Vfine Machine Specialized In Bottle Making Machine Which Provide Turnkey Project Service Since 2001.

(1) The classification and introduction of blowing bottle machine- the extrusion blowing machine

Welcome back to VFINE Blowing Machine Channel. Today We will divide three small articles to talk about the classification of blowing machine. Let's learn about the extrusion blowing machine.

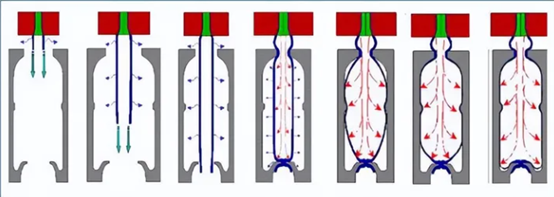

(1) Extrusion blow molding machine is a common type of blow molding machine. It has the advantages of high production efficiency and good product transparency by extruding and blowing the melted plastic into shape. However, due to the large wall thickness of its products, it is often used to produce liquid beverage bottles with wider bottle necks and bodies.

Extrusion-Blow moulding is also called hollow extrusion blow molding. The extruder continuously extrudes hollow tubes, which are cut into small sections using scissors (manual) or cutting devices (automatic), and then moved to the extrusion blow mold to blow and shape.

Advantages: Simple equipment, low investment, and low cost price.

Disadvantages: Uneven bottle neck and poor sealing. LDPE, HDPE and PP are usually used as raw materials, and the permeability of LDPE is much lower than that of HDPE/PP.

Contact Person: Diana Ren

Phone: +86 13823903135

E-Mail: vfine@vfinemachine.com

Add: No 529, Nanhe East road, Nantou Town, Zhongshan City, Guangdong China