Features of main blowing machine:

Save energy, flexible:

Single channel preform in-feed, production capacity of the machine is no less than 1200BPH, and the efficiency is high; the equipment combines the advantages of the rotary machine and the linear machine, with a high energy utilization rate and simple and convenient operation.

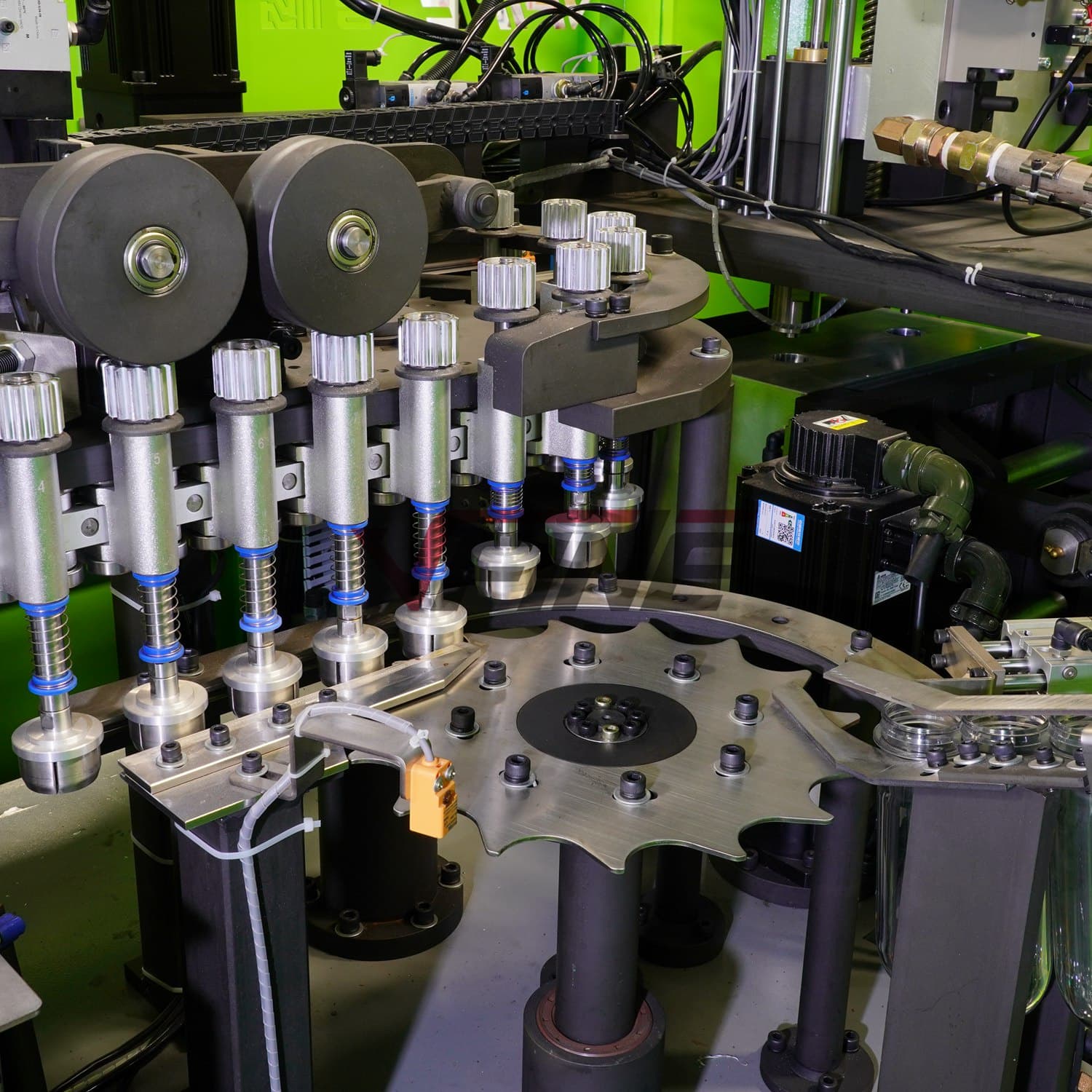

Fast mold change:

Drawer-type mold locking structure, easy and quick mold change, no more than 30 minutes to change the mold.

Intelligent control system, which can finish all parameter settings, equipment operation, and troubleshooting on the touch screen.

Stable equipment performance and low maintenance cost.

Oil-free preform transfer system, there is no risk of preform getting polluted.

