PET Blow Molding Machines Complete Guide

Ever wondered how your water bottles are made? Or how juice, soda, detergent, hand wash and even oil bottles get their shape so perfectly every time? PET blow molding is the answer and it all begins with the proper machine. This guide will cover all the basics of how does a PET blow molding machine works, whether you are a beginner or you want to change your existing equipment. Read on to learn more.

What Is a PET Blow Molding Machine?

A PET blowing machine is a machine that uses pre-made plastic tubes known as preforms. After heating, stretching and high-pressure air blowing, converts the preforms into bottles. Sounds simple? It actually is!

These machines are fast, accurate and efficient. They can produce hundred thousands of bottles a day. They do it with precision and consistency so that every bottle should appear and perform just perfectly.

Types of PET Blowing Machines: Which One’s Right for You?

There’s more than one way to blow a bottle. Let's break down your options:

1. Single-Stage PET BLOW MOLDING Machines

Single-stage machines do two jobs at once. They make the bottle shape and blow it into formed bottle all in one go. You don’t need a separate machine to make preforms. These machines are great if you don’t have much space or want to make many bottle shapes in small batches. They’re a little slower but perfect in the bottle outlook, it is popular for the cosmetic and medical package

2. Two-Stage PET BLOW MOLDING Machines

Two-stage machines, First stage, injection machine produce the preform. Second stage, blowing machine heat up the prefrom again and blow it into a bottle. These machines are ideal for large-scale projects. They work in high efficiency, it is popular for water, food container, toy container, edible oil, chemical, cosmetic, medical package etc. If your business needs high efficient and high output, this is a smart choice.

