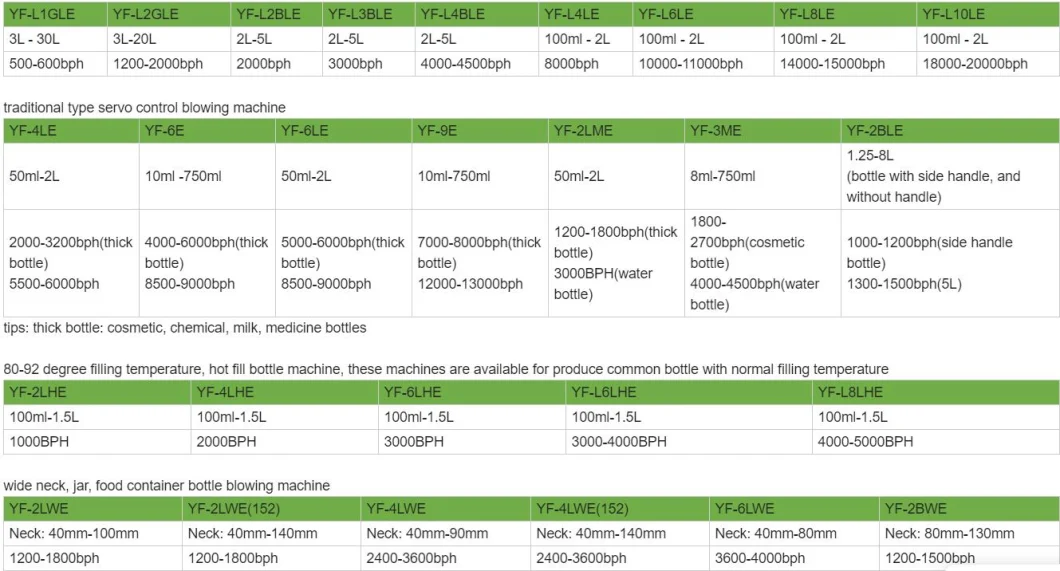

High speed, fully eletrical, all servo control, intensively heating blowing machine

traditional type servo control blowing machine

80-92 degree filling temperature, hot fill bottle machine, these machines are available for produce common bottle with normal filling temperature

wide neck, jar, food container bottle blowing machine

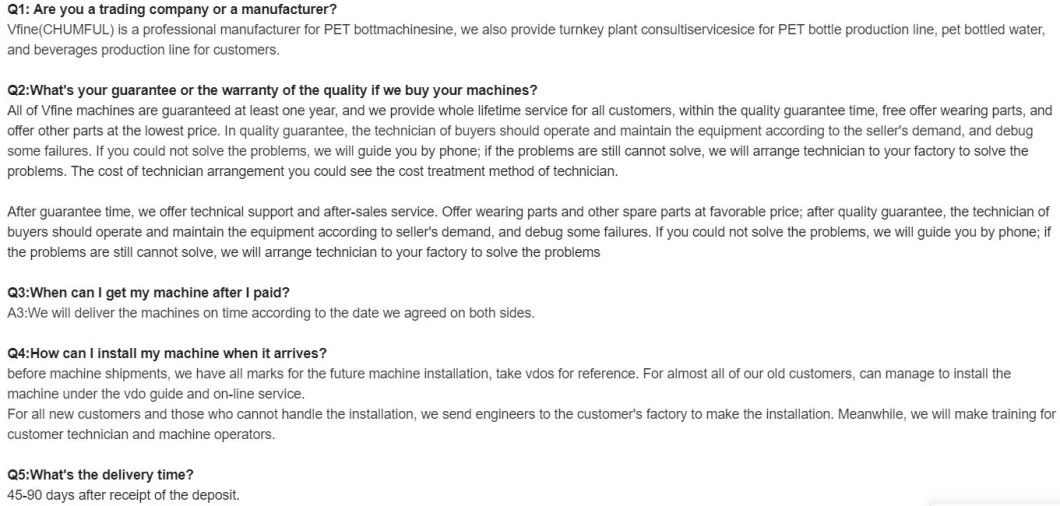

We have a professional after-sale service team, before the machine arrive, we will give consulting service about the machine's place, electricity, and water preparation works. after the machine arrives in the customer's factory, we also send the engineer for installation and make training for the customer's engineer, customer should take charge of the engineer's travel cost, board and lodging , and labor cost.

All the machines ship from vfine machinery, are well tested and with no less than 72hours continous running, and at least 1hour continous production test, which make sure that, all the equipments can be quickly make production in customer's factory.

we guarantee that, all the machine can finish installation and start production with 2days since our engineer commission, under the condition that the customer workshop meets the installation conditions.

During commission time, our engineer will make training for customer technician and workers, make sure that, the machine will be correct operated.

- Zhongshan chumful machinery co ltd is the one branch of Zhongshan Vfine machinery co ltd, which is a professional manufacturer of PET bottle blowing machines, that integrates the R&D, production, and sales. Since the development and design of the first generation linear automatic stretch blow molding machine, Vfine's technical team has focused in the PET market for 20 years. We've successfully supplied machines to many world-famous brands. Not only the bottle blowing machine,Vfine(CHUMFUL) also provide the turnkey plant service for all customers, we can offer from A to Z solution for all kind of PET bottle production, PET bottle water, and pet bottle beverage.

VFINE Machinery has been keeping good cooperative relationship with customers since our establishing.

The satisfaction of our customers is the pursuit of every member of Vfine Machinery, the only way we service in the competitive market is to help our customers to full fill their requirement.

Vfine sales consultant

1. We can provide comprehensive and professional Suggestions on equipment selection.

2. Energy consumption calculation and investment income analysis can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product optimization Suggestions.

4. The stretch plastic bottle blow molding machine has remote maintenance function

Advantages of Vfine tech teams

1. More than 800 sets of customized machines in the market enable us to have rich experience across multiple industries.

2. Customize equipment models according to customer product characteristics.

3. Project responsibility system, closed-loop team cooperation between the design team and the process team, adjustment of the team, and joint creation of equipment that users are satisfied with.

4. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry.

5. Undertake a number of large projects, and has a group of senior technical personnel composed of the construction team, can build cable bridge, installation of a complete set of equipment.

Advantages of Vfine Machinery after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment.

5. Free training for customer technician while making installation

6. Special processing equipment to produce after-sales accessories to ensure rapid response to user needs.

Zhongshan Chumful Machinery Co ltd

Zhongshan Vfine Machinery Co ltd