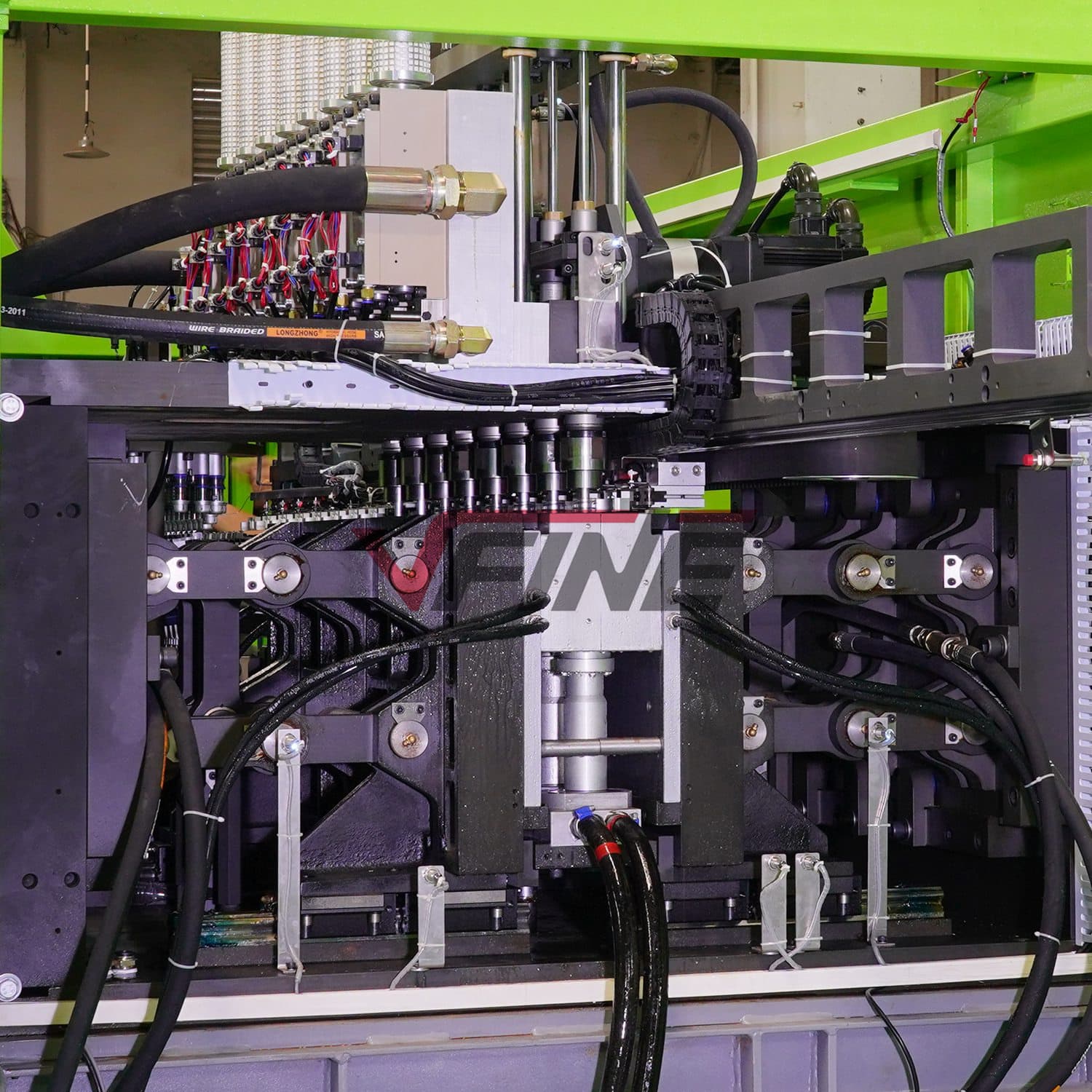

The equipment structure design is compact, occupying a small space.

Powerful temperature control system can ensure constant heating output and ensure the stability of preform heating.

The whole machine frame and clamping plates are annealed; and the plane and hole processing are finished at one time in the CNC to ensure that the machine frame and template are accurate, non-deformed, and durable.

Powerful cooling system to ensure that the thin-walled preform neck bottles and light-weight bottles are not deformed.

Advantages of VFINE Blowing Machine:

* Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

* High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

* High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

* Ideal cooling system make the finished bottles without any flaws.

References&Certifications:

![20L Big Size Bottle Blow Molding Machine 10]()

![20L Big Size Bottle Blow Molding Machine 11]()

Factory Pictures

Zhongshan chumful machinery co ltd is the one branch of Zhongshan Vfine machinery co ltd, which is a professional manufacturer of PET bottle blowing machines, that integrates the R&D, production, and sales. Since the development and design of the first generation linear automatic stretch blow molding machine, Vfine's technical team has focused in the PET market for 20 years. We 've successfully supplied machines to many world-famous brands. Not only the bottle blowing machine,Vfine(CHUMFUL) also provide the turnkey plant service for all customers, we can offer from A to Z solution for all kind of PET bottle production, PET bottle water, and pet bottle beverage.

![20L Big Size Bottle Blow Molding Machine 12]()

More Detailed Information

![20L Big Size Bottle Blow Molding Machine 13]()

Training: customers can send technician to vfine factory for 7-10 days training by buyers own charge

Delivery time: 90 days after confirmation of bottle designed and receipt of the down payment

Packing: Included the packing cost.

Guarantee: We promise that our goods are all new and not used. They're made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract. The machine is guaranteed in 12months from the date of commissioning signed or 13months from bill of loading with the normal operation conditions and seller shall be in charge of installation of machine.

After sales service:

After checking, within the quality guarantee time, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller's demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not be solved, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

After quality guarantee, we offer technology support and after sales service, offering wearing parts and other spare parts at a favorable price and arrange technical help if you have any problems.

Installation: Vfine would send engineer to Any installation outside of China, but buyer shall pay traveling expenses, including but not limited to, air ticket fees, 3 star-level boarding lodging fees, and all expenses for seller engineers' trips, also buyershould be apply the visa for seller's engineers. Buyer need also pay the salary for engineer.

Packaging&Shipping

Under normal conditions, the blow molding machine to abroad will be packaged in wooden case. ln addition, we will also pack the machine according to the requirements of specific customers. Subject to the measurement of main blower, we will choose corresponding wooden case, Vfine Machinery is a professional mould machinery company we will try our best to satisfy the kinds of demand of customers.