3cavity 2.5L to 5L Big Size Container Blow Molding Equipment Servo Control Fully Automatic Plastic Pet Water Beer Detergent Condiment Oil Tank Bottles Blowing Machinery at 3600BPH High Speed High Quality

Professional Big Size Bottle Blow Molding Machine manufacturers

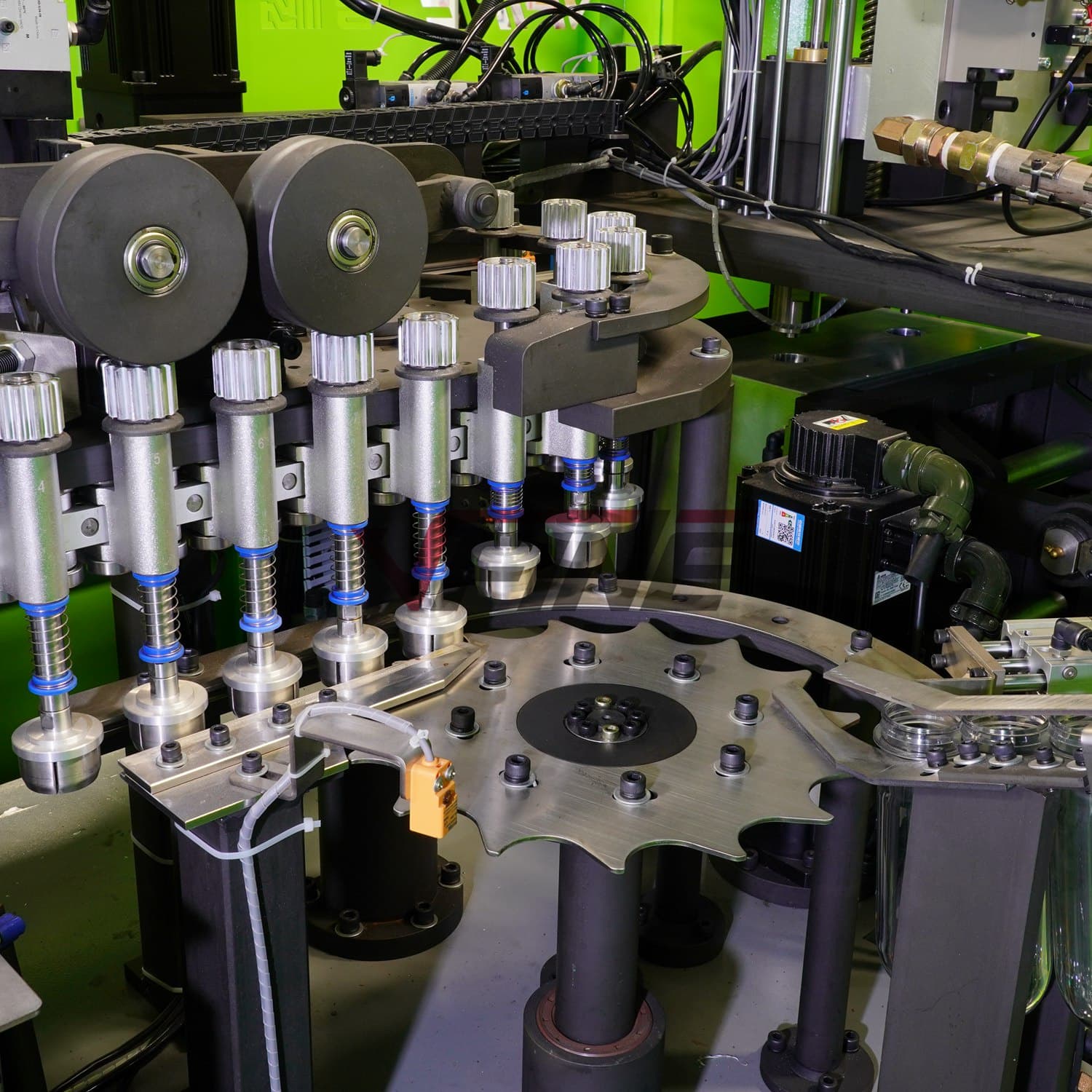

3-cavity, linear stretch blowing molding machine

Output: 3000-3600bph

Max. Volume: 5L

(2)application scope

Suitable for producing 2.5L-5L PET water bottle, carbonate bottle, middle temperature filling bottle etc.