3. Fully Automatic vs. Semi-Automatic Machines

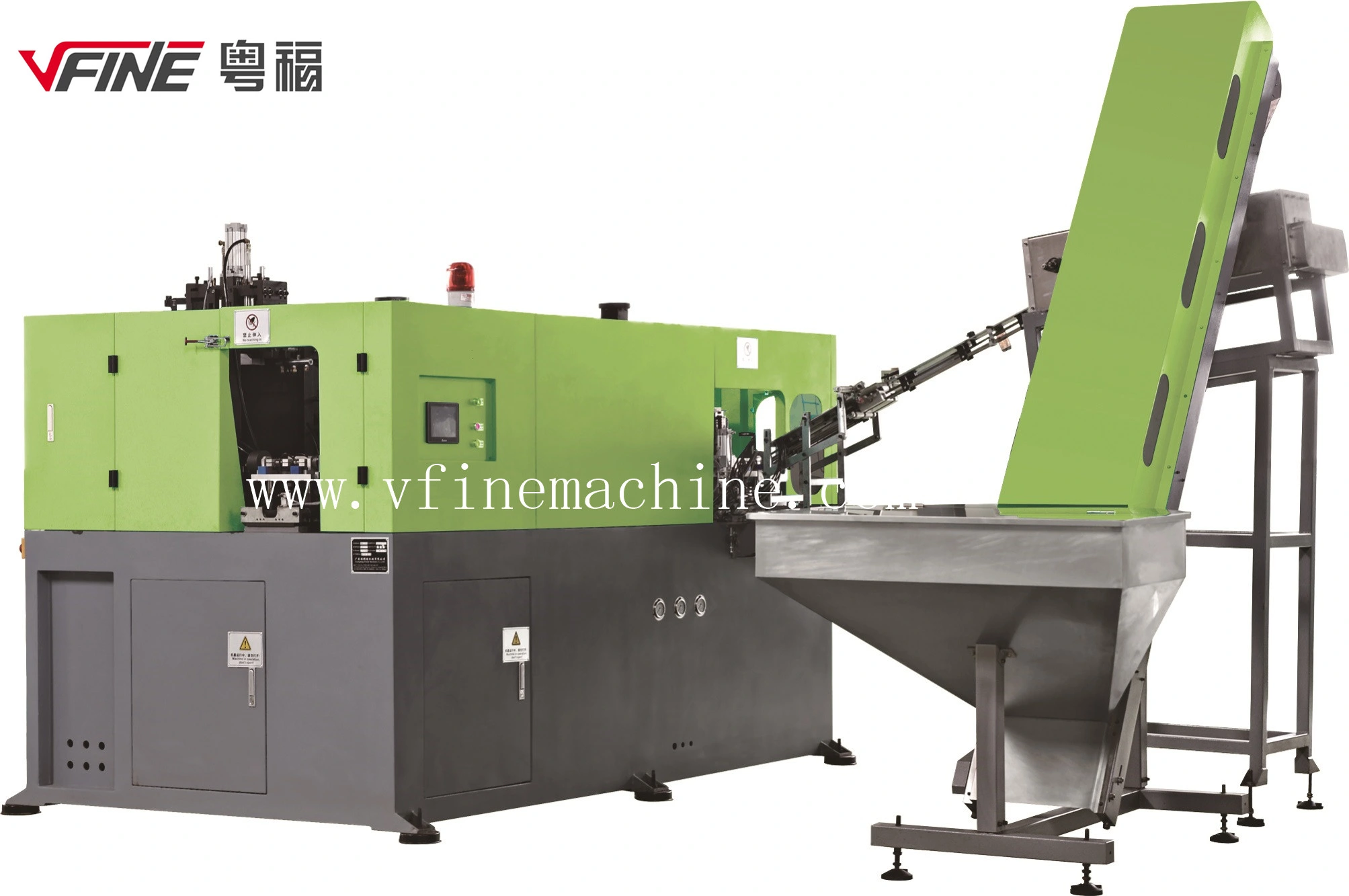

Fully automatic PET blow machines finish automatic preform infeed, preform heating, bottle blowing and the bottle take-out. You don’t need to touch a thing. They’re extremely fast and ideal for large businesses that want to reduce labor costs.

Semi-automatic PET bottle blowing machines, You have to manual finish the preforms load or move things, operate the bottle blowing, bottle take out . ThesePET blowing machines are cheaper and more suitable to small scale businesses.

Pro Tip: Choose a machine that fits your business size, bottle design requirements as well as your budget.

What Are the Advantages of PET Material?

PET material is a widely used plastic to make bottles.

◆Mechanical Strength & Durability

High Impact Resistance: PET exhibits 3–5 times greater impact strength than many plastic films (e.g., PVC or PP), making it ideal for beverage bottles and packaging subjected to physical stress.

Flexibility & Fatigue Resistance: Maintains structural integrity under repeated bending or compression, crucial for reusable containers and industrial components.

Dimensional Stability: Low shrinkage and resistance to deformation under load ensure precision in engineering parts like gears and automotive components

◆ Chemical & Environmental Resistance

Solvent Inertness: Resists oils, fats, weak acids/bases, and alcohols, ensuring safe storage of chemicals, foods, and cosmetics.

Hydrolysis Risk: Susceptible to degradation in hot water (>60°C) or strong alkaline solutions, requiring additives for specific applications.

◆Thermal Stability

Broad Temperature Range: Withstands -70°C to 120°C long-term, with short-term tolerance up to 150°C. Suited for frozen food packaging, automotive parts, and electronics.

Enhanced Variants: Glass fiber-reinforced PET tolerates 250°C (e.g., solder-compatible electrical connectors).

◆Barrier Properties

Low Permeability: Blocks O₂, CO₂, and water vapor, extending shelf life of carbonated drinks, oils, and pharmaceuticals.

UV Protection: Inherent UV resistance preserves light-sensitive contents (e.g., medicines, perishable goods).

◆Optical & Surface Properties

Clarity & Gloss: >90% transparency rivals glass, enhancing product visibility in retail packaging.

Smooth Surface: Prevents adhesion of contaminants and enables high-quality printing/metallization.

◆Safety & Sustainability

Food/Medical Compliance: FDA/EC-approved for direct food contact, medical devices (e.g., sutures, packaging) due to non-toxicity.

Recyclability: Mechanically recycled into fibers (clothing, carpets) or new bottles.

Limitation: Global recycling rates remain low (<30%); dependent on infrastructure improvements.

Emerging plant-based PET reduces fossil fuel reliance.

◆Cost-Effectiveness & Processability

Low Raw Material Cost: Ethylene glycol (PET feedstock) is cheaper than alternatives (e.g., PBT’s butanediol).

