VFINE Blowing Machine Selling Points

Save energy, flexible:

Single channel preform in-feed, production capacity of the machine is no less than 2000 bottles/hour per cavity, and the efficiency is high; the equipment combines the advantages of the rotary machine and the linear machine, with a high energy utilization rate and simple and convenient operation.

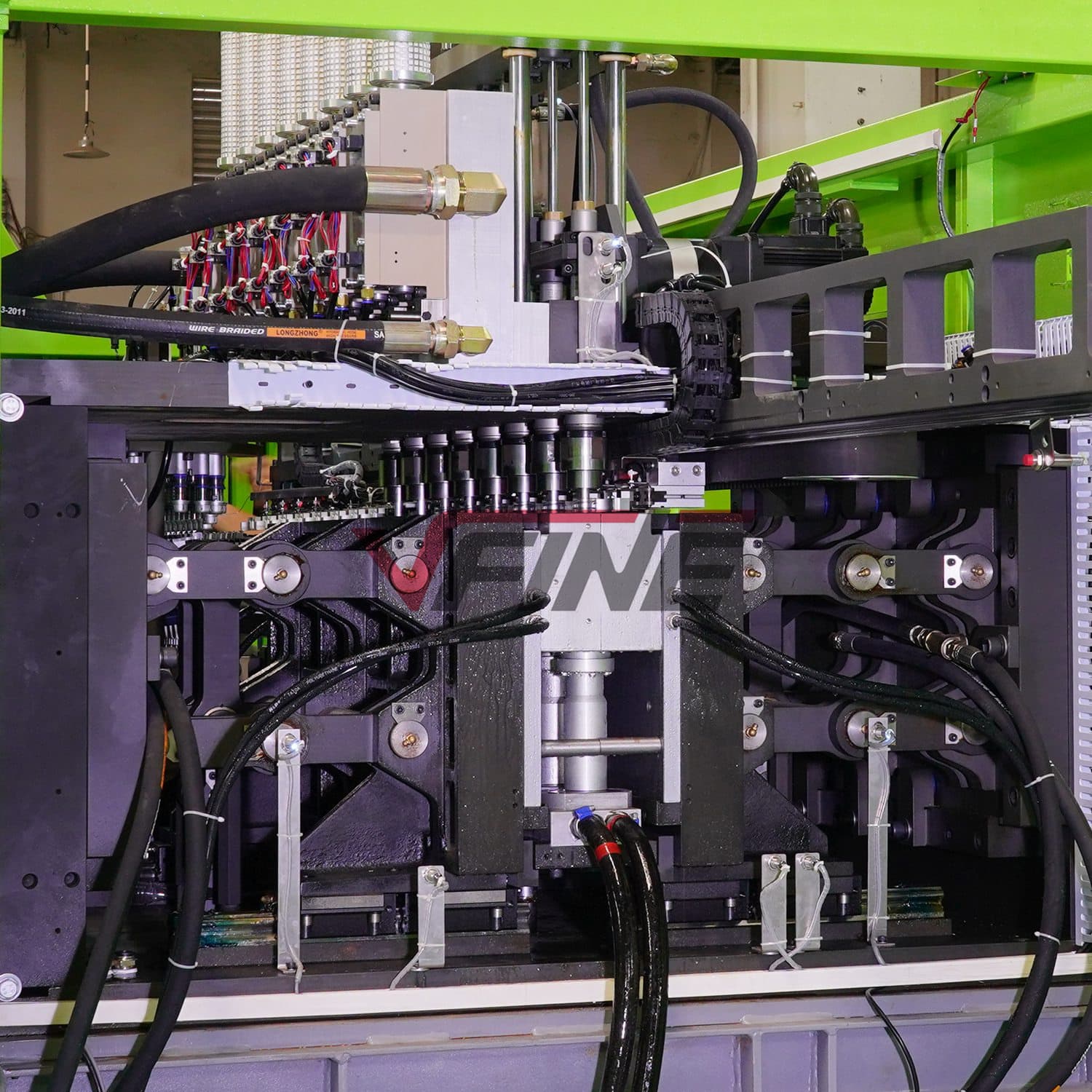

Fast mold change:

Drawer-type mold locking structure, easy and quick mold change, no more than 30 minutes to change the mold.

Intelligent control system, which can finish all parameter settings, equipment operation, and troubleshooting on the touch screen. Stable equipment performance and low maintenance cost.