|

|

|

|

|

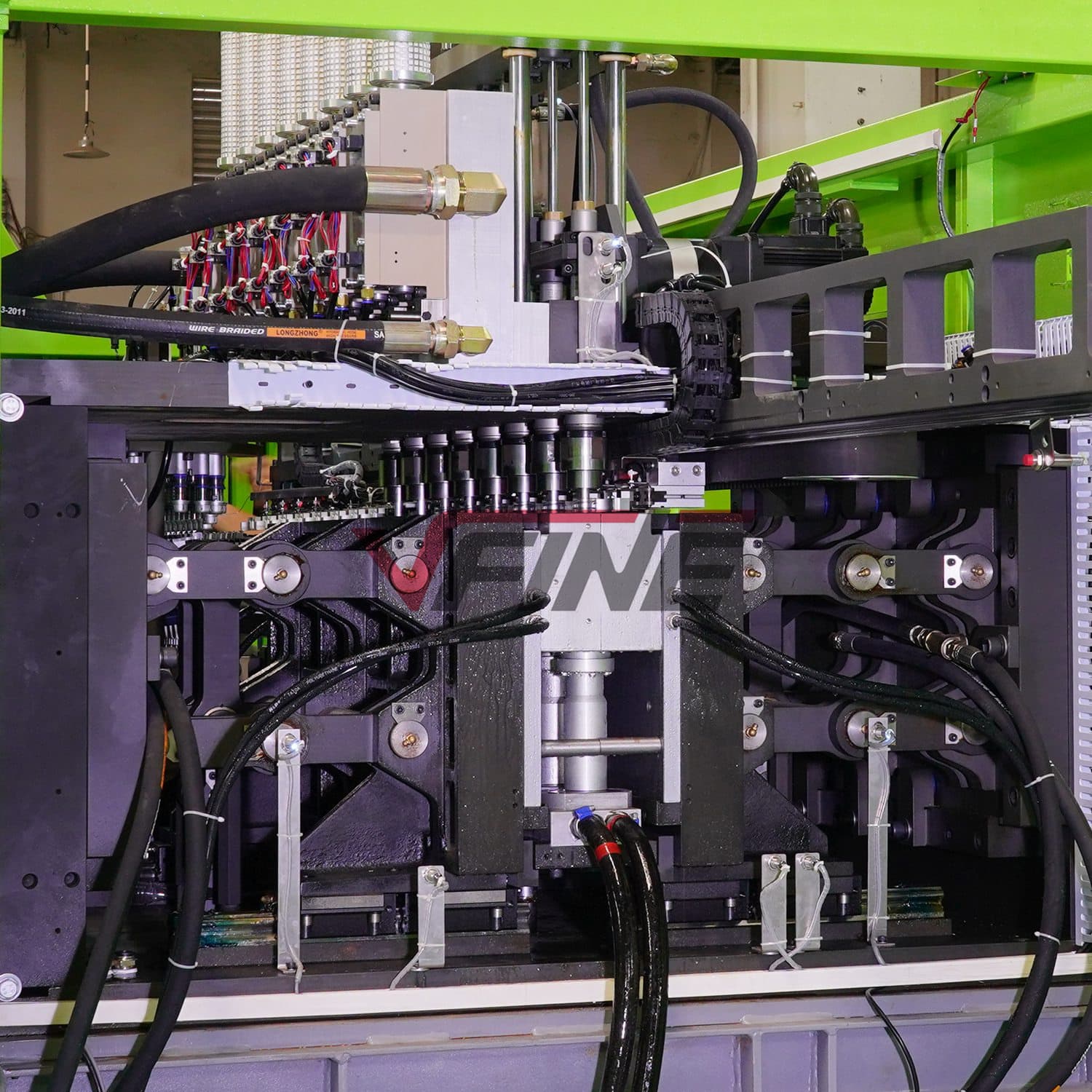

Features of main blowing machine:

1.Fast and fully automatic conveying of preforms reduces costs and increases profits for enterprises.

2.The man-machine interface control program imported from Germany's Simens or Japan's Mitsubishi has the advantages of stable performance and simple operation

3.The photoelectric switches , proximity switches , and relays select the Japan's Omron , the control accuracy is accurate and the reaction speed is fast.