Versatile Processing: Adaptable to injection molding, blow molding, and thermoforming, though requires rigorous drying to prevent hydrolysis.

PET bottles offer an ideal combination of strength, safety, clarity, chemical resistance, and recyclability cements; hence their preference by numerous industries.

What Is the Application Scope for PET Bottles?

So, where do we see PET bottles in action? Pretty much everywhere!

● Beverage industry: Water, soda, juice and sports drinks.

● Food products: Sauces, cooking oil and vinegar.

● Personal care: Shampoo, conditioner or lotions.

● Household goods: Cleaners and detergents.

● Medical and pharma: Syrup bottles or vitamin containers.

● Alcohol: beer, wine, destification alcohol

PET bottles are strong and they are all-rounders, that's why they are used widely.

The Workflow of the Automatic PET Blow Molding Machine

Here’s where the magic happens step by step:

▶1. Preform Infeeding: The preform will automatic load into the machine

▶2. Preform Heating: Preforms are warm up by the infrared lamps, heat until they’re soft and stretchable.

▶3. Mold Closing: The heated preform is transferred into a bottle mold, and the mold closes tightly around it.

▶4. Stretching: A stretch rod comes into the mold cavity and stretches the soft preform vertically to match the shape of the mold.

▶5. Blowing: The preform is blown with high-pressure air, which help the preform shaping to the design mold.

▶6. Air Exhausting: The air is released, and the now-formed bottle cools quickly.

▶7. Bottle Discharging: The finished bottle is automatically take out, ready for use or filling.

That’s it, the bottle is born in just a few seconds!

Important Factors for Choosing a PET Blow Molding Machine

Before you make a final decision, ask yourself:

✔1. What production output do you need?

The daily general production and the working hours

✔2. What bottle sizes will you produce?

Make a research on the market, to check the popular bottle sizes

✔3. Do you need our support for the product design? Or do you already have your product design?

Vfine can offer product design, and can make mold according to customer existing product.

✔4. What is the content of the bottle?

Water, Drinks, Milk, Cook oil, medical product, or cosmetics, food, etc?

✔5. Do you need custom molds or a full turnkey setup?

VFINE can provide both.

✔6. What about long-term support and cost efficiency?

Get a machine that is easy to maintain and there should be good service behind it.

It may take some time to ask and answer these questions now, but it will save you a ton of time (and a ton of money) in the future.

Advantages of VFINE Machinery PET Blow Molding Machines

VFINE Machinery’s PET bottle blowing machines are built to impress. Here’s what sets our machines apart:

● Full-servo technology for top-notch speed and control

● High-standard design with versatile compatibility for various container types, ensuring consistent bottle quality and production efficiency.

● The high-performance heating system guarantees stringent temperature management for premium bottle manufacturing, achieving minimal production waste.

● All load-bearing elements - from the reinforced frame to mold platens and custom components - undergo precision CNC machining small tolerances. This rigorous approach delivers 20+ year fatigue resistance and ensure the machine durable, and strong

● Oil-free prefrom tranfering ensure the production with very low polution risk.

● Energy-saving systems that help you cut power costs.

● Smart and friend touch interfaces that are simple to use, even for beginners.

● Designed for high output with low maintenance cost.

You get fast results without sacrificing quality or your wallet!

VFINE Machinery’s Blow Molding Solutions and Reference

With over 20 years of experience, VFINE Machinery has helped customers in more than 50 countries succeed in the bottle-making business.

◆We offer:

● Custom solutions for PET, HDPE, and PP bottles production line

● Bottle-making, filling and packaging support under one roof.

● Knowledgeable and skillful engineers to assist with installation, training and troubleshooting.

Want real-world proof? VFINE machines are already working in food and beverage factories, personal care brands, and household product lines across the globe.

Conclusion

So, how does a PET blow molding machine work? It is a combination of smart engineering, compressed air, and right timing. However, when deciding on the suitable machine to fit your business, there is more to consider than the specification.

Know your product. Understand the process. Choose a PET blowing machine that fits your goals. And when in doubt, go with a brand that stands behind its work, like VFINE Machinery. Our machines are built to last, built to perform, and built to help your business grow.