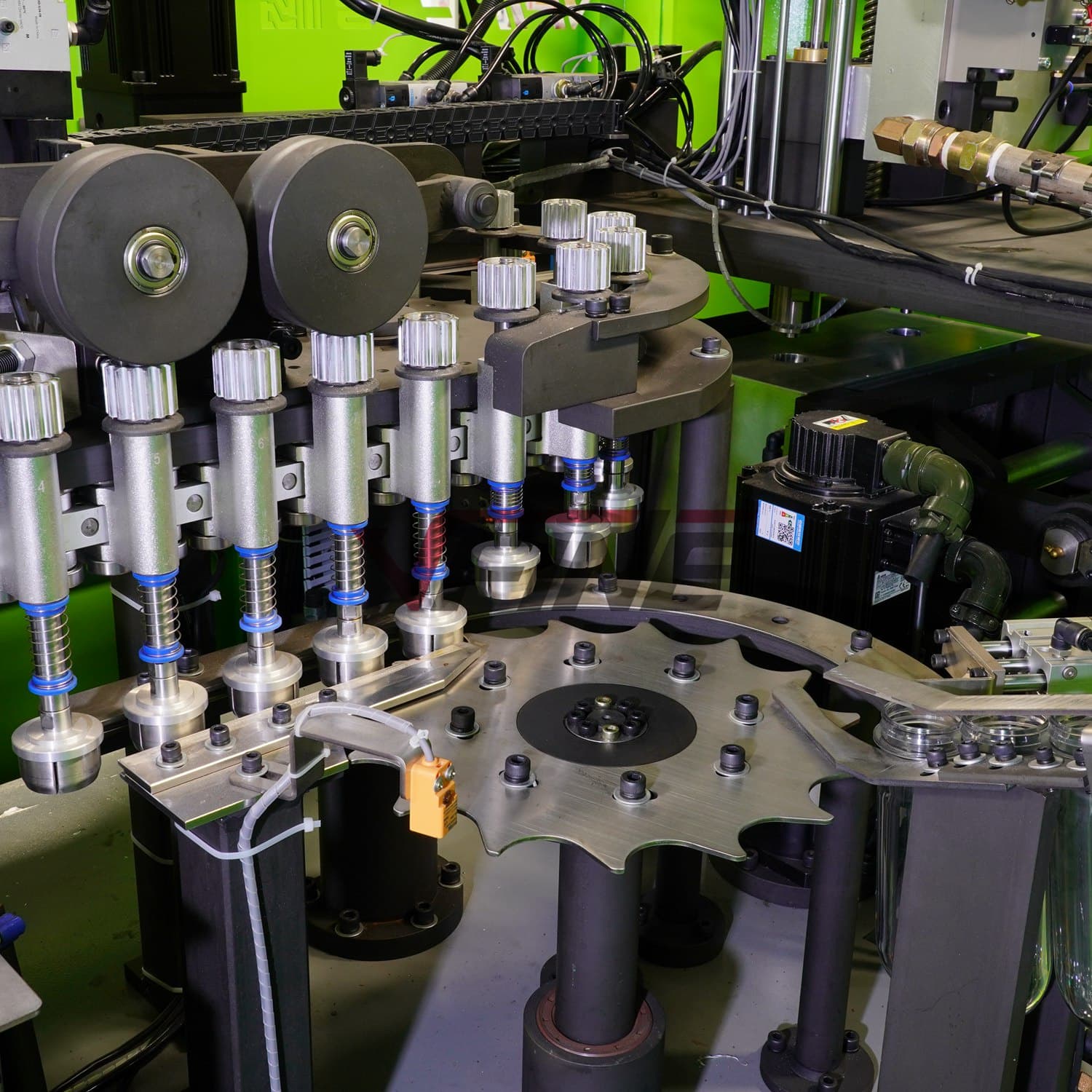

Oil-free preform transfer system, there is no risk of preform getting polluted.

The equipment structure design is compact, oceupying a sm space. Powerful temperature control system can ensure gon ont neating output and ensure the stability of preform heating.

The whole machine frame and clamping plates are annealed; and the plane and hole processing are finished atone time in the CNC to ensure that the machine frame and template are accurate, non-deformed, and durable.

Powerful cooling system to ensure that the thin-walled preform neck bottles and light-weight bottles are not deformed.