4.Imported infrared lamp heating , strong penetrating power , uniform heating , high efficiency and energy saving 40% .

5.French Schneide air switches , contactors , switchpower , etc , durable .

6.Mitsubishi servo motor drive , equipped with Taiwan's Feston reducer , stable , efficient , energy-saving

7.German FEiSTO oil and water separator and Japanese SMC action valve , switching speed , low failure rate , safe and reliable operation

8.American Parker high-pressure blow valve, high sensitivity,rapid bowing product molding

9.Action and blowing are divided into two parts to meet the needs of blowing bottles , different movements of different air pressure , to achieve high pressure blowing products .

10.Servo motor unique two-way synchronous lock mold , opening and closing mold speed , smooth movement

11.High-power Mitsubishi servo motor fast synchronous stretching , effective control of product blow-making type , high yield.

12.The whole machine has automatic alarm , automatic fault detection and judgment function easy and fast maintenance

|

|

|

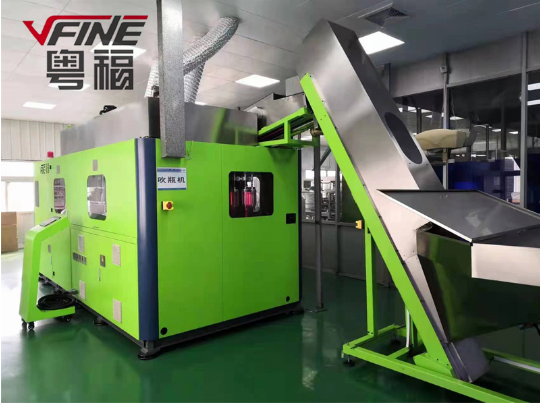

Factory Pictures

Zhongshan chumful machinery co ltd is the one branch of Zhongshan Vfine machinery co ltd, which is a professional manufacturer of PET bottle blowing machines, that integrates the R&D, production, and sales. Since the development and design of the first generation linear automatic stretch blow molding machine, Vfine's technical team has focused in the PET market for 20 years. We've successfully supplied machines to many world-famous brands. Not only the bottle blowing machine,Vfine(CHUMFUL) also provide the turnkey plant service for all customers, we can offer from A to Z solution for all kind of PET bottle production, PET bottle water, and pet bottle beverage.

Company Advantages

Customer service

1, After the equipment acceptance, we guarantee the quality with one year, and serve in time when need. Once equipment goes wrong, after receiving information, under the condition that there is no special things, maintenance man will respond with 48 hours.

2, Beyond the period of warranty, this company will offer technological service and customer service for life.

Technical service

1, Installation and adjustment

After the equipments are arrived at the customer's site, the customers is responsible for unpacking and arranging the equipment according to the placement drawing; and do under our install-adjust technicians' guidance.

According to requirement of water, electricity, hydraulic oil, air and the demands of quality level and pipeline, the User should connect the wire, cable and pipe of water, air and steam to the special position ordered in the installation area of production line ahead of time. Other relevant matching equipment and project should be finished before we adjust our equipment.

We'll bring a suit of portable installation and adjustment tools ourselves during the period of installing and adjusting, the other instruments we need should be furnished by the customer for free including hydraulic oil, pipeline, antirust preventer etc. that needed in the installation and adjustment site.

The customer should dispatch the capable person to accept training in the installing site.

2, Training

We are responsible for offering the technical training to user. The training content includes the structure and maintenance of the equipments, control and operation of the equipments. The training lessons are finished in the process of installation and adjustment. Through training, users' technical staff can grasp and the skill of operation and maintenance proficiently, and deal with the general troubles in time.

3, Quality assurance

We guarantee the goods offered are brand-new, unused, with latest design and suitable material made, and we guarantee the specification of the equipments is consonance with the contract.

We are responsible for the fault and damage of the production line caused by our design, technology, manufacture, installation, adjustment and material defect etc that all belong to our responsibility.

4, Maintenance

Offer 12 months maintenance period to the problem that caused by our design, manufacture and the material quality, and offer the relevant parts and effective service for free for above reason. We will offer a widely and favorable technical support, after service all the time after guarantee period.

Packaging&Shipping

|  |  |

|  